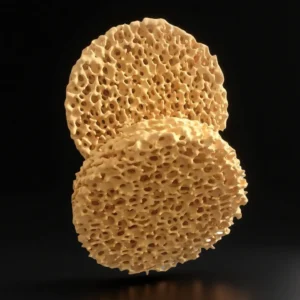

Magnesia ceramic foam filters are porous refractory components made from high-purity magnesium oxide (MgO), specifically developed to purify molten magnesium and other reactive metal alloys such as nickel or zinc. They are designed with a three-dimensional open-cell foam structure that allows the metal to pass through while effectively trapping oxide films, non-metallic inclusions, and slag particles, improving the cleanliness and mechanical quality of the final casting.

Magnesia Ceramic Foam Filters Benefits

- Excellent Chemical Resistance – Stable in contact with molten magnesium and nickel alloys.

- Uniform Pore Structure – Ensures consistent filtration efficiency and low turbulence.

- High Mechanical Strength – Resists metal flow impact during pouring.

- Precise Dimensional Control – ± 0.5 mm tolerance for easy mold integration.

- Customizable Grades – 10–60 PPI available for different flow rates and purity requirements.

Properties of MgO Foam Filters

|

Parameter |

Alumina (Aluminium Oxide) |

Silicon Carbide |

Zirconia (Zirconium Oxide) |

Magnesia (Magnesium Oxide) |

|

Raw Material |

Alumina |

Silicon Carbide |

Zirconia |

Magnesia |

|

Color |

White |

Black-Gray |

Yellow |

Dark Yellow |

|

Pore Density |

8-60 ppi |

8-60 ppi |

8-60 ppi |

8-60 ppi |

|

Porosity |

80-90% |

80-90% |

80-90% |

80-90% |

|

Refractoriness |

≤1100℃ |

≤1500℃ |

≤1700℃ |

≤1000℃ |

|

Bending Strength |

>0.6Mpa |

>0.8Mpa |

>1.0Mpa |

>0.6Mpa |

|

Compressive Strength |

>0.8Mpa |

>0.9Mpa |

>1.2Mpa |

>0.8Mpa |

|

Bulk Density |

0.3-0.45g/cm³ |

0.35-0.5g/cm³ |

0.9-1.5g/cm³ |

0.35-0.5g/cm³ |

|

Thermal Shock Resistance |

6 times/1100℃ |

6 times/1100℃ |

6 times/1100℃ |

6 times/1100℃ |

|

Applications |

Aluminium alloys and other non-ferrous metal alloys |

Ductile iron, Malleable cast iron, Gray cast iron, and other cast iron |

High melting point metal alloys, such as steel, alloy steel, stainless steel, etc. |

