Engineering teams face increasing demand for materials that combine durability, precision, and cost efficiency.

The alumina ceramic manufacturing process follows four essential stages—raw material preparation, forming, sintering, and finishing—each influencing microstructure evolution, shrinkage behavior, and final mechanical performance.

Every stage carries technical decisions that determine cost, strength, reliability, and yield rate.

Defining the Alumina Ceramic Manufacturing Process

The manufacturing of alumina ceramics has evolved into a technically disciplined workflow.

It includes a series of controlled stages that ensure consistent density, strength, Weibull modulus, and thermal stability.

The alumina ceramic manufacturing process is a sequence of powder preparation, forming, sintering, and finishing, producing parts with high strength, structural uniformity, and manufacturing repeatability.

Each stage reflects advances in powder science, process modeling, forming mechanics, and precision machining.

Raw Material Preparation in Alumina Ceramic Manufacturing

Raw material preparation establishes the foundation for reliable ceramic performance.

In powder-based ceramics, every downstream property—shrinkage rate, densification rate, porosity, grain growth, and mechanical reliability—depends on powder characteristics.

Raw material preparation typically involves:

- purification

- particle size control

- additive formulation

- powder morphology optimization

- specific surface area (BET) adjustment

- agglomeration reduction

Modern production requires more controlled methods than earlier practices, especially for high-purity grades ≥99.8% alumina.

Powder Purification and Particle Size Control

Purity levels directly influence sintering efficiency and microstructural evolution.

Many industrial processes target ≥99.8% Al₂O₃, minimizing silica, sodium oxide, and alkali impurities to avoid abnormal grain growth.

Key powder parameters include:

- particle size distribution (PSD)

- specific surface area (BET)

- particle morphology

- agglomeration index

- moisture content

- flowability and rheology

Uniform powders minimize differential shrinkage and reduce internal stresses during sintering.

By controlling particle sizes between 0.2–0.8 μm and achieving a narrow PSD, final parts reach flexural strengths above 350 MPa, with improved density gradients and lower defect propagation.

Results:

- stable density

- enhanced strength

- higher Weibull modulus

- lower defect rates

Advanced Milling and Homogenization Techniques

Milling disperses alumina particles and breaks down soft agglomerates.

Attrition mills and planetary mills provide high-energy input, optimizing:

- packing density

- neck formation potential during sintering

- slurry rheology for tape casting or injection molding

Homogenization ensures compositional uniformity, directly supporting:

- predictable shrinkage behavior

- microstructure refinement

- more uniform densification across the part

Optimized milling yields stronger microstructures, lower porosity, and high sintering repeatability.

Additive Formulation for Improved Green Strength

Binders, dispersants, plasticizers, and defoamers play essential roles in green body behavior.

Common additives such as polyvinyl alcohol (PVA) improve cohesion in pressed or molded compacts.

Dispersants stabilize slurry viscosity, ensuring uniform casting thickness and reducing lamination defects.

Benefits:

- higher forming yields

- 30% fewer drying cracks

- reduced pore entrapment

- better green density uniformity

These directly influence tool life, machining effort, and final part reliability.

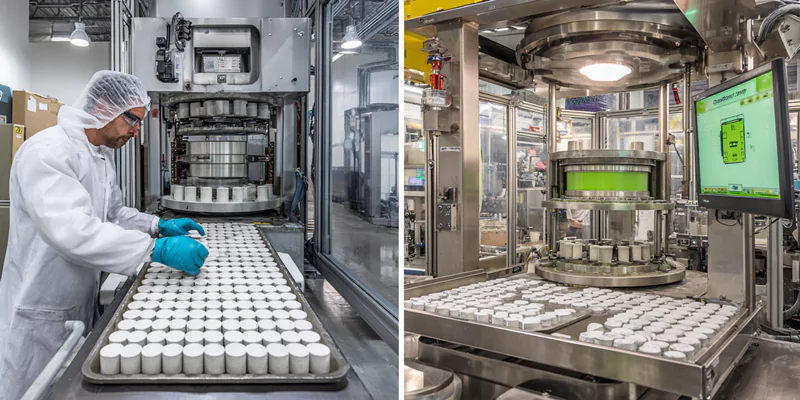

Forming Techniques for Alumina Ceramic Components

Forming determines geometry, density distribution, and green body integrity.

Engineering teams must align forming methods with tolerances, defect risk, mold cost, and batch size economics.

Forming techniques include pressing, isostatic pressing, injection molding, and tape casting—each suited for different tolerances, geometries, and density requirements.

Selecting the right method balances performance, yield rate, and total manufacturing cost.

Dry Pressing and Isostatic Pressing Methods

Dry pressing compacts alumina powders into simple shapes, while cold isostatic pressing (CIP) applies fluid pressure to achieve uniform density.

Typical engineering considerations:

- green density uniformity

- density gradient minimization

- risk of lamination defects

- demolding cracks

- binder burnout behavior

Isostatic pressing often yields:

- 5–10% higher sintered strength

- lower warpage

- reduced differential shrinkage

Pressing offers efficient high-volume production, dimensional stability, and lower tooling cost compared to molding.

Injection Molding for Complex Geometries

Injection molding enables near-net-shape fabrication of complex components.

Feedstocks combine alumina with polymers, requiring:

- precise binder burnout schedules

- control of differential shrinkage

- modulated debinding rates

Advantages:

- lower machining requirement

- excellent repeatability

- tight tolerances: ±0.01–0.03 mm

Comparison:

| Method | Typical Tolerance (mm) | Efficiency | Best Application |

|---|---|---|---|

| Dry Pressing | ±0.05–0.10 | High | Simple bulk components |

| Isostatic Pressing | ±0.02–0.05 | Medium | High-uniformity parts |

| Injection Molding | ±0.01–0.03 | Moderate | Complex small geometries |

| Tape Casting | ±0.005–0.010 | High | Thin electronic substrates |

Tape Casting for Thin Substrates

Tape casting spreads slurry into thin films for electronic substrates and multilayer ceramics.

Critical engineering parameters include:

- slurry viscosity / rheology

- casting speed

- binder burnout profile

- drying rate

- warpage control

Tape casting ensures:

- stable dielectric properties

- high dimensional precision

- low defect rates

- scalable thin substrate production

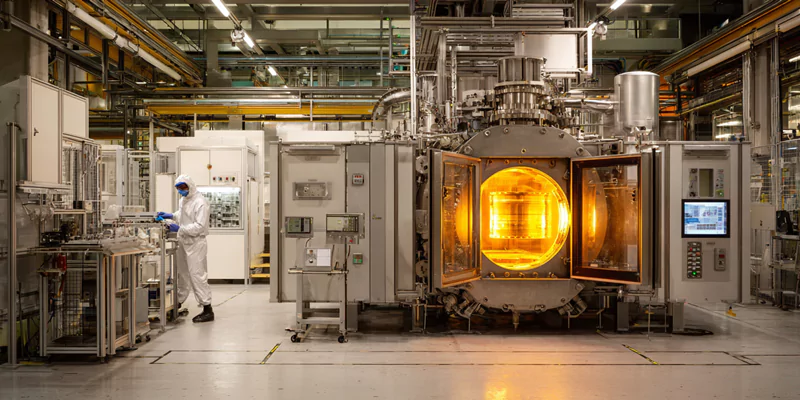

Sintering Processes in Alumina Ceramic Manufacturing

Sintering transforms green compacts into dense ceramics.

The microstructural evolution—grain growth, pore elimination, neck formation, and grain boundary diffusion—governs strength and long-term performance.

Temperature schedules and atmosphere control directly influence:

- densification rate

- final porosity

- thermal stress

- Weibull modulus

- yield consistency

Conventional Sintering and Temperature Profiles

Conventional sintering at 1550–1650 °C drives densification through:

- surface diffusion

- grain boundary diffusion

- lattice diffusion

- neck formation and growth

Key engineering needs:

- slow heating to reduce cracking

- uniform temperature distribution

- controlled cooling to minimize thermal gradients

Optimized processes achieve:

- reduced porosity

- stable grain size

- 350 MPa flexural strength

- predictable shrinkage curves

Hot Isostatic Pressing (HIP) Enhancements

HIP applies heat and pressure using argon gas up to 200 MPa, promoting full pore closure.

Benefits:

- >99.9% density

- 20% higher mechanical strength

- higher fracture toughness

- improved fatigue resistance

Comparison:

| Technique | Density (%) | Energy Demand | Mechanical Strength (MPa) |

|---|---|---|---|

| Conventional | 96–98 | High | 300–350 |

| HIP | >99.9 | Very High | 360–420 |

| Microwave | 95–97 | Low | 280–340 |

Microwave Sintering for Energy Efficiency

Microwave sintering couples energy directly to ceramic particles, enabling:

- 30–40% shorter sintering cycles

- 20–30% energy savings

- more uniform internal heating

Benefits:

- reduced processing times

- lower emissions

- improved economics for small batches

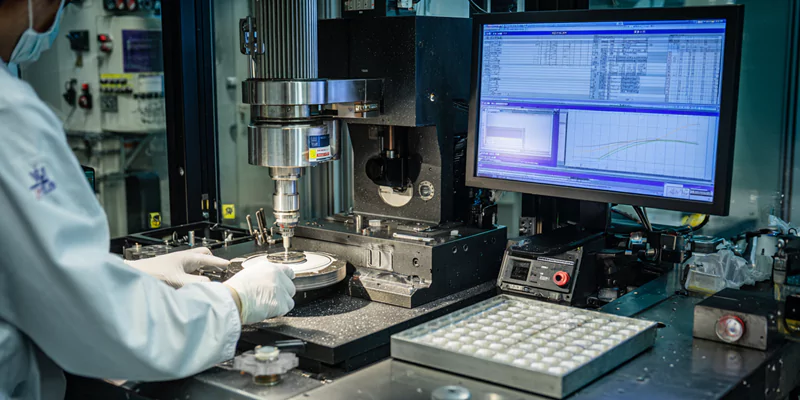

Finishing and Machining of Alumina Ceramic Parts

Finishing defines functional surfaces, microfeatures, and interface tolerances.

Because alumina is extremely hard and brittle, machining requires careful control of tool wear, material removal rate (MRR), coolant flow, and thermal stress.

Methods include grinding, polishing, laser machining, and micro-feature texturing.

Diamond Grinding for Dimensional Precision

Diamond grinding achieves tolerances as fine as ±0.01 mm.

Critical parameters:

- diamond wheel grit size

- feed rate & spindle speed

- coolant selection

- thermal cracking prevention

- subsurface damage minimization

Optimized grinding ensures:

- tight dimensional control

- extended service life

- reduced micro-chipping

- lower rejection rates

Laser Processing for Micro-Features

Laser machining enables microchannels and small apertures without mechanical stress.

Advantages:

- 1–5 µm accuracy

- no tool wear

- ideal for microfluidic components and biomedical prototypes

Comparison:

| Technique | Accuracy (µm) | Suitable Feature Size | Material Removal Rate |

|---|---|---|---|

| Diamond Grinding | 10–20 | Large areas | Moderate |

| Laser Processing | 1–5 | Microchannels | Low |

| Polishing | <1 | Surface smoothness | Very Low |

Surface Polishing and Defect Reduction

Polishing reduces surface roughness below Ra 0.02 μm and removes subsurface flaws that may act as crack initiation points.

Engineering benefits:

- higher optical clarity

- stress resistance

- improved fatigue life

- higher reliability in mechanical assemblies

Cost Drivers in Alumina Ceramic Manufacturing

To align manufacturing decisions with procurement goals, engineers must understand major cost contributors:

- tooling cost (molds, dies, jigs)

- cycle time (forming + sintering + machining)

- yield rate

- scrap ratio

- energy consumption

- machining effort and tool wear

- batch size effect / mold amortization

These factors strongly influence unit pricing, production scalability, and feasibility of small-batch customization.

Application Impact: Why Manufacturing Choices Matter

Manufacturing routes influence performance in real applications:

- High-voltage insulation components rely on high density and minimal porosity.

- Wear-resistant pump plungers and valve parts require fine-grained microstructures and precise machining.

- Analytical instrument components need tight tolerance and surface smoothness.

- Electronic substrates depend on controlled dielectric properties from uniform tape casting.

Choosing the correct route optimizes performance, cost, and lifespan across industries.

Conclusion

Each stage of the alumina ceramic manufacturing process shapes final product quality through powder engineering, forming mechanics, sintering science, and finishing technologies.

ADCERAX supports engineering teams with factory-direct alumina ceramics, high-purity options, custom machining (±0.02 mm), and small-batch prototyping to meet demanding industrial requirements.

FAQ

Q1: What mechanisms drive densification during alumina sintering?

Grain boundary diffusion, lattice diffusion, and neck formation dominate densification above 1200 °C.

Q2: How do particle size and PSD affect shrinkage?

Finer and narrower particle distributions provide higher green density and more predictable shrinkage curves.

Q3: What determines the final surface finish after grinding?

Diamond wheel grit size, coolant flow, and feed rate strongly influence subsurface damage and micro-chipping.

Q4: Why do HIPed alumina components achieve higher reliability?

HIP eliminates closed pores, increasing density and improving the Weibull modulus.

Q5: How do production costs scale with batch size?

Tooling amortization and yield rate improvements significantly reduce unit costs in medium-to-large batches.

References:

- Explore the benefits of Polyvinyl alcohol to understand its role in enhancing cohesion and improving product quality.

- Learn how injection molding enhances production efficiency and design flexibility.

- Discover tape casting principles for thin-film ceramics and electronics.

- Explore HIP technology to understand advanced densification and reliability improvements.