Aluminum Nitride (AlN) Substrates for Power Electronics, LED and RF Packaging

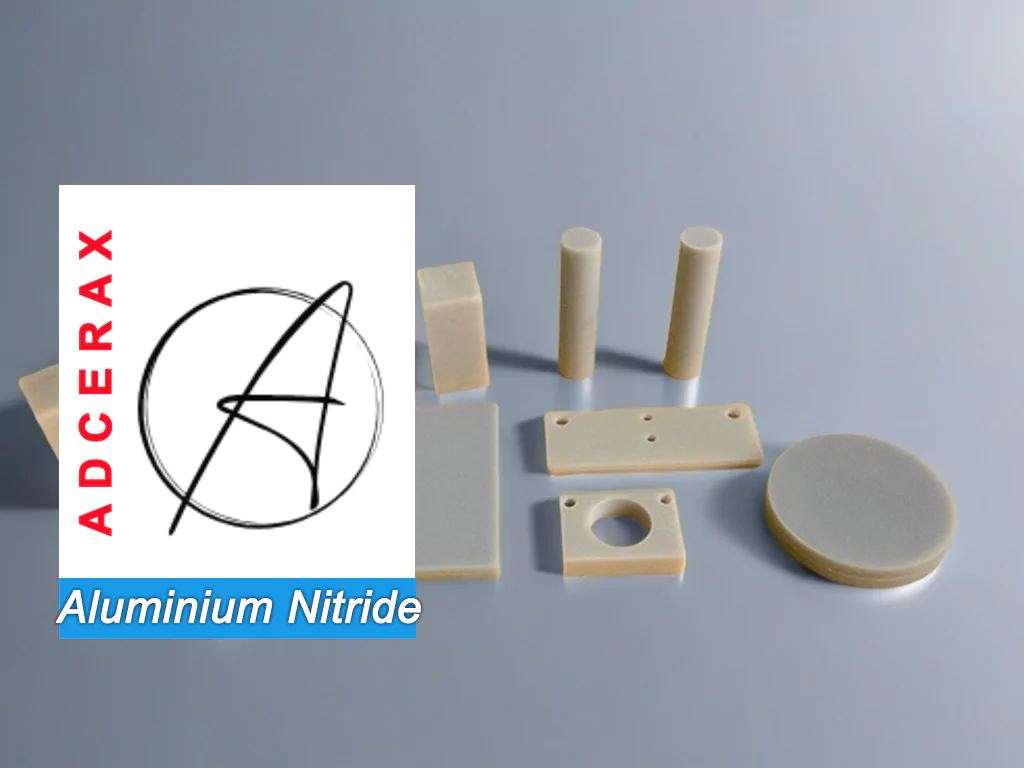

ADCERAX is a dedicated manufacturer of custom aluminum nitride substrates built to meet the thermal and mechanical needs of advanced power, LED and RF assemblies.

We supply bare AlN plates, metallized substrates and DBC AlN boards, supporting both standard formats and fully customized layouts for diverse electronic packaging requirements.

As a aluminum nitride substrate manufacturer, we offer stable quality, responsive engineering support, flexible small-batch to volume production and reliably controlled lead times—helping customers move faster with fewer supply risks.

170–200 W/m·K

Reliable heat spreading for power, LED and RF devices

Stable thickness, flatness and machining accuracy

What Are Aluminum Nitride Substrates?

Aluminum nitride substrates are high‐thermal‐conductivity ceramic base plates engineered for electronic assemblies that must dissipate significant heat while maintaining electrical insulation. Their thermal conductivity typically reaches 170–200+ W/m·K, allowing heat to be transferred away from power devices, LEDs, RF dies and laser chips with minimal temperature rise.

When to Use Aluminum Nitride Ceramic Substrates

Aluminum nitride substrates are selected when an electronic system must combine high heat removal, electrical insulation and mechanical stability in a single carrier. They are typically used in situations where conventional alumina, metal-core boards or composite substrates cannot meet thermal or reliability requirements. Consider AlN when:

Use AlN when device temperatures rise quickly or when cooling surfaces are limited, such as in compact power modules, LED/UV LED arrays or RF power stages.

AlN is preferred when the substrate must isolate the circuit from the heatsink while maintaining an efficient thermal path for continuous or pulsed loads.

AlN maintains stable electrical and mechanical behavior across broad operating temperatures, supporting laser modules, power converters and measurement systems.

Adopt AlN when solder fatigue, die-attach cracking or warpage must be minimized during thermal cycling or high-frequency operation.