Magnesium and high-activity alloys |

Mgo Ceramic Foam Filters Specifications

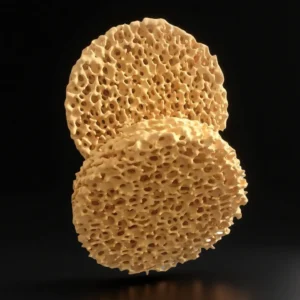

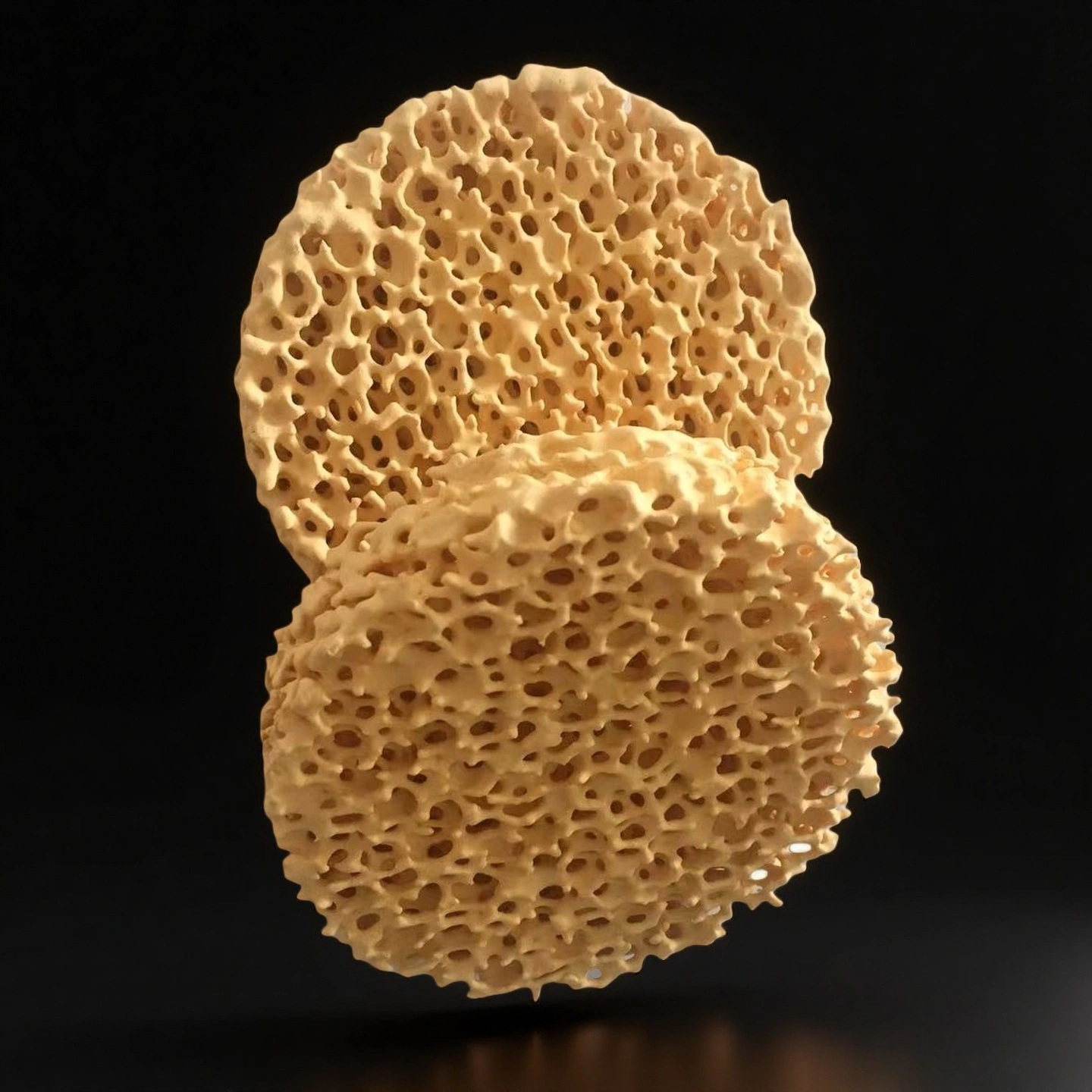

Type 1: Magnesia Ceramic Foam Filter Round

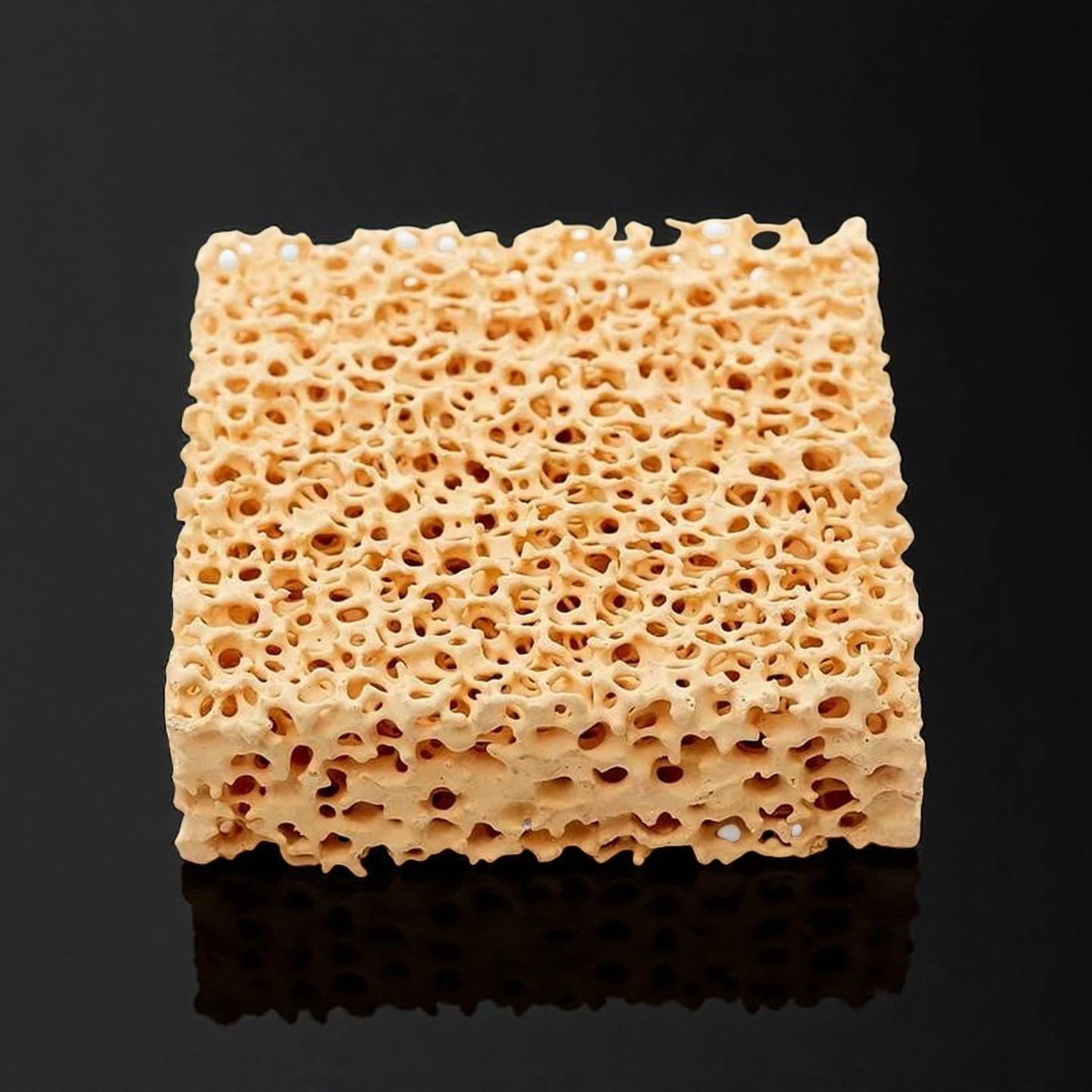

Type 2: Magnesia Ceramic Foam Filter Square

|

Magnesia Ceramic Foam Filter Square |

|

Item NO. |

Length (mm) |

Width (mm) |

Thickness (mm) |

Pore Density PPI |

Porosity(%) |

|

AT-MO-PM2001 |

40 |

40 |

10 |

10/20/30/40/50/60 |

80~90 |

|

AT-MO-PM2002 |

40 |

40 |

22 |

10/20/30/40/50/60 |

80~90 |

|

AT-MO-PM2003 |

50 |

50 |

10 |

10/20/30/40/50/60 |

80~90 |

|

AT-MO-PM2004 |

50 |

50 |

22 |

10/20/30/40/50/60 |

80~90 |

|

AT-MO-PM2005 |

50 |

50 |

30 |

10/20/30/40/50/60 |

80~90 |

|

AT-MO-PM2006 |

75 |

50 |

22 |

10/20/30/40/50/60 |

