ADCERAX offers a wide range of alumina ceramic components designed for high-performance industrial applications. Known for their exceptional hardness, electrical insulation, and corrosion resistance, our alumina ceramics are available in various shapes and purities, including 96%, 99%, 99.5%, and 99.7% Al₂O₃.

Whether you need standard parts or custom alumina ceramic components, we provide precision machining, fast delivery, and expert engineering support.

✅Flexible Customization & Rapid Prototyping

✅Precision Machining Services

✅Expert Engineering Support

✅24-Hour Dispatch Guarantee

Alumina ceramic, also known as aluminum oxide ceramic (Al₂O₃), is a high-performance and durable technical ceramic widely used in industrial applications. It is valued for its exceptional hardness (Mohs ≥ 9), high dielectric strength (10–12 kV/mm), excellent thermal conductivity (18–30 W/m·K), and outstanding corrosion and wear resistance. Available in purities ranging from 95% to 99.9%, alumina ceramics are ideal for use in electronics, chemical processing, high-temperature furnaces, and precision machinery.

Superior wear resistance for demanding applications

Operates reliably up to 1750°C

Outstanding dielectric properties

Inert to acids, alkalis, and corrosive media

Alumina ceramic offers high density, purity, and surface finish, making it ideal for applications requiring wear resistance, dimensional accuracy, and thermal stability.

| Property | Typical Value/Range | Description |

|---|---|---|

| Density | 3.6-3.98 g/cm³ | Higher purity results in higher density (≥3.97 g/cm³ for 99% Al2O3). |

| Purity | 96%-99.9% Al2O3 | Industrial grade typically 96%-99.5%, high-purity grade up to 99.9%. |

| Color | White or off-white | Higher purity appears whiter; impurities may cause a light yellow tint. |

| Surface Roughness | Ra 0.1-0.6 µm | Can achieve mirror finish (Ra <0.05 µm) after polishing. |

Material grades per IEC 60672-3: 96% (Type C-786), 99% (Type C-795), 99.7% (Type C-799). Compliant with ASTM D2442.

| Parameter | Parameter Range | Description | Application |

|---|---|---|---|

| Melting Point (°C) | 2050 – 2070 | High melting point ensures excellent high-temperature stability. | Aerospace components, high-temperature furnace parts. |

| Max Operating Temp (°C) | 1600 -1800 | Allows for operation in extremely high-temperature environments. | Metallurgical industry, ceramic-based heat exchangers. |

| Thermal Expansion Coefficient (x 10-6/K) | 7.6 | Relatively low thermal expansion coefficient provides good thermal shock resistance. | Thermal protection systems in rockets, electronic substrates. |

| Thermal Conductivity (W/(m·K)) | 20 – 30 | High thermal conductivity enables efficient heat dissipation. | Power semiconductor devices, LED heat sinks. |

| Property | Value/Range | Description | Application |

|---|---|---|---|

| Dielectric Strength | 15 – 22 kV/mm | High dielectric strength ensures reliable electrical insulation in high-voltage applications. | High-voltage power transmission components. |

| Volume Resistivity | >10¹⁴ | Extremely high volume resistivity provides excellent electrical insulation performance. | Electronic circuit insulators. |

| Dielectric Constant | 9.2-9.8 | Moderate dielectric constant is suitable for applications requiring stable capacitance in electronic devices. | Capacitors in electronic circuits. |

| Loss Tangent | 10-4 – 10-3 | Low loss tangent indicates minimal energy loss in alternating-current applications, improving efficiency. | RF and microwave components. |

| Property | Typical Value/Range | Description |

|---|---|---|

| Acid Resistance | Resistant to strong acids (except HF and hot concentrated H₂SO₄) | Stable against most inorganic acids; hydrofluoric acid can corrode the surface. |

| Alkali Resistance | Resistant to weak alkalis, not resistant to strong alkalis | Strong alkalis (e.g., molten NaOH) cause slow corrosion. |

| Oxidation Resistance | Excellent | Resistant to oxidation at high temperatures, does not react with O₂. |

| Solvent Resistance | Fully inert | Insoluble in organic solvents (e.g., alcohols, hydrocarbons). |