Choose AlN for packaging designs requiring stable metallization, DBC copper, tight pad geometry, laser windows or precision openings.

Where long operating life, stable performance and controlled thermal behavior outweigh material cost, AlN becomes the practical option.

Key Properties of Aluminum Nitride Substrate

Aluminum nitride substrates provide stable thermal performance, low thermal expansion, strong electrical insulation and reliable structural integrity under continuous or cyclic heat load. Their dense ceramic body maintains flatness, minimizes warpage and supports consistent thermal paths essential for high-performance electronic assemblies.

Aluminum Nitride Substrate Technical Data

| Property Sort | Property Content | Unit | ALN-170 | ALN-200 | ALN-230 |

Basic | Color | gray | light yellow | light yellow | |

| Density | g/cm³ | 3.2-3.3 | 3.2-3.3 | 3.2-3.3 | |

| Surface Roughness | μm | 0.2-0.75 | 0.2-0.75 | 0.2-0.8 | |

| Camber | length ‰ | ≤3‰ | ≤3‰ | ≤3‰ | |

| Hardness | HV | 1100 | 1100 | 1100 | |

Thermal Properties | Max Operating Temperature | °C | 1100 | 1100 | 1100 |

| Thermal Conductivity | W/m·K | 170-190 | 190-220 | 220-230 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(20-400°c) | 4-5 | 4-5 | 4-5 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(400-800°c) | 5-6 | 5-6 | 5-6 | |

Mechanical Properties | Flexural Strength | MPa | 300-400 | 350-450 | 400-500 |

| Tensile Strength | MPa | 200-300 | 250-350 | 280-380 | |

| Compressive Strength | MPa | 2000-3000 | 2200-3200 | 2500-3500 | |

Electrical properties | Dielectric Constant | at 1MHz | 8-9 | 8-9 | 8-9 |

| Dielectric strength | KV/mm | ≥15 | ≥15 | ≥15 | |

| Volume resistivity | 20℃ Ω.cm | ≥1014 | ≥1014 | ≥1014 |

- This chart displays the typical properties of aluminum nitride (AlN) materials used in our standard products. Please note: Customized parts may have adjusted characteristics depending on production methods, with specific parameters determined by the stabilizer type and formula chosen for your application.

Advantages of AlN Substrate

AlN efficiently transfers heat away from power devices, LEDs and RF chips, supporting stable operation under continuous and transient loads.

The ceramic matrix provides strong dielectric isolation, enabling compact layouts while maintaining predictable behavior across wide temperature ranges.

Its thermal expansion aligns closely with Si, GaN and SiC dies, minimizing stress and ensuring reliable solder joints and stable geometry.

AlN substrates support tailored pad patterns, vias, slots and surface finishes, combined with tight tolerances for high-quality electronic packaging.

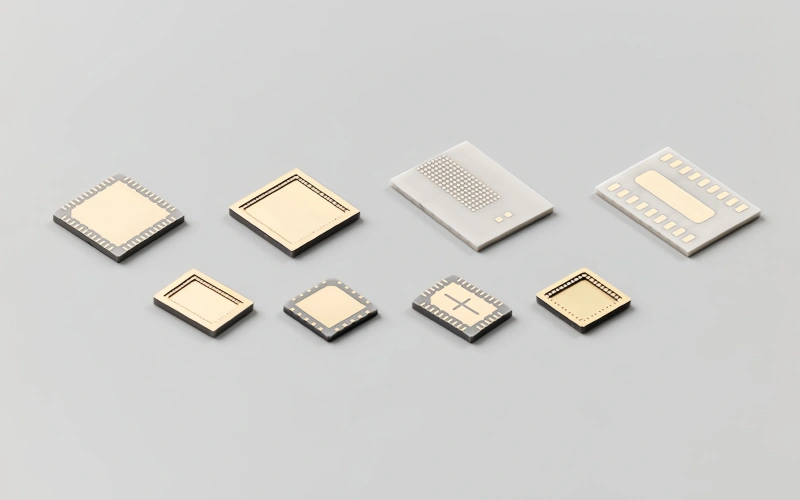

Aluminum Nitride Substrate Product Families from ADCERAX

ADCERAX supplies aln substrates in multiple formats, including bare AlN plates, metallized AlN substrates, DBC AlN copper-bonded boards, and custom-shaped AlN carriers produced for different packaging layouts. Standard sizes are available, and fully customized outlines, pad designs and thickness options can be manufactured according to drawings or project requirements.

