Who We Are

ADCERAX® is a China-based advanced technical ceramics manufacturer serving industrial engineering teams worldwide.

Factory-direct production integrates ceramic processing, precision machining, inspection, and export logistics in one workflow.

The goal is simple that deliver ceramic components that behave predictably under thermal, mechanical, electrical, and chemical stress.

Brand

International Export Identity

Manufacturing

Dual-Base Production System

Certification

Unified Legal Entity

Corporate Structure :

ADCERAX® is the international export brand of HUNAN ATCERA CO., LTD.

HUNAN ATCERA CO., LTD.

(Parent Company)

Liling Factory

(Production)

Pingxiang Factory

ADCERAX®

(Export Brand)

Production is managed through two manufacturing bases:

• Liling Factory — Alumina, Zirconia, specialty ceramics

• Pingxiang Factory — Silicon carbide, silicon nitride, high-temperature ceramics

What We Do

Standard supply and custom fabrication—both managed with an engineering-first workflow.

Projects start with technical review, then move to prototype or production with defined inspection checkpoints.

If you can share a PDF drawing or sample photo, include mating parts and assembly notes. It prevents avoidable revisions later.

Stable supply for recurring industrial requirements, with consistent dimensions and material behavior.

Repeat orders

Fast dispatch

Process stability

Build-to-print ceramic parts produced from drawings or samples, aligned to operating conditions.

Prototype → series

Tolerance control

Surface finishing

1) Technical review

Confirm operating conditions, geometry risks, tolerance stack-up, and a fit-for-service material system.

2) Prototype or first article

Validate dimensions, surface integrity, and assembly interfaces before scaling production.

3) Production + inspection

Run controlled batches with inspection checkpoints to maintain part-to-part consistency across orders.

ADCERAX Engineering Workflow

ADCERAX's History

Years of Journey

ADCERAX® is the global export brand of HUNAN ATCERA CO., LTD.

Since 2010, HUNAN ATCERA has built integrated ceramic manufacturing capabilities across alumina, zirconia, silicon carbide, silicon nitride, and specialty ceramic systems.

History

Alumina & Zirconia Workshop Placed into Operation

Powder purification technology was developed, achieving alumina purity above 99.9% in compliance with GB/T 40396-2021.

High-toughness 3Y-TZP ceramic balls with fatigue strength exceeding 1200 MPa were produced and introduced into medical device supply chains.

2010

Domestic high-end ceramics broke through

SiC & Si₃N₄ Production Line Brought Online

Reaction-bonded and sintered silicon carbide production established. Silicon nitride components developed for high-frequency and high-temperature applications.

2018

Layout of third generation semiconductor key materials

AlN & BN Production Capability Expanded

Aluminum nitride substrates and boron nitride components added to product portfolio, serving semiconductor packaging and high-temperature tooling applications.

2022

Enter the Track of Wide Bandgap Semiconductor Packaging

ADCERAX Global Brand Launch

ADCERAX® established as the international export brand of HUNAN ATCERA CO., LTD., providing direct factory access to engineering teams worldwide.

2025

ADCERAX

Manufacturing Capability

Manufacturing capacity is defined by physical scale, technical depth, and process integration. The following indicators outline the production foundation supporting ADCERAX ceramic component manufacturing.

5,600 m²

3,100 m²

42 engineers

254 employees

3–30 days

Liling & Pingxiang,

China

Quality Assurance

ISO 9001 certified. Full inspection at every stage — from incoming material to final shipment.

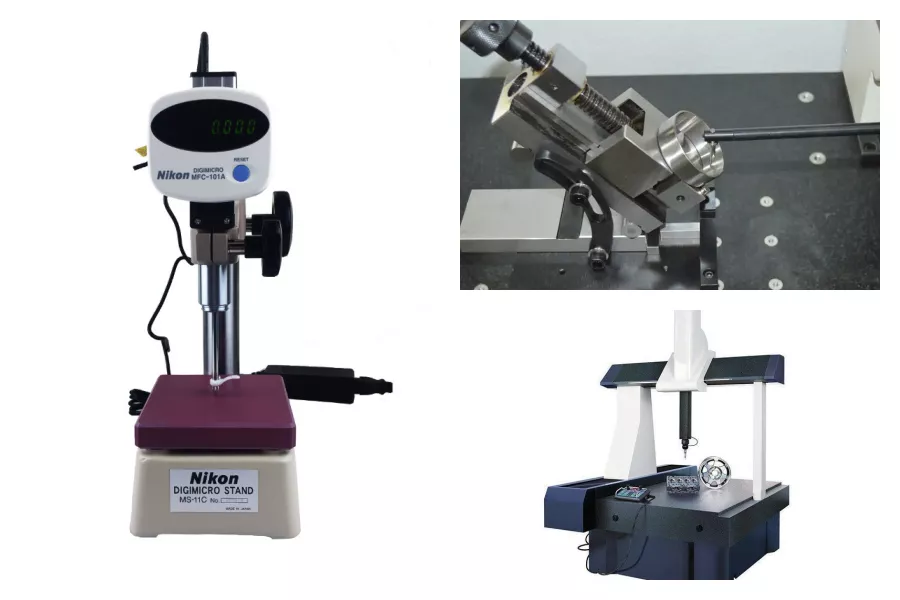

ADCERAX quality lab is equipped with CMM, 2D vision system, roughness tester, hardness tester, and density meter for complete dimensional and material verification.

Calibrated measurement ensures tolerance compliance at key features.

Finish and edge integrity are inspected after machining and cleaning.

Repeat orders are monitored for stability across production cycles.

Inspection results can be organized for procurement and quality review.

Advanced Ceramic Material Systems

Industries We Serve

ADCERAX components operate in demanding environments across:

ADCERAX®

Working Directly with ADCERAX Factory

Direct collaboration at the manufacturing level shortens feedback loops and improves control over process, quality, and delivery consistency.

- Challenge with Traders

Slow technical response

No visibility into production

Quality varies between orders

Middleman markup

Communication delays

- ADCERAX Advantage

Engineering team responds within 24 hours

Direct access to process and QC data

Same process, same team, every batch

Factory pricing, transparent costing

Single point of contact, faster decisions

team members

Creative Team

our team

Certifications & Compliance

The manufacturing operations are governed by standardized quality and compliance frameworks.

All certifications are issued to the legal manufacturing entity and apply consistently across ADCERAX® products.

- ISO 9001 Quality Management System

- SGS Testing & Certification

- CE Marking (European Conformity)

- RoHS Compliance

- CQC (China Quality Certification)

Our Offices

Liling Factory (Headquarters)

Building 108, Industrial Park, Liling City, Hunan Province, China

Focus: Alumina, Zirconia, Specialty Ceramics

Pingxiang Factory

No 19. Changchuncun, Xiabuzhen, Xiangdong District, Pingxiang, Jiangxi, China

Focus: Silicon Carbide, Silicon Nitride, High-Temperature Ceramics

ADCERAX Office

No. 9 Yuhe Road, Guitang Street, Changsha City, Hunan Province, China

Send a PDF drawing + service conditions for a clean feasibility review.