| Property | Typical Value/Range | Description |

|---|---|---|

| MohS Hardness | 8.9-9.1 | Second only to diamond and silicon carbide, excellent wear resistance. |

| Flexural Strength | 200-420 MPa | 99.9% Al₂O₃ can exceed 420 MPa. |

| Compressive Strength | 2000-2500 MPa | the higher the purity of alumina ceramics, the greater its compressive strength. |

| Fracture Toughness (KIC) | 7-10 MPa·m¹/² | Brittle material, but toughness can be improved with additives (e.g., ZrO₂). |

| Property | 96% Al₂O₃ | 99% Al₂O₃ | 99.7% Al₂O₃ |

|---|---|---|---|

| Density (g/cm³) | 3.65-3.8 | 3.8-3.9 | ≥3.93 |

| MohS Hardness | 8.9 | 9.0 | 9.1 |

| Flexural Strength (MPa) | 200-250 | 350-400 | 380-420 |

| Thermal Conductivity (W/(m·K)) | 22 | 24 | 29 |

| Volume Resistivity (Ω·cm) | >10¹⁴ | >10¹⁴ | >10¹⁴ |

We supply a comprehensive range of alumina ceramic products and custom parts wholesale, from standard industrial components to precision-engineered solutions tailored to your specifications. Our product line includes various purity grades (95%–99.8%) covering substrates, wear-resistant parts, insulators, and structural components.

We maintain a ready stock of standard alumina ceramic products, ensuring 24-hour dispatch for urgent requirements, enabling you to minimize downtime and maintain operational continuity.

Alumina ceramic components are crucial in extending the lifespan and enhancing the performance of industrial machinery.

The alumina ceramic seals provided by ADCERAX have been running for over 18 months without any signs of leakage or wear. This completely solved our pump sealing issues, extending the maintenance cycle by 6 times and significantly improving production efficiency.

— Production Manager, German Chemical Group

Exceptional electrical insulation properties make alumina ideal for critical electronic applications.

ADCERAX’s precision alumina ceramic components are critical to our next-generation wafer manufacturing equipment. Their ultra-high purity and machining accuracy have helped us achieve more stable process control and higher yields, making them true technology partners.— R&D Director, US Semiconductor Equipment Company

Remarkable thermal stability and resistance to thermal shock for extreme heat environments.

The ADCERAX alumina labware has been a game-changer for our high-temperature research. We no longer worry about material contamination or premature failure, allowing us to focus on groundbreaking experiments with reliable and reproducible results.— Lead Researcher, Materials Science Department, US Research University

Chemical inertness and corrosion resistance for aggressive chemical environments.

The nozzle wear problem in our water treatment system has always plagued us. ADCERAX’s alumina ceramic nozzles have performed exceptionally well, with wear resistance several times that of traditional metal nozzles, greatly reducing our operating costs and maintenance time. — Operations Director, Canadian Environmental Water Treatment Company

Biocompatible and precision components for specialized applications.

ADCERAX’s alumina ceramic valves are key to our diagnostic equipment’s ability to deliver high-precision and reliable test results. Their durability and bio-inertness give us confidence in the long-term performance of our products.— Product Development Manager, UK Medical Device Company

Components for renewable energy and advanced technology applications.

Since adopting ADCERAX’s alumina ceramic components, the wear problem in our battery production line has been fundamentally resolved. Component life has extended by more than 3 times, and product quality stability has significantly improved, saving us substantial replacement and downtime costs.”— Process Engineer, Japanese New Energy Enterprise

ADCERAX is a professional China alumina ceramics manufacturer that offers high-performance components with tight tolerances (±0.001mm) and custom geometries. Using advanced forming methods and CNC machining, we deliver precision-engineered solutions for electronics, chemical, and high-temperature applications.

