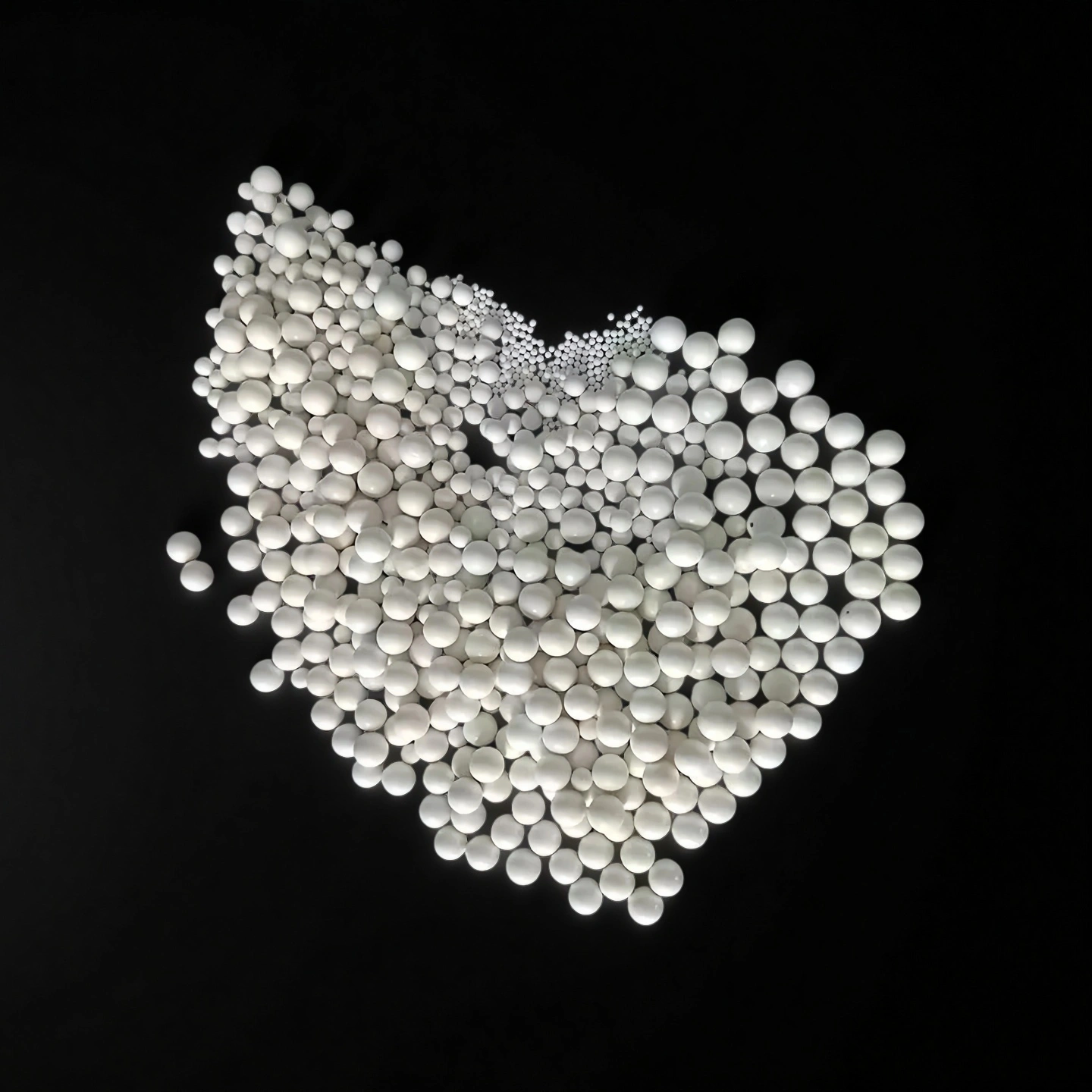

Zirconia Toughened Alumina (ZTA) Ceramic Grinding Balls are advanced composite grinding media made by combining alumina (Al₂O₃) with a controlled percentage of zirconia (ZrO₂). The zirconia phase acts as a toughening agent, significantly enhancing the material’s fracture toughness, wear resistance, and impact strength while maintaining alumina’s chemical stability and low contamination characteristics.

ZTA Ceramic Grinding Balls Benefits

- Low wear rate vs. 90–92% alumina → longer run time, fewer additions.

- Composite toughness → reduced micro-fracture/fragment risk in high-shear mills.

- Mid-density efficiency → effective energy transfer without full-zirconia pump penalty.

- Clean grinding → minimized metallic/ceramic contamination for color/electrical specs.

- Size-to-target linkage → media size rules enable predictable D50/D90 outcomes.

Zirconia Toughened Alumina Ceramic Grinding Balls Properties

| Property | Unit | Alumina (99%) | ZTA (Zirconia Toughened Alumina) | Y-TZP Zirconia |

| Fracture Toughness (KIC) | MPa·m¹⁄² | 5 | 7 – 9 | 6 – 10 |

| Hardness (HV10) | GPa | 8.9 | 9 – 10 (≈ 90 HV) | 12 – 14 |

| Flexural Strength | MPa | 400 | 650 – 800 | 800 – 1200 |

| Density | g/cm³ | 3.9 | 4.0 – 4.3 | 6.0 |

| Relative Wear Rate | — | 1.0 | 0.45 – 0.55 | 0.2 |

| Thermal Expansion Coefficient (RT – 800 °C) | ×10⁻⁶ /K | 8.0 | 8.5 – 9.0 | 10 – 11 |

| Thermal Conductivity (RT) | W/m·K | 25 | 22 – 24 | 2 – 3 |

| Maximum Working Temperature | °C | 1600 | 1450 – 1500 | 1000 – 1200 |

| Dielectric Strength | kV/mm | 12 | 11 – 13 | 9 – 11 |

| Surface Roughness (Ground face) | µm Ra | 0.4 – 1.2 | 0.3 – 0.8 | 0.2 – 0.6 |

| Flatness (after grinding) | mm/300 mm | ≤ 0.4 | ≤ 0.3 | ≤ 0.2 |

ZTA Ceramic Grinding Balls Specifications

| ZTA Ceramic Grinding Balls | ||

| Item No. | Diameter(mm) | AL203+Zr02(Purity) |

| AT-ZTA-Q1001 | 0.5-1 | 26%+70% |

| AT-ZTA-Q1002 | 1-1.5 | 26%+70% |

| AT-ZTA-Q1003 | 2 | 26%+70% |

| AT-ZTA-Q1004 | 2.5 | 26%+70% |

| AT-ZTA-Q1005 | 3 | 26%+70% |

| AT-ZTA-Q1006 | 3.5 | 26%+70% |

| AT-ZTA-Q1007 | 4 | 26%+70% |

| AT-ZTA-Q1008 | 5.5 | 26%+70% |

| AT-ZTA-Q1009 | 6 | 26%+70% |

| AT-ZTA-Q1010 | 8 | 26%+70% |

| AT-ZTA-Q1011 | 9 | 26%+70% |

| AT-ZTA-Q1012 | 10 | 26%+70% |

| AT-ZTA-Q1013 | 13 | 26%+70% |

| AT-ZTA-Q1014 | 15 | 26%+70% |

| AT-ZTA-Q1015 | 20 | 26%+70% |

| AT-ZTA-Q1016 | 25 | 26%+70% |

| AT-ZTA-Q1017 | 30 | 26%+70% |

Zirconia-toughened Alumina Ball Packaging

- Double-lined inner bags in sealed drums or heavy-duty cartons.