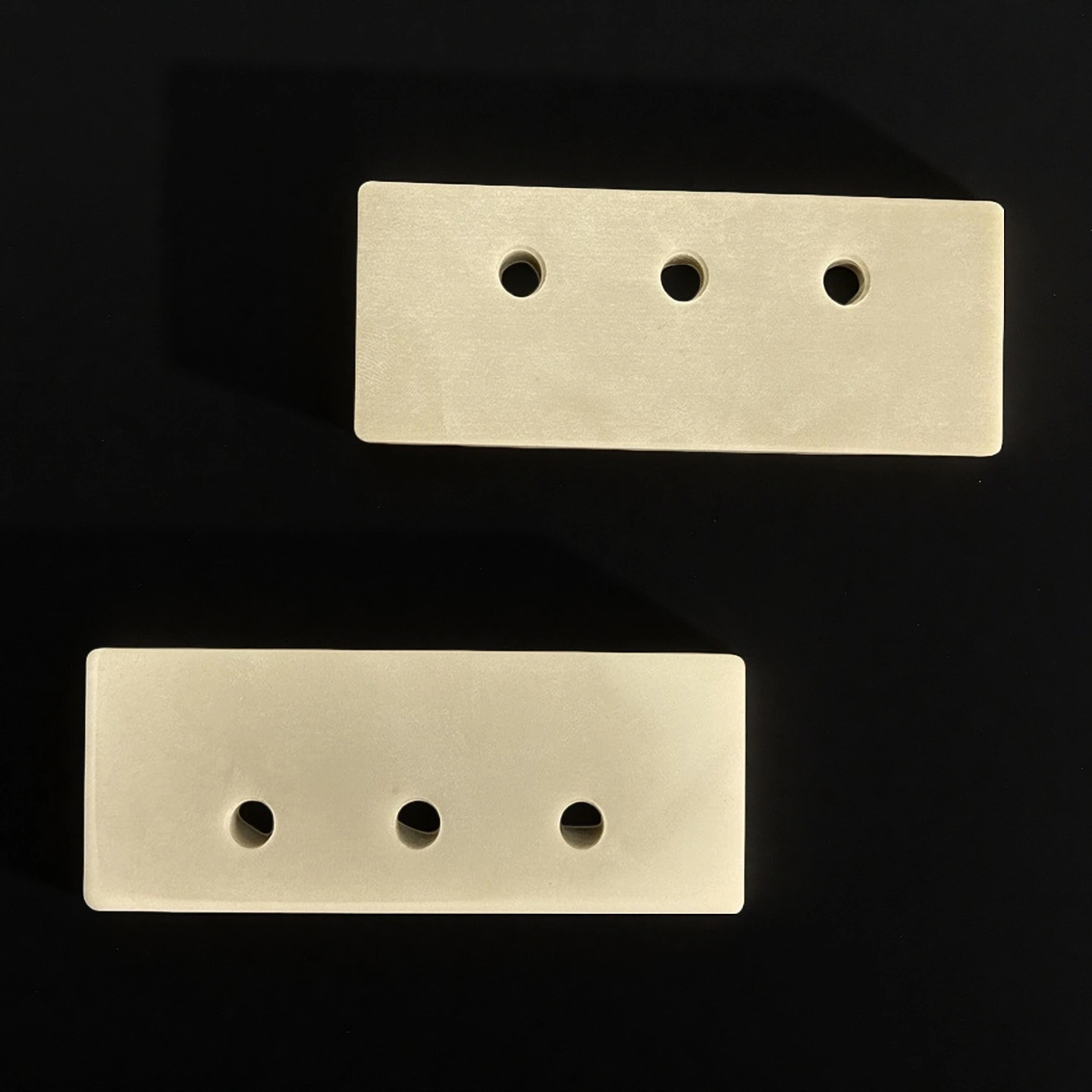

Aluminum nitride precision parts are machined ceramic components manufactured from high thermal conductivity AlN. They combine efficient heat spreading with high electrical insulation and a thermal expansion coefficient close to silicon, making them suitable for power electronics, RF and optoelectronic assemblies where compact layouts and high power density are required.

Aluminum Nitride Precision Parts Benefits

-

Tight dimensional control – Typical tolerances down to ±0.05 mm on critical aluminum nitride precision features, supporting accurate module assembly and repeatable fits.

-

High thermal conductivity in compact geometries – Machined paths, slots and cavities allow aluminum nitride precision parts to act as efficient heat spreaders while keeping package size small.

-

Electrical insulation with silicon-like expansion – Aluminum nitride precision parts provide high dielectric strength with a thermal expansion coefficient close to Si and GaN, reducing stress on solder joints and chips.

-

Stable under high temperature and cycling – Dense AlN microstructure gives good resistance to thermal shock and long-term thermal cycling in power electronics and industrial heaters.

-

Geometry flexibility for integration – Through-holes, counterbores, recesses and stepped surfaces can be integrated into a single aluminum nitride precision part, reducing piece count in the assembly.

Aluminum Nitride Precision Ceramic Parts Properties

| Property Content | Unit | Unit | ALN-170 | ALN-200 | ALN-230 |

| Basic Properties | Color | gray | light yellow | light yellow | |

| Density | g/cm³ | 3.2-3.3 | 3.2-3.3 | 3.2-3.3 | |

| Surface Roughness | μm | 0.2-0.75 | 0.2-0.75 | 0.2-0.8 | |

| Camber | length ‰ | ≤3‰ | ≤3‰ | ≤3‰ | |

| Hardness | HV | 1100 | 1100 | 1100 | |

| Thermal Properties | Max Operating Temperature | °C | 1100 | 1100 | 1100 |

| Thermal Conductivity | W/m·K | 170-190 | 190-220 | 220-230 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(20-400°c) | 4-5 | 4-5 | 4-5 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(400-800°c) | 5-6 | 5-6 | 5-6 | |

| Mechanical Properties | Flexural Strength | MPa | 300-400 | 350-450 | 400-500 |

| Tensile Strength | MPa | 200-300 | 250-350 | 280-380 | |

| Compressive Strength | MPa | 2000-3000 | 2200-3200 | 2500-3500 | |

| Electrical properties | Dielectric Constant | at 1MHz | 8-9 | 8-9 | 8-9 |

| Dielectric strength | KV/mm | ≥15 | ≥15 | ≥15 | |

| Volume resistivity | 20℃ Ω.cm | ≥1014 | ≥1014 | ≥1014 |

Aluminium Nitride Precision Parts Specifications

| Processing size range of AIN Parts | |||

| Item No. | Outer Diameter(mm) | Inner Diameter(mm) | Height(mm) |

| AT-AIN-JG001 | 2-500 | 0.5-400 | 0.1-450 |

Aluminum Nitride Precision Components Packaging

- Aluminum nitride precision parts are separated with soft dividers or cavity trays to prevent edge chipping and face scratching during transport.