This table highlights our core technical strengths, including material options, tight tolerances, and advanced manufacturing methods. We offer tailored solutions to meet diverse industrial requirements.

| Technical Capabilities Overview | |

|---|---|

| Material Grades | 96%, 99%, 99.5%, 99.7% Al₂O₃ – high purity for demanding applications |

| Tolerances | Up to ±0.001mm – suitable for precision assemblies |

| Forming Methods | Dry pressing, isostatic pressing, extrusion, casting, injection molding |

| Processing | CNC machining, fine grinding, polishing |

| Customization | Drawings, CAD files, or samples accepted for custom parts |

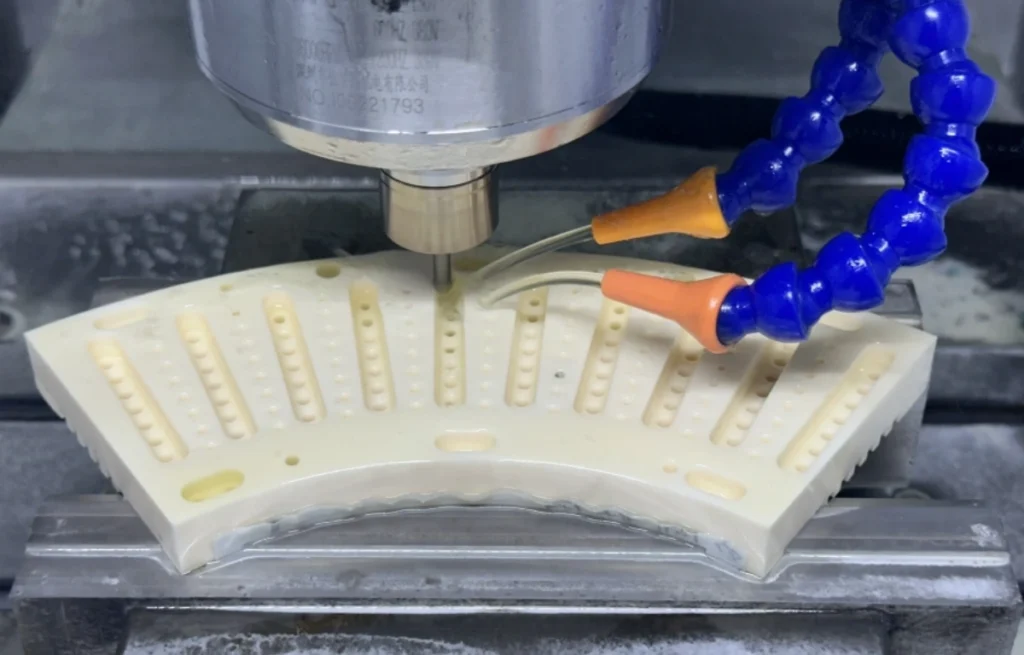

State-of-the-art CNC equipment delivers exceptional precision for complex geometries and ultra-tight tolerances, ensuring perfect fit and function.

Advanced sintering furnaces with precise temperature control ensure optimal density and superior material properties for demanding applications.

Professional polishing and surface treatment services deliver exceptional surface quality and performance characteristics for critical applications.

Let our advanced capabilities bring your ceramic component vision to life.

ADCERAX provides custom alumina ceramic components, including tubes, rods, plates, and complex parts, all manufactured with precision machining and tight tolerances up to ±0.01 mm. Our alumina ceramics are engineered for demanding environments, offering excellent electrical insulation, thermal stability, and mechanical strength. We support small-batch prototyping, mass production, and global delivery with ISO-compliant quality control.

±0.01mm

Precision Tolerance

→”Meeting aerospace & semiconductor standards”

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Choosing the right advanced ceramic supplier is crucial for the success of your industrial projects. ADCERAX stands out as a reliable and competitive partner.

Direct manufacturer eliminating intermediaries for cost-effective solutions without compromising quality.

20+ years of B2B experience providing unparalleled technical support and collaborative design.

Agile manufacturing for small-batch customization and rapid prototyping capabilities.

Stringent quality measures from raw material inspection to final product testing.

24-hour response guarantee with dedicated support for global clientele.

Trusted by global customers for advanced ceramic materials and precision components.

Yes, alumina is a type of ceramic.

Alumina ceramic is a kind of advanced ceramic material. It is made from alumina (Al₂O₃) as the main raw material. Alumina ceramics have many excellent properties, such as high hardness, high melting point, good chemical stability, high electrical resistivity, and low dielectric loss. They are widely used in various fields, including electronics, machinery, aerospace, and medical devices.

