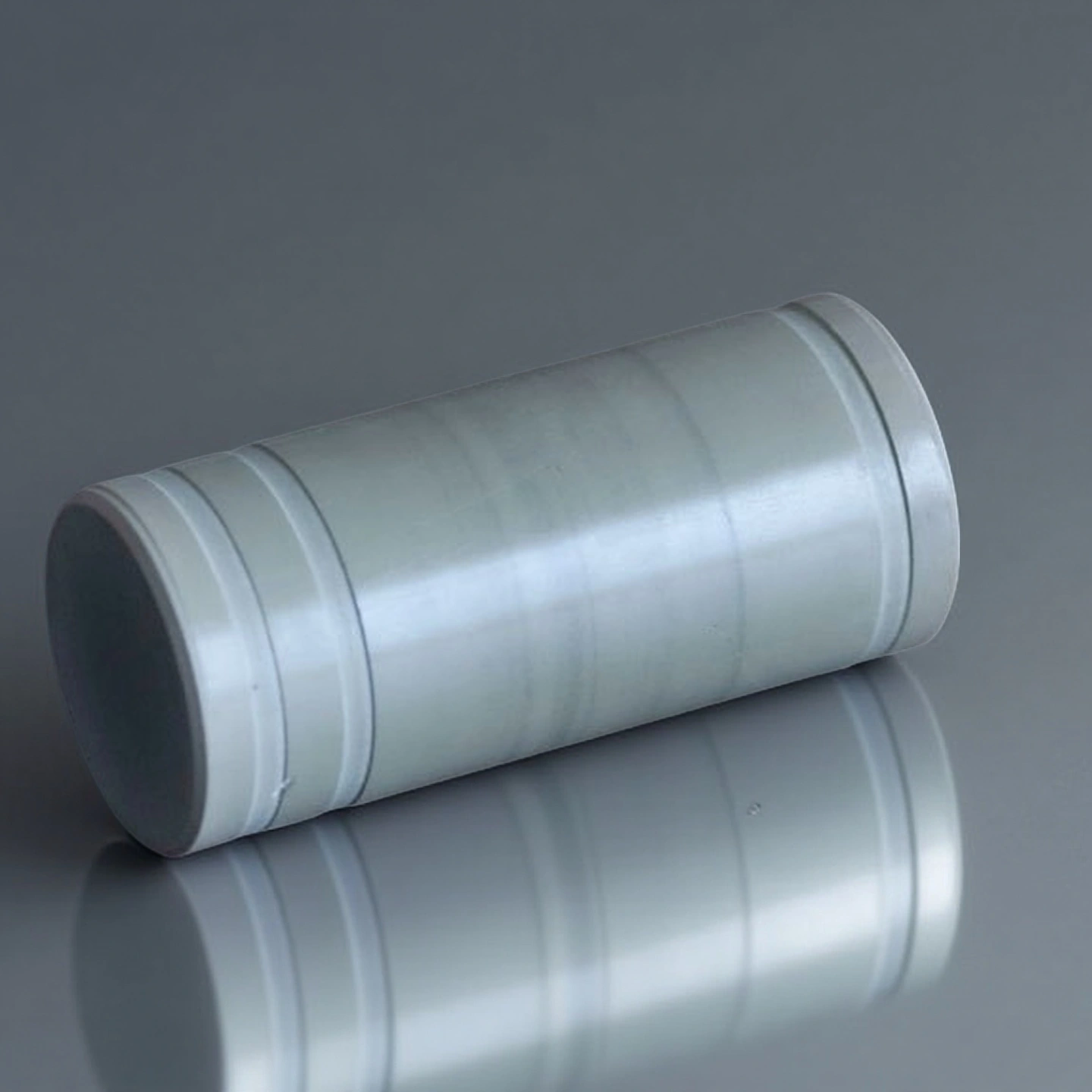

Aluminum nitride ceramic cylinder is a precision-machined cylindrical component fabricated from sintered AlN ceramic and used in assemblies that demand simultaneous high thermal conductivity, electrical insulation, and dimensional stability. In engineering applications, it functions as a support post, insulating spacer, thermal conduit, or structural sleeve inside high-power electronic modules, vacuum systems, and industrial thermal equipment.