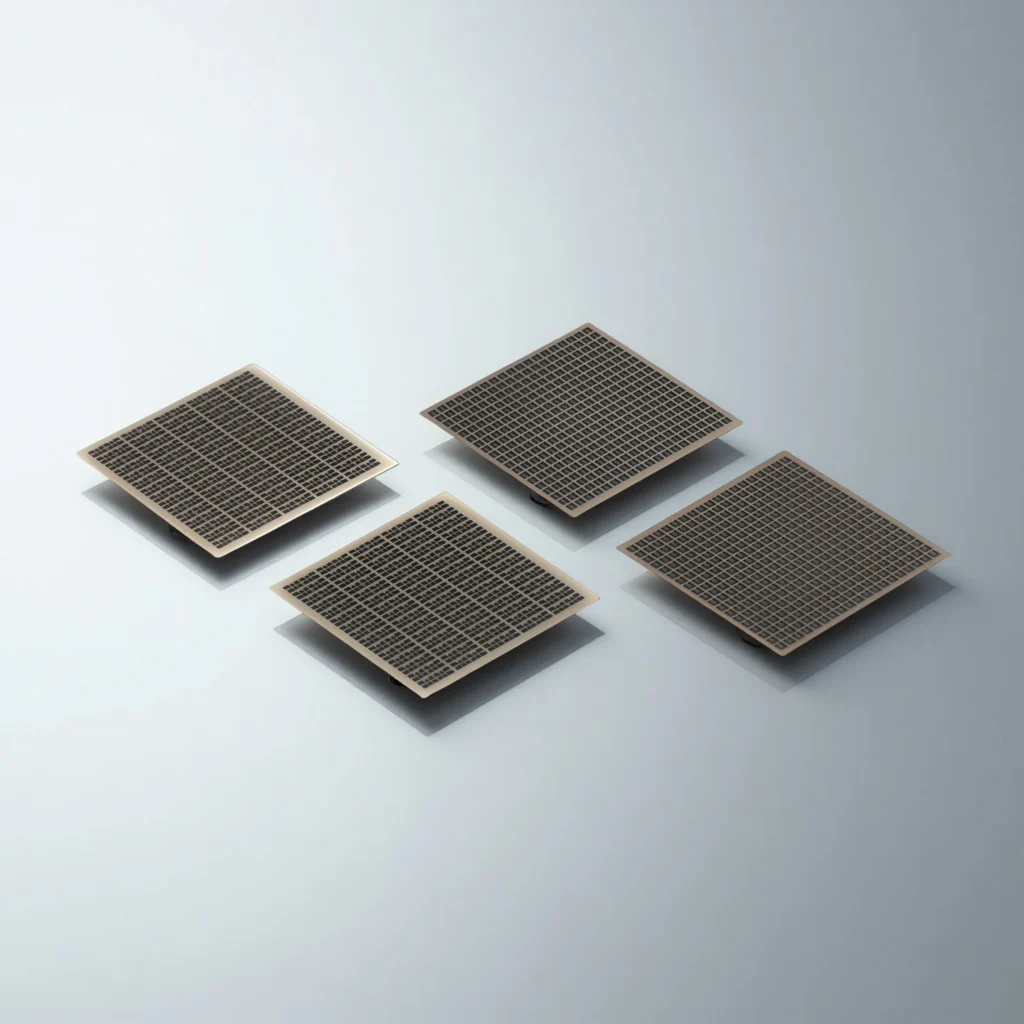

Metalized aluminum nitride substrates provide a stable base for power devices, LED/UV emitters and RF components where efficient heat spreading and reliable electrical insulation must work together. Their metalized pads allow secure die attach, wire bonding and thermal interfaces in compact electronic modules across power conversion, optical systems and high-frequency assemblies.