Yes. Alumina ceramic is extremely durable due to its high hardness (Mohs ≥ 9), excellent wear resistance, and chemical inertness. It performs reliably in harsh environments, including high temperatures and corrosive conditions.

We offer alumina ceramics in various purities, including 95%, 99%, 99.5%, 99.7%, and 99.8%. Higher purity grades provide better electrical insulation, thermal conductivity, and mechanical strength.

Several shaping methods can be employed in the fabrication of alumina ceramics, which are typically derived from bauxite. These methods include injection molding,isostatic pressing, die pressing, slip casting, diamond machining, and extrusion.

| Method | Description | Applications |

|---|---|---|

| Injection Molding | Ceramic powder and binder injected into a mold. | Complex shapes, high volume, small intricate parts. |

| Isostatic Pressing | Powder compacted in a flexible mold under uniform pressure. | Uniform density, complex shapes, high strength parts. |

| Die Pressing | Powder compacted in a rigid die. | Simpler shapes, economical, tiles, plates. |

| Slip Casting | Ceramic slip poured into a porous mold. | Hollow shapes, sanitaryware, vases. |

| Diamond Machining | Material removed from pre-sintered ceramic using diamond tools. | High-precision, tight tolerances, finishing process. |

| Extrusion | Plastic ceramic mass forced through a die. | Long shapes, constant cross-section, tubes, rods. |

Cutting aluminum oxide ceramic involves several methods, each suited to different applications:

Cleaning aluminum oxide ceramic is generally straightforward due to its chemical resistance. The best method depends on the type of soiling:

Important Considerations:

| Property | Zirconia (ZrO2) | Alumina (Al2O3) |

| Mohs Hardness | 9 | 9.1 |

| Fracture Toughness | Very High (7-10 MPa·m¹/²) | Moderate (3-5 MPa·m¹/²) |

| Flexural Strength | High (800-1500 MPa) | Moderate (200-300 MPa) |

| Compressive Strength | Very High (2000-2500 MPa) | High (2000-2500 MPa) |

| Young's Modulus | Moderate (200-220 GPa) | High (300-320 GPa) |

| Thermal Conductivity | Low (2-3 W/mK) | Moderate (20-30 W/mK) |

| Thermal Expansion | Moderate (10-11 x 10⁻⁶ /°C) | Moderate (7-8 x 10⁻⁶ /°C) |

| Max Operating Temp | High (Up to 2100°C depending on stabilize) | High (Up to 1750°C) |

| Chemical Resistance | Excellent (resistant to many acids and alkalis) | Excellent (resistant to many acids and alkalis) |

| Wear Resistance | Excellent | Excellent |

| Biocompatibility | Excellent (used in medical implants) | Good |

| Cost | Higher | Lower |

Zirconia:Exceptional toughness, high strength, good wear resistance, excellent biocompatibility.But lower thermal conductivity, higher cost.

Alumina:High hardness, good wear resistance, good chemical resistance, lower cost.But lower toughness compared to zirconia, moderate thermal conductivity.

If you are not sure which material to choose for your product, please contact us to recommend for you.

Working with alumina (Al2O3) means shaping an advanced ceramic that's known for being extremely hard but also brittle. Its great properties – like hardness, wear resistance, high-temperature stability, electrical insulation, and chemical resistance – make it crucial for many demanding industrial applications. However, that same hardness and brittleness make it tough to machine using regular methods.

The Main Challenges

Common Machining Methods

Because of these challenges, specialized techniques are needed:

Absolutely. We provide precision machining services for alumina ceramics, including CNC grinding, cutting, and polishing. We support custom parts based on your drawings or samples, with tolerances up to ±0.001 mm.

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Ready to elevate your industrial applications with high-performance alumina ceramics? Whether you need standard products or custom-engineered solutions, ADCERAX is your trusted partner.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours

WhatsApp us

The more details you provide, the faster we can respond.

*We respond within 24 hours. All inquiries are confidential.

The more details you provide, the faster we can quote.

*We respond within 24 hours. All inquiries are confidential.