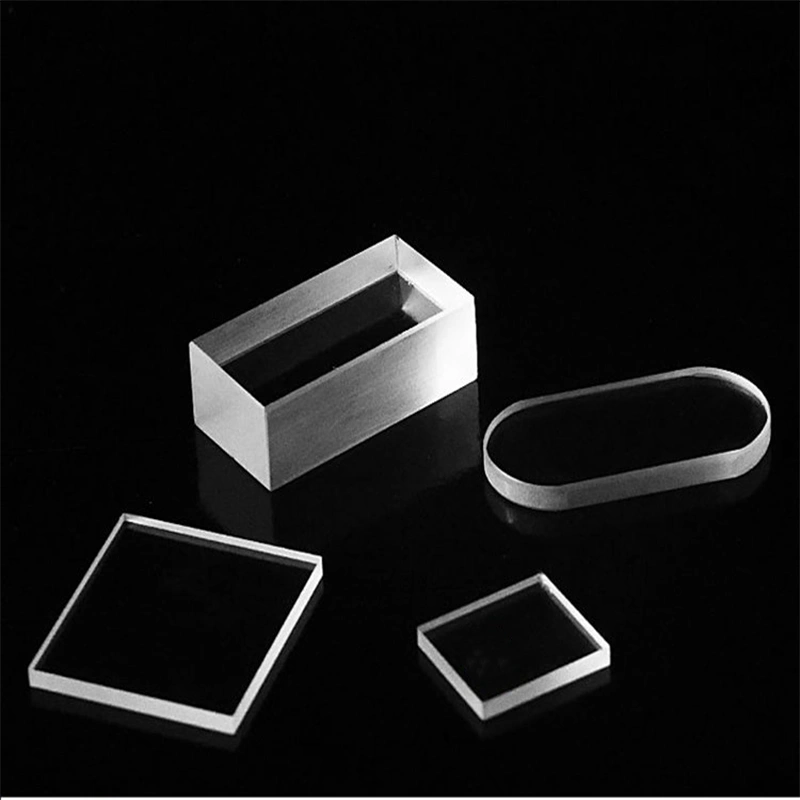

Sapphire optical glass windows are widely used in high-temperature, vacuum, and optical systems due to their exceptional hardness, thermal resistance, and broad-spectrum transmission. These windows are ideal for laser systems, vacuum chambers, medical imaging devices, and UV/IR detection equipment. With excellent surface flatness and chemical durability, sapphire windows ensure stable optical performance in demanding environments.

Sapphire Optical Glass Window Benefits

- Low-loss optics at target wavelengths — AR stacks tuned to 355/532/633/785/1064 nm or wideband VIS–NIR reduce reflection and help maintain power budget.

- Mechanical durability in harsh paths — High hardness and edge-strength options minimize chip-induced failure during repeated cleaning and handling.

- Seal-ready geometries — Step edges, flatness-controlled seats and defined chamfers improve O-ring/metal gasket sealing consistency in CF/KF/ISO hardware.

- Orientation control — C-cut windows reduce birefringence for polarization-sensitive instruments and laser delivery heads.

- Thick pressure variants — 8–20 mm thick formats available for high-pressure or deep-water housings with guided thickness selection.

Sapphire Optical Glass Window Properties

| Property | Value |

| Material | Al2O3 (monocrystalline structure) |

| Purity | 99.999% |

| Max. Working Temperature | 1950℃ |

| Transmissivity | >86% (280-3500nm) |

| Refractive Index (λ ≈ 546 nm) | 1.76 |

| Density | 3.98-4.1g/cm3 |

| Hardness | 1700Hv |

| Compressive Strength | 2100MPa |

| Tensile Strength | 200MPa |

| Bending Strength | 445MPa |

| Elasticity Modulus | 380GPa |

| Poisson's Ratio | 0.28 |

| Thermal Conductivity | 28-32W/m*K |

| Thermal Expansion Coefficient | 6*10-6/K |

| Refractive Index | 1.76 |

| Volume Resistivity | >1.5*1016Ohm*cm |

| Dielectric Strength | 48KV/mm |

| Lattice Constant (a, c) | a = 4.758 Å, c = 12.991 Å |

| Double-Side Polished Surface | Ra < 0.5 nm |

| Decomposition Point | > 2000 °C (in air) |

Sapphire Optical Glass Window Specifications

| Item No. | Size(Dia.×Length) | Direction | Application |

| AT-CKP-001 | 10.0×2.0mm | Random | IR |

| AT-CKP-002 | 12.0×1.0mm | Random | IR |

| AT-CKP-003 | 12.0×2.0mm | Random | IR |

| AT-CKP-004 | 12.0×4.0mm | Random | IR |

| AT-CKP-005 | 15.0×2.0mm | Random | IR |

| AT-CKP-006 | 18.0×4.0mm | Random | IR |

| AT-CKP-007 | 20.0×2.0mm | Random | IR |

| AT-CKP-008 | 25.0×0.5mm | Random | IR |

| AT-CKP-009 | 25.0×1.0mm | Random | IR |

| AT-CKP-010 | 25.0×2.0mm | Random | IR |

| AT-CKP-011 | 25.4×1.0mm | Random | IR |

| AT-CKP-012 | 26.0×1.0mm | Random | IR |

| AT-CKP-013 | 35.0×2.0mm | Random | IR |

Sapphire Optical Glass Window Packaging

- Clean handling: lint-free interleaf, individual clean pouch, orientation mark visible.

- Protection: each window in foam carrier; batch trays with vacuum foam inserts for mixed sizes.