80~90 |

|

AT-MO-PM2007 |

75 |

75 |

22 |

10/20/30/40/50/60 |

80~90 |

|

AT-MO-PM2008 |

100 |

100 |

22 |

10/20/30/40/50/60 |

80~90 |

|

AT-MO-PM2009 |

150 |

100 |

22 |

10/20/30/40/50/60 |

80~90 |

|

AT-MO-PM2010 |

150 |

150 |

22 |

10/20/30/40/50/60 |

80~90 |

|

AT-MO-PM2011 |

40-300 |

40-300 |

10-50 |

10/20/30/40/50/60 |

80~90 |

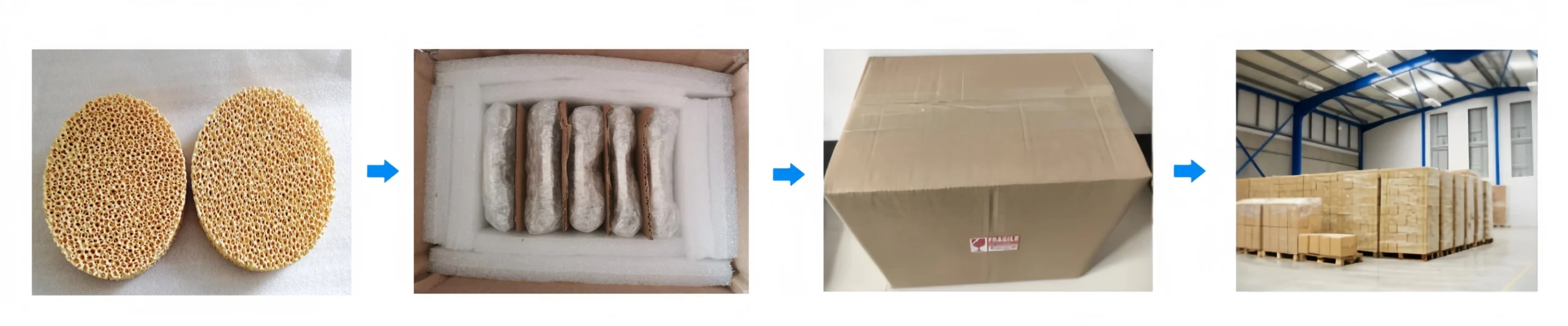

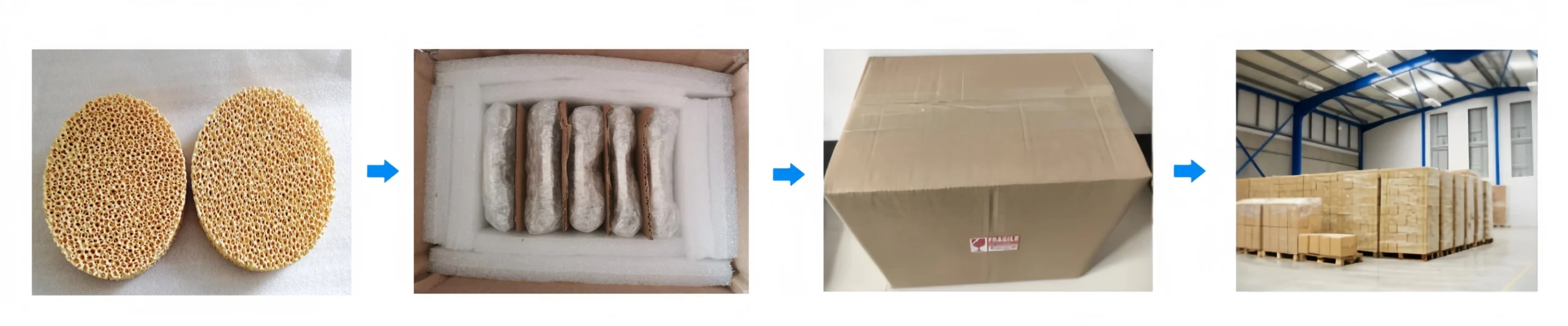

MgO Foam Filters Packaging

- Each filter is individually packed in shock-resistant foam and sealed in moisture-proof bags. Bulk orders are shipped in reinforced wooden crates.

Magnesia Ceramic Foam Filters Applications

MgO foam filters are specialized for molten magnesium and reactive metal casting, where traditional alumina or silica filters fail due to chemical incompatibility. Their exceptional stability and filtration precision make them essential in automotive, aerospace, and foundry engineering sectors.

-

Magnesium Alloy Casting — Automotive & Industrial Components

✅Key Advantages

1. Excellent resistance to reactive molten magnesium up to 1100 °C, preventing violent oxidation.

2. Uniform open-pore structure removes oxide films and non-metallic inclusions ≥ 20 µm.

3. Improves surface finish and mechanical strength of castings such as gearbox housings, steering columns, and laptop frames.

✅ Problem Solved

A European die-casting factory reported that using ADCERAX MgO foam filters reduced inclusion-related rework by 72%, cutting total defect rate from 6.8% → 1.9%. The change shortened polishing time and stabilized casting flow across multiple molds.