- Metalized pads support stable die attach and wire-bond reliability

- Low-resistance thermal paths help control junction temperature rise

- Pad layout customizable for different device footprints and packaging needs

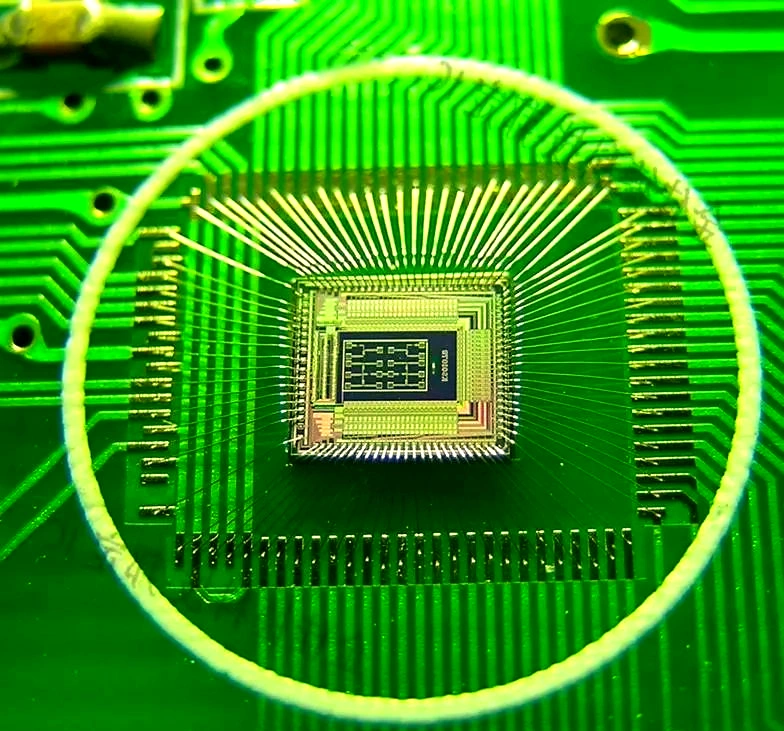

Aluminum nitride ceramic packaging shells are used in power devices, LED/UV LED modules, RF components and optical assemblies where the package must combine high thermal conductivity with stable electrical insulation. Their rigid AlN structure provides a reliable housing for dies, bond pads and internal interconnects, helping maintain controlled heat flow and dimensional stability in compact electronic packages.

- Provides a thermally efficient enclosure for heat-dense assemblies

- Supports reliable electrical isolation for RF, LED and optical circuits

- Customizable cavity, thickness and pad layout for precise integration

Bare aluminum nitride substrates serve as thermally conductive, electrically insulating base plates for power devices, LED/UV LED chips, RF components and precision sensor assemblies. They provide a clean ceramic platform for designers who require stable dielectric performance and efficient heat spreading before any metallization or circuit pattern is added.

- Delivers a stable thermal path for power, LED and RF device mounting

- Maintains reliable dielectric insulation for compact electronic layouts

- Supports custom thicknesses and dimensions for diverse packaging needs

Optical communication module AlN substrates provide a stable, thermally efficient base for TOSA/ROSA units, laser drivers and high-speed transceivers. Their balanced thermal behavior, insulation performance and dimensional accuracy help maintain signal integrity, manage device temperatures and support long-term reliability in compact optical modules.

- Ensures stable device temperature for laser and photodiode operation

- Supports high-speed signal performance with low dielectric loss

- Maintains precise alignment for optical paths and coupling structures

💡Power, LED, RF or optics—get the AlN substrate that makes your design work better.

ADCERAX delivers aluminum nitride substrates engineered for stable thermal behavior, clean electrical isolation and reliable dimensional control across power, LED, RF and optical modules. Share your drawing or target specs to get fast engineering support and a firm lead time.

Typical Applications of AlN Substrates

Aluminum nitride substrates are used in power electronics modules, LED/UV LED packaging, RF and 5G microwave circuits, laser and photonic assemblies, high-density sensor platforms, and precision industrial control systems where high thermal conductivity and electrical insulation are required.

🔌Power Electronics Modules

🧩 Key Advantages:

- AlN substrates lower module thermal resistance significantly, cutting SiC/IGBT junction temperature rise by 8–15 °C compared with 96% alumina in the same footprint.

- Better CTE match to Si/SiC reduces solder fatigue and extends power-cycling lifetime by 2×–4× under ΔTj stress conditions.

- AlN maintains insulation strength and mechanical integrity during fast switching, enabling 20–40% higher continuous power density in compact module layouts.

🔹Problem Solved:

A mid-power UV-C module manufacturer faced lumen decay above 10% after 500 hours due to poor thermal spreading in alumina boards. Switching to ADCERAX AlN substrates reduced junction temperature by 14–18°C in a 4-die array, stabilizing optical output and extending L70 life by over 1,000 hours. Their binning consistency improved by 22%, cutting rework and yield losses across three production lines.

📶RF, Microwave and 5G Power Amplifiers

🧩 Key Advantages:

- Maintains low loss and stable dielectric characteristics under high RF drive and elevated case temperatures.

- Supports dense PA architectures by reducing localized hot spots and improving device temperature uniformity.