Aluminum Nitride Ceramic Cylinder Benefits

-

Thermal management inside compact assemblies

The aluminum nitride ceramic cylinder combines high thermal conductivity (around 170–190 W/m·K) with electrical insulation, allowing engineers to remove heat from busbars, modules or fixtures while keeping circuits isolated. -

Dimensional precision for assembly fit

OD/ID and length can be controlled to typical tolerances of ±0.05–0.10 mm on critical dimensions, supporting press-fit, slip-fit or bolted assemblies without excessive play or stress concentration. -

Stable performance at elevated temperature

The AlN ceramic cylinder maintains mechanical strength and insulation at continuous service temperatures up to about 800–1000 °C in air and higher in inert or vacuum atmospheres, making it suitable for many furnace and heater designs. -

Matched expansion to Si and SiC devices

The coefficient of thermal expansion around 4.5 × 10⁻⁶/K helps reduce thermal mismatch against silicon or silicon carbide chips and substrates, lowering the risk of cracking or solder fatigue in power modules. -

Flexible geometry: solid, hollow, stepped or slotted

Cylinders can be supplied as solid pins, hollow tubes, stepped posts or parts with drilled holes and grooves, so one aluminum nitride ceramic cylinder design can integrate both mechanical support and routing for fasteners or leads.

Aluminum Nitride Cylinder Properties

| Property Content | Unit | Unit | ALN-170 | ALN-200 | ALN-230 |

| Basic Properties | Color | gray | light yellow | light yellow | |

| Density | g/cm³ | 3.2-3.3 | 3.2-3.3 | 3.2-3.3 | |

| Surface Roughness | μm | 0.2-0.75 | 0.2-0.75 | 0.2-0.8 | |

| Camber | length ‰ | ≤3‰ | ≤3‰ | ≤3‰ | |

| Hardness | HV | 1100 | 1100 | 1100 | |

| Thermal Properties | Max Operating Temperature | °C | 1100 | 1100 | 1100 |

| Thermal Conductivity | W/m·K | 170-190 | 190-220 | 220-230 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(20-400°c) | 4-5 | 4-5 | 4-5 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(400-800°c) | 5-6 | 5-6 | 5-6 | |

| Mechanical Properties | Flexural Strength | MPa | 300-400 | 350-450 | 400-500 |

| Tensile Strength | MPa | 200-300 | 250-350 | 280-380 | |

| Compressive Strength | MPa | 2000-3000 | 2200-3200 | 2500-3500 | |

| Electrical properties | Dielectric Constant | at 1MHz | 8-9 | 8-9 | 8-9 |

| Dielectric strength | KV/mm | ≥15 | ≥15 | ≥15 | |

| Volume resistivity | 20℃ Ω.cm | ≥1014 | ≥1014 | ≥1014 |

Aluminium Nitride Ceramic Cylinder Specifications

| Aluminum Nitride Ceramic Cylinder | ||||

| Item No. | Outer Diameter(mm) | Height(mm) | Purity(%) | Thermal conductivity(w/(m·K)) |

| AT-AIN-Anc001 | 20 | 200 | 92-99 | 170-230 |

| AT-AIN-Anc002 | 30 | 150 | 92-99 | 170-230 |

| AT-AIN-Anc003 | 50 | 100 | 92-99 | 170-230 |

| AT-AIN-Anc004 | 70 | 120 | 92-99 | 170-230 |

| AT-AIN-Anc005 | 80 | 180 | 92-99 | 170-230 |

| AT-AIN-Anc006 | 90 | 300 | 92-99 | 170-230 |

| AT-AIN-Anc007 | 120 | 350 | 92-99 | 170-230 |

| AT-AIN-Anc008 | 150 | 400 | 92-99 | 170-230 |

AlN Ceramic Cylinder Packaging

- Each aluminum nitride ceramic cylinder is first wrapped in clean, non-shedding protective film or bag to avoid chipping and contamination during handling.