-

Nickel-Based & Superalloy Precision Casting — Aerospace & Turbine Industry

✅Key Advantages

1. Prevents micro-inclusion-induced fatigue cracks in turbine blades, nozzles, and heat-resistant alloy components.

2. Maintains filtration performance across repeated pouring cycles (≥ 6 thermal shocks at 1100 °C).

3. Ensures chemical inertness — no MgO–NiO reaction or melt contamination.

✅ Problem Solved

An Asian aerospace alloy foundry using MgO filters achieved a 40% reduction in defect scrap, improving tensile strength uniformity by 12% in precision-cast turbine parts.

-

Foundry Consumables Integration — Metal Filtration & Gating Systems

✅Key Advantages

1. Compatible with standard filter cups, gating boxes, and ceramic frames.

2. Reduces slag carry-over and flow turbulence, extending the life of pouring basins and refractory linings.

3. Enables foundry distributors to create full consumable kits (filter + insulation + pouring cup + cover plate).

✅ Problem Solved

A Korean foundry material distributor standardized ADCERAX magnesia filters across their magnesium alloy customer base. As a result, their customers reported 15–20% faster setup and 30% lower inventory complexity due to unified part sizing (50 × 50 mm / 75 × 75 mm modules).

Mgo Ceramic Foam Filters Usage Instructions

Proper use of magnesia ceramic foam filters ensures consistent casting performance, longer service life, and higher yield.

Follow the guidelines below to maximize performance and prevent production downtime.

-

Installation

1. Place the filter securely into the mold gating cup with the textured (inlet) side facing upward.

2. Ensure full contact between filter edges and the refractory lining to prevent molten metal bypass.

3. Avoid applying mechanical stress or impact to the filter during installation — its open-cell structure is strong yet brittle under point pressure.

4. If using a frame or holder, align the centre position with the metal stream path to maintain laminar flow.

5. Apply a thin layer of refractory cement or clay sealant around the filter edge to improve seating stability.

-

Usage

1. Preheat the filter to 200–300 °C (minimum 250 °C recommended) before pouring to prevent thermal shock cracking.

2. When preheating, ensure even temperature distribution; localized flame heating may cause micro-cracks.

3. Maintain steady head pressure and controlled pouring rate during metal flow to achieve uniform filtration.

4. For high-reactivity magnesium melts, avoid long holding time above the filter — continuous flow minimizes erosion.

5. Use proper PPI rating based on casting type:

a. Coarse filters (10–20 PPI) for large, thick castings requiring high metal throughput.

b. Fine filters (30–60 PPI) for precision parts needing superior surface finish.

-

Storage

1. Store filters in a dry, ventilated area with relative humidity below 60 %.

2. Avoid direct exposure to moisture or large temperature fluctuations that could weaken ceramic bonds.

3. Stack horizontally in even layers, not exceeding 20 layers per pallet, to prevent warping or edge cracking.

4. Keep filters in their original packaging until use to prevent dust contamination and accidental chipping.

-

Cleaning / Maintenance

1. Single-use recommended: Do not reuse filters exposed to metal infiltration, erosion, or slag adhesion.

2. After casting, allow the filter to cool gradually with the mould to avoid thermal shock breakage.

3. Once metal residue solidifies, dispose of the filter safely according to local refractory waste regulations.

4. Inspect unused filters before each pour — replace any with visible cracks or corner damage.

-

Common User Errors & Solutions

1. Issue: Filter cracks during pouring

Cause: No or insufficient preheating.

Solution: Always preheat uniformly to ≥ 250 °C; for large castings, extend soak time to 15 minutes.

2. Issue: Inclusions remain in the melt

Cause: PPI too low or flow rate too high.

Solution: Select a higher PPI (≥ 30) or reduce pouring speed to enhance filtration efficiency.

3. Issue: Filter floats or shifts during pouring

Cause: Improper seating or lack of frame support.

Solution: Use a fitted metal frame or apply clay sealant to secure the position.

4. Issue: Filter erosion after several pours

Cause: Excessive melt superheat or long holding time.

Solution: Control pouring temperature below 1050 °C and maintain continuous metal flow.

5. Issue: Edge leakage between the filter and mould wall

Cause: Incomplete contact with the refractory cup.

Solution: Apply refractory paste along the contact surface and verify tight sealing.