High Purity Alumina Ceramic for High-Temperature & Electrical Insulation Applications

High purity alumina ceramic with 99–99.9% Al₂O₃ purity is widely used for high-temperature insulation, wear resistance and corrosive operating conditions. ADCERAX supplies a full range of high purity alumina ceramic products, including tubes, rods, plates, crucibles, insulators and custom machined parts, serving equipment manufacturers and industrial users worldwide. As a factory-direct advanced ceramics manufacturer with engineering support and custom machining capability, we help you move from design to stable mass production with controlled cost and lead time.

👉Send your drawings or specifications today and let our engineers turn your requirements into reliable ceramic solutions.

What Is High Purity Alumina Ceramic?

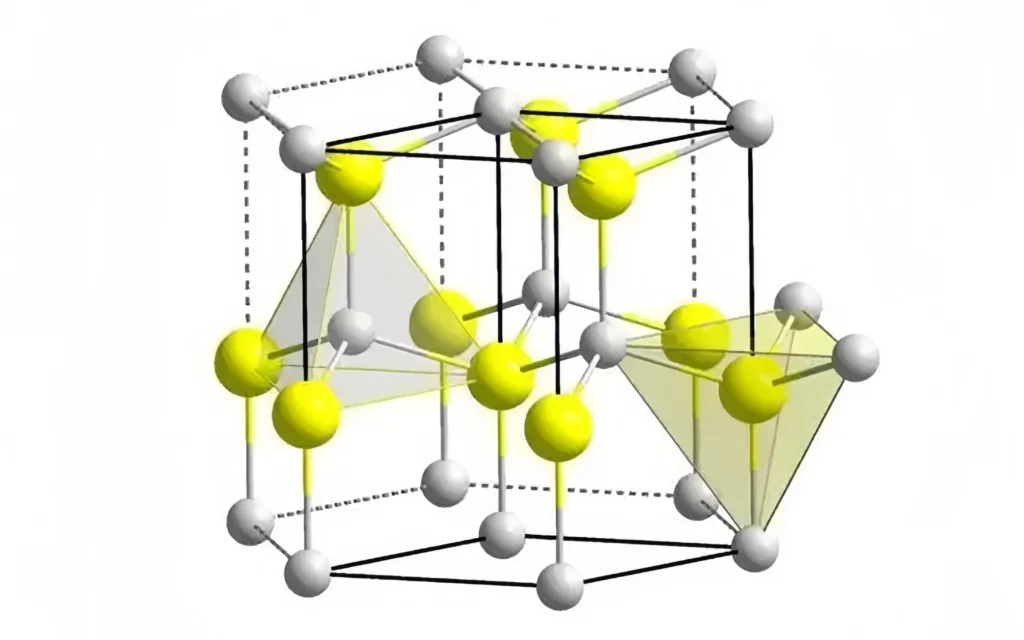

High purity alumina ceramic refers to technical ceramics made from aluminum oxide (Al₂O₃) with a purity level of 99–99.9%. Compared with standard alumina, this material grade delivers higher thermal stability, improved electrical insulation and superior chemical resistance for demanding industrial environments.

High Purity Alumina Ceramic Production Process

From high purity alumina powder to precision-finished ceramic components, ADCERAX controls every critical manufacturing step to ensure stable density, mechanical strength, dimensional accuracy, and consistent batch quality for high purity alumina ceramic parts.

High purity Al₂O₃ powders are selected and blended with controlled particle size for stable sintering and consistent material purity.

CIP or dry pressing is used to achieve uniform compaction, high green strength, and accurate pre-sintered dimensions.

Sintering at 1650–1750 °C delivers high density, controlled grain structure, and reliable thermal and dielectric performance.

Post-sintering CNC grinding and polishing ensure tight tolerances (±0.02 mm) and smooth functional surfaces.

Each batch is inspected for dimensions, density, strength, and microstructural consistency before release.