- Supports dense PA architectures by reducing localized hot spots and improving device temperature uniformity.

🔹Problem Solved:

A 5G small-cell PA supplier experienced 7–9% gain drift during high-power tests due to substrate warpage from alumina. After switching to ADCERAX AlN substrates, device warpage dropped below 15 µm, thermal spread improved by 21%, and PA output remained stable across 200 temperature cycles. Field return rates for the PA module decreased from 1.8% to 0.6% within one quarter.

💡LED and UV LED Packaging

🧩 Key Advantages:

- AlN substrates keep UV LED junction temperatures within a narrow thermal band, supporting stable radiant output under continuous drive.

- AlN enables precise pad spacing and metallization alignment for high-density COB and UV emitter arrays.

- High thermal uniformity of AlN slows lumen depreciation in high-flux white LEDs and UV-C disinfecting modules.

🔹Problem Solved:

- A mid-power UV-C module manufacturer faced lumen decay above 10% after 500 hours due to poor thermal spreading in alumina boards. Switching to ADCERAX AlN substrates reduced junction temperature by 14–18°C in a 4-die array, stabilizing optical output and extending L70 life by over 1,000 hours. Their binning consistency improved by 22%, cutting rework and yield losses across three production lines.

⚙️Industrial Power Supplies and Measurement Systems

🧩 Key Advantages:

- Supports stable power delivery in converters, HV supplies and instrumentation operating under long duty cycles.

- Supports stable power delivery in converters, HV supplies and instrumentation operating under long duty cycles.

- Ensures mechanical consistency required for high-precision measurement, sensing and control equipment.

🔹Problem Solved:

An industrial HV power supply producer faced calibration drift in their feedback circuits as alumina substrates caused 12–15°C thermal hotspots near sensing areas. After adopting ADCERAX AlN substrates, hotspot temperature dropped by 30–35%, long-term drift reduced by 40%, and recalibration intervals extended from 3 months to over 6 months. Production scrap related to thermal deviation decreased by 18%.

Custom Aluminum Nitride Substrates and Engineering Support

We specialize in custom aluminum nitride (AlN) substrate solutions based on customer drawings, samples, or device-level packaging requirements. Tailored dimensions, thickness ranges, pad layouts, via patterns, cavities, and surface finishes can be produced to match semiconductor, LED, RF and photonic package designs. Custom AlN substrates typically require 3–9 weeks depending on layout complexity and machining needs.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

ADCERAX – aluminum nitride (AlN) substrate manufacturers

ADCERAX is a China-based aluminum nitride substrate manufacturer providing engineered AlN plates, metallized substrates and DBC AlN boards for power, RF and optical devices. As a aln substrates wholesale from China, we focus on stable quality, precise machining and flexible customization for both sampling and volume production.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

ADCERAX provides integrated manufacturing for aluminum nitride substrates, combining forming, high-temperature sintering, precision machining, metallization, and inspection into a unified workflow. We support bare AlN plates, metallized layouts, DBC copper–AlN boards, and custom geometries for power electronics, LED/UV modules, RF devices and photonic assemblies. Prototype and large-batch orders are both available.

-

Precision Machining & Dimensional Accuracy:

AlN substrates are produced with controlled forming and CNC machining to achieve stable thickness, flatness and pad geometry. Smooth surfaces and tight tolerances ensure reliable die-attach behavior, low warpage and consistent thermal paths across different device architectures. -

Batch Stability & Quality Control:

Every batch undergoes inspection for material purity, sintering integrity, density uniformity and dimensional repeatability. Controlled microstructure and furnace atmosphere compatibility help maintain low warpage, stable dielectric properties and predictable thermal performance for high-power assemblies. -

Customization & Engineering Support:

We offer drawing-based customization for outline sizes, thickness selections, slotting, vias, cavity designs, pad layouts and metallization schemes. Engineering support ensures compatibility with device footprints, bonding methods and system-level thermal requirements in power, LED, RF and optical packaging workflows.

ADCERAX specializes in manufacturing aluminum nitride substrates through controlled powder processing, high-temperature sintering, precision machining and strict dimensional inspection. Our AlN substrates offer stable thermal behavior, strong dielectric insulation, and reliable mechanical integrity for power, LED, RF and photonic packaging. Consistent thickness, low warpage and clean, defect-free surfaces ensure dependable performance in device bonding, metallization and high-density assembly workflows. These strengths make our substrates suitable for electronics manufacturers, module designers and OