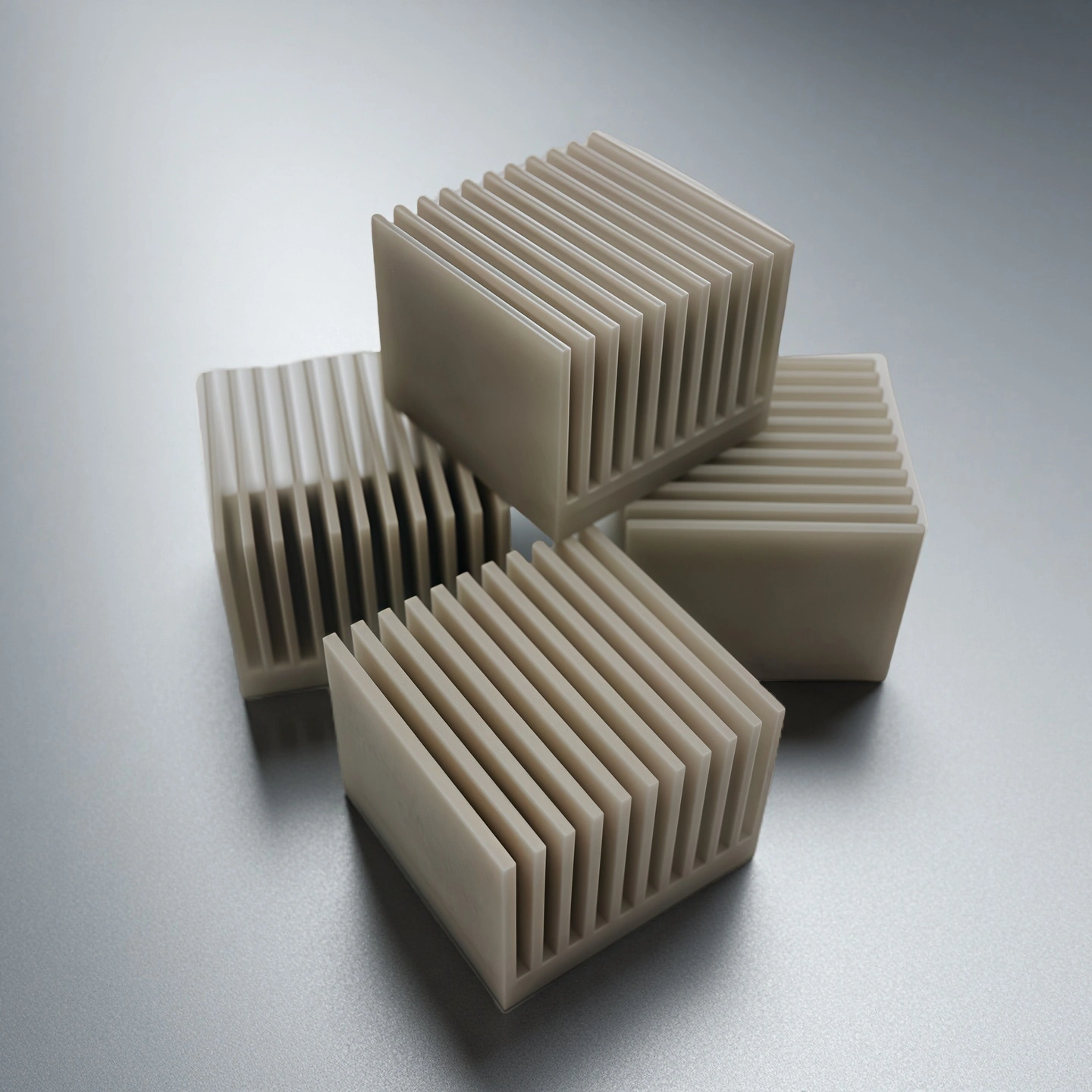

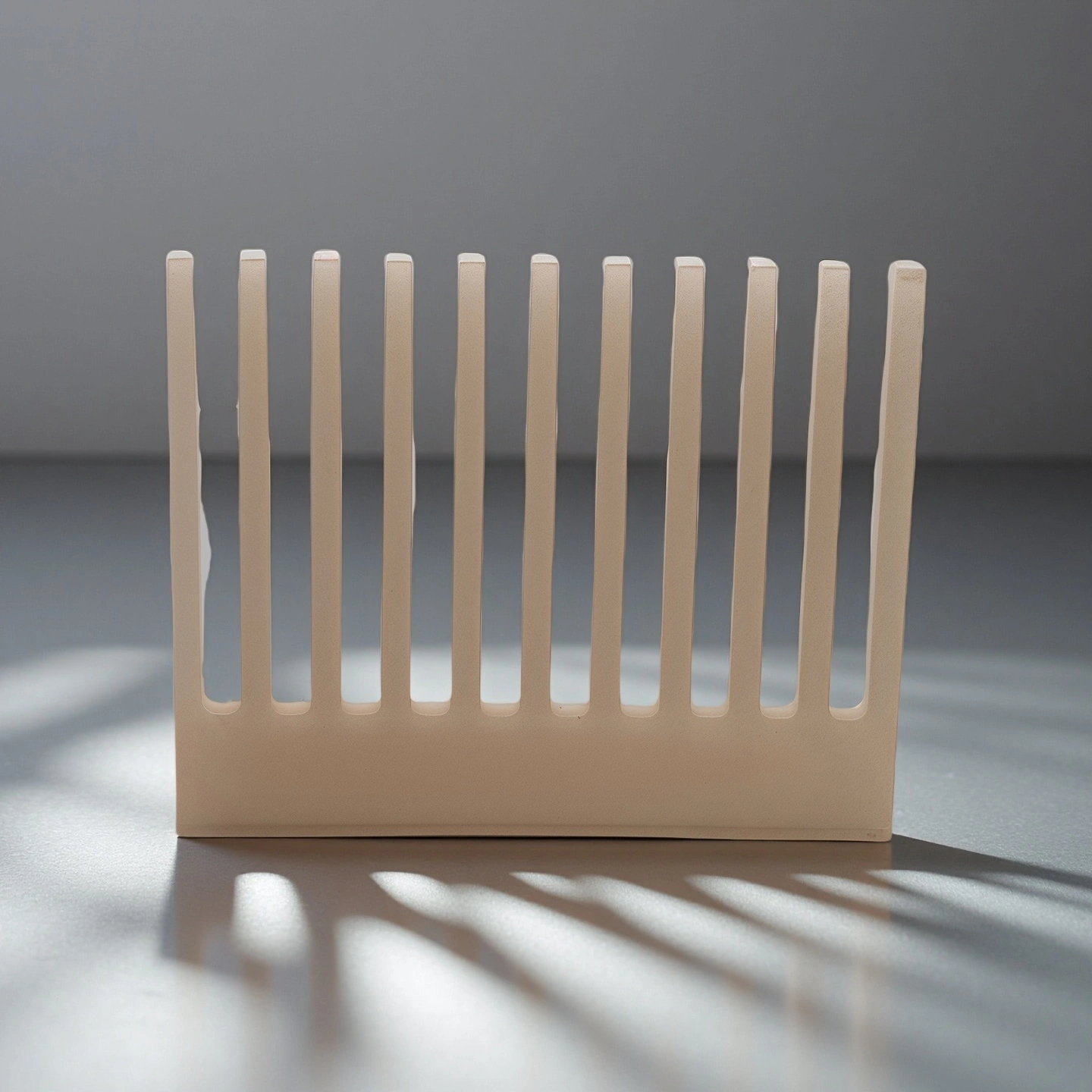

An aluminum nitride ceramic heat sink is a precision-machined AlN thermal management component that combines high thermal conductivity with intrinsic electrical insulation, enabling efficient heat spreading and heat transfer for power semiconductor, LED/LD, and RF devices while maintaining dielectric isolation and dimensional stability under thermal cycling.

Aluminum Nitride Ceramic Heat Sink Benefits

-

High Heat Flux Handling in Compact Footprints

The aluminum nitride ceramic heat sink provides thermal conductivity in the 160–180 W/m·K range, allowing designers to move from larger alumina-based layouts to smaller, higher power density modules. -

Electrical Insulation with Stable Dielectric Performance

The AlN ceramic heat sink combines high breakdown strength and stable dielectric constant, which supports reliable isolation between live copper traces and grounded baseplates. -

Tight Flatness and Thickness Tolerance for Reliable Assembly

The aluminum nitride ceramic heat sink can be ground to tight thickness and flatness tolerances so that solder layers and thermal interface materials achieve consistent bond line thickness and low thermal resistance. -

Matched Thermal Expansion for Silicon and Power Packages

The coefficient of thermal expansion of the AlN heat sink is closer to silicon and many power packages than metals, which helps reduce thermo-mechanical stress and improves thermal cycling performance. -

Flexible Copper Patterns and Surface Finishes

The AlN ceramic heat sink can be supplied bare or with copper, Ni/Au or Ag metallization and patterned pads, so it can serve as both heat spreader and circuit substrate in one component.

AlN Ceramic Heat Sink Properties

| Property Content | Unit | Unit | ALN-170 | ALN-200 | ALN-230 |

| Basic Properties | Color | gray | light yellow | light yellow | |

| Density | g/cm³ | 3.2-3.3 | 3.2-3.3 | 3.2-3.3 | |

| Surface Roughness | μm | 0.2-0.75 | 0.2-0.75 | 0.2-0.8 | |

| Camber | length ‰ | ≤3‰ | ≤3‰ | ≤3‰ | |

| Hardness | HV | 1100 | 1100 | 1100 | |

| Thermal Properties | Max Operating Temperature | °C | 1100 | 1100 | 1100 |

| Thermal Conductivity | W/m·K | 170-190 | 190-220 | 220-230 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(20-400°c) | 4-5 | 4-5 | 4-5 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(400-800°c) | 5-6 | 5-6 | 5-6 | |

| Mechanical Properties | Flexural Strength | MPa | 300-400 | 350-450 | 400-500 |

| Tensile Strength | MPa | 200-300 | 250-350 | 280-380 | |

| Compressive Strength | MPa | 2000-3000 | 2200-3200 | 2500-3500 | |

| Electrical properties | Dielectric Constant | at 1MHz | 8-9 | 8-9 | 8-9 |

| Dielectric strength | KV/mm | ≥15 | ≥15 | ≥15 | |

| Volume resistivity | 20℃ Ω.cm | ≥1014 | ≥1014 | ≥1014 |

AlN Ceramic Heat Sink Specifications

| Item No. | Diameter (mm) | Thickness (mm) | Purity |

| AT-AIN-SR1001 | Customize | ||

AlN Heat Sink Packaging

- Each aluminum nitride ceramic heat sink is separated with protective paper or film and stacked in partitioned trays or vacuum sealed bags to prevent scratching of functional surfaces.