Each part is ultrasonically cleaned, vacuum-packed, and labeled with batch traceability for global shipment.

High Purity Al2O3 Ceramic Advantages

High purity alumina ceramic maintains structural stability and dielectric strength under continuous high-temperature operation and electrical load. It is widely used in furnace systems, heating equipment, and electrical insulation assemblies where long-term thermal and electrical reliability is required.

Although high purity alumina ceramic belongs to advanced ceramic materials, its high wear resistance, low failure rate, and long service life significantly reduce replacement frequency, unplanned downtime, and maintenance costs—resulting in a more predictable and controllable total operating cost.

With Al₂O₃ purity up to 99–99.9%, high purity alumina ceramic releases minimal impurities during thermal or chemical exposure. This helps maintain clean process conditions, reduces material contamination, and improves consistency in laboratory, analytical, and precision manufacturing environments.

High purity alumina ceramic can be manufactured as tubes, rods, plates, crucibles, insulators, and custom machined parts with controlled tolerances and surface finishes. This allows engineers to implement complex designs for furnaces, electrical systems, fluid handling equipment, and specialized industrial assemblies.

High Purity Alumina (Al2O3) Ceramic Properties

High purity alumina (Al₂O₃) ceramic provides excellent thermal stability, high electrical insulation, and strong mechanical strength. Its low impurity level ensures stable dielectric performance, low porosity, and reliable resistance to chemical and plasma corrosion under high-temperature and vacuum conditions.

High Purity Aluminum oxide Ceramic– Technical Sheet

| Performance Parameter | Standard Alumina Ceramic | High Purity Alumina Ceramic | Ultra High Purity Alumina Ceramic |

|---|---|---|---|

| Al₂O₃ Content (%) | 92–96% | 99–99.9% | ≥99.99% |

| Bulk Density (g/cm³) | 3.6–3.75 | 3.85–3.92 | 3.95–3.99 |

| Porosity | Relatively High | Extremely Low | Near Zero |

| Flexural Strength (MPa) | 250–320 | 350–420 | 450–600 |

| Vickers Hardness (HV) | 1200–1400 | 1600–1800 | 1800–2000+ |

| Dielectric Strength (kV/mm) | 10–12 | 15–18 | 20–25 |

| Volume Resistivity (Ω·cm) | 10¹² | 10¹⁴ | 10¹⁵–10¹⁶ |

| Thermal Conductivity (W/m·K) | 18–22 | 25–30 | 30–35 |

| Maximum Continuous Working Temperature (°C) | 1400–1500 | 1650–1700 | 1750–1800 |

| Plasma Corrosion Resistance | General | Excellent | Outstanding |

| Dimensional Stability | General | Very Good | Extremely High |

This chart displays the typical properties of alumina ceramic (Al2O3) materials used in our standard products. Please note: Customized parts may have adjusted characteristics depending on production methods, with specific parameters determined by the stabilizer type and formula chosen for your application.

Key Properties of High Purity Alumina Ceramic

High purity alumina remains stable under long-term high-temperature conditions, making it suitable for furnaces, heaters, and thermal processing systems.

Its high hardness and strength provide strong resistance to abrasion, impact, and mechanical fatigue in continuous operation.

It resists acids, alkalis, molten metals, and aggressive process gases, ensuring reliable performance in harsh chemical environments.

The dense microstructure minimizes particle generation and contamination, supporting clean use in electronic and vacuum applications.

High dielectric strength and volume resistivity ensure stable insulation in high-voltage, high-frequency, and plasma-related systems.

It maintains dimensional accuracy under repeated thermal cycling, supporting precision components and tight tolerance assemblies.

🔥 Built for extreme heat. Trusted for stable output.

High purity alumina parts for consistent high-temperature performance, long-term process stability, and dependable production results.👉 Tell us your needs for a custom high purity Al2O3 ceramic design.

High Purity Alumina Ceramic Applications

High purity alumina ceramic is widely used in high-temperature, electrical insulation, and chemically demanding environments, including industrial furnaces, thermal systems, electrical assemblies, and laboratory equipment, where stable thermal, dielectric, and chemical performance is required.

High-Temperature Processing & Thermal Equipment

🔹Advantages

- High thermal stability supports continuous operation at extreme temperatures

- Low impurity content reduces contamination during melting and heat treatment

- Excellent chemical resistance ensures reliable performance in aggressive thermal environments

- Long service life helps reduce replacement frequency and maintenance cost

Electrical Insulation & High-Voltage Systems

🔹Advantages

- High dielectric strength supports stable operation under high voltage

- Excellent electrical insulation prevents leakage and breakdown

- Strong thermal resistance ensures performance under combined heat and voltage

- Long-term dimensional stability improves system reliability and safety

Semiconductor, Vacuum & Plasma Systems

🔹Advantages:

- Low impurity content minimizes particle generation and process contamination

- High dielectric strength ensures stable performance in plasma and RF environments

- Excellent thermal and chemical stability supports prolonged high-energy exposure

- Long service life helps reduce downtime and replacement frequency

Laboratory & Materials Research Equipment

🔹Advantages:

- High purity ensures stable and repeatable experimental results

- Excellent resistance to thermal shock and reactive atmospheres

- Supports custom geometries for prototyping and small-batch research

- High dimensional stability improves precision testing reliability

customized high purity alumina ceramic Wholesaler

We specialize in custom high purity alumina (Al₂O₃) ceramic parts based on customer drawings, samples, or application requirements. Dimensions, wall thickness, stepped profiles, and complex geometries can be precisely tailored to specific operating conditions. Custom high purity alumina components typically require 3–9 weeks depending on design complexity, purity grade, and finishing specifications.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

china high purity alumina ceramic manufacturer

ADCERAX is a China high purity alumina (Al₂O₃) ceramic manufacturer delivering consistent quality, stable lead times, and responsive technical support for precision ceramic components. Our factory-direct supply model helps buyers improve supply reliability, control procurement cost, and maintain dependable performance in demanding operating conditions.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

ADCERAX provides integrated manufacturing for high purity alumina ceramic components, delivering stable quality, controlled lead times, and reliable engineering support. As a China high purity alumina ceramic manufacturer, we help industrial users obtain dependable Al₂O₃ parts for high-temperature, electrical insulation, vacuum, and precision processing applications.

-

Precision Machining & Dimensional Consistency:

High purity alumina ceramic parts are machined with accurate dimensions, consistent wall thickness, and clean surface finishes to meet the requirements of thermal equipment, electrical insulation systems, and precision assemblies. Our capabilities support customers seeking engineered high purity alumina components with tight tolerances. -

Batch Stability & Performance Control:

Each production batch is strictly inspected for purity, density accuracy, and dimensional stability to ensure predictable performance under high-temperature and high-voltage conditions. With strict process control, we provide consistent and repeatable performance across long-term production. -

Customization & Engineering Support:

We offer drawing-based customization for complex shapes, stepped profiles, micro structures, and thin-wall sections. With strong experience as a high purity alumina ceramic manufacturer in China, our engineering team supports application matching for furnaces, electrical systems, vacuum equipment, semiconductor tools, and laboratory environments.

ADCERAX manufactures high purity alumina (Al₂O₃) ceramics with controlled formulation, precision machining, and strict dimensional consistency. Our components provide reliable electrical insulation, chemical resistance, and stable performance in high-temperature and vacuum environments for demanding industrial use.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Item | Typical Value / Description | ||

| Purity & Material Stability | High purity Al₂O₃ ensures excellent chemical inertness, low contamination risk, and stable performance in high-temperature and vacuum environments. | ||

| Precision Geometry & Surface Quality | Tight tolerances (±0.05–0.15 mm) and clean surface finishes support accurate assembly, reliable sealing, and precise component alignment. | ||

| Customization Capability | Supports complex shapes, thin-wall structures, stepped profiles, and deep cavities for precision ceramic component designs. | ||

| High-Temperature & Vacuum Reliability | High purity alumina maintains dimensional stability under extreme heat, thermal cycling, and vacuum conditions, reducing failure risk. | ||

| Consistent Batch Quality | Every batch is verified for density uniformity and thermal performance to ensure predictable and repeatable results in critical applications. | ||

FAQs About High Purity Aluminum Oxide Ceramic

Standard alumina (92–96%) is mainly used for structural wear parts, while high purity alumina (≥99%) offers higher dielectric strength, lower porosity, better thermal stability, and cleaner performance for electronic and high-temperature applications.

Even trace impurities can significantly affect electrical insulation, plasma stability, and chemical resistance, leading to contamination, leakage currents, or premature failure in critical systems.

High purity alumina typically supports continuous operation at 1650–1700°C, with short-term exposure up to 1800°C, depending on part geometry and thermal load conditions.

Yes. Its low outgassing rate, dense microstructure, and excellent chemical stability make it highly suitable for high and ultra-high vacuum systems.

Yes. High purity alumina is widely used in plasma chambers, RF insulation parts, gas distribution components, and vacuum fixtures due to its low contamination risk and strong dielectric performance.

High purity alumina offers good thermal shock resistance, especially in thin-wall or engineered geometries. However, controlled heating and cooling rates are still recommended for long service life.

Surfaces can be supplied in as-fired, fine-ground, polished, or mirror-finish conditions, depending on application needs such as sealing, cleanliness, or optical interfaces.

High purity alumina supports tubes, rods, crucibles, plates, discs, rings, stepped profiles, thin-wall structures, and complex cavities based on drawings.

The main cost drivers include purity grade (99.5% vs 99.9%+), part size, shape complexity, machining tolerance, surface finish, and order quantity. Higher purity and tighter tolerances significantly increase production cost.

High purity alumina parts are typically 1.8–3.5× more expensive than 95% alumina, depending on purity level, machining difficulty, and inspection requirements.

Yes. Small-batch prototyping and pilot orders are supported, especially for R&D, laboratory validation, and pre-production testing.

High purity alumina emphasizes thermal stability, electrical insulation, and chemical resistance, while zirconia focuses on fracture toughness and silicon nitride on mechanical strength and thermal shock resistance.

| Property / Feature | High Purity Alumina (Al₂O₃ ≥99–99.9%) | Zirconia (ZrO₂) | Silicon Nitride (Si₃N₄) |

|---|---|---|---|

| Primary Advantage | Thermal stability, electrical insulation, chemical resistance | High fracture toughness | High mechanical strength & thermal shock resistance |

| Maximum Working Temperature | 1600–1700 °C | 900–1200 °C | 1200–1400 °C |

| Electrical Insulation | Excellent (high dielectric strength) | Good | Poor to moderate |

| Thermal Shock Resistance | Moderate | Moderate | Excellent |

| Hardness & Wear Resistance | High | Very high | High |

| Fracture Toughness | Medium | Very high | High |

| Chemical Resistance | Excellent to acids & alkalis | Very good | Good (limited acid resistance) |

| Density | Medium | High (heaviest) | Low (lightweight) |

| Typical Applications | Furnace parts, insulators, crucibles, lab equipment, wear parts | Medical, precision bearings, cutting tools | Turbochargers, bearings, thermal shock parts |

| Machinability After Sintering | Good (with diamond tools) | Difficult | Difficult |

| Typical Cost Level | Medium | High | High |

| Best Selection When | High temperature, electrical insulation, clean process required | High impact resistance and toughness needed | High load + rapid temperature change required |

In most industrial heating, insulation, and clean-process environments, high purity alumina offers the best balance between performance, stability, and total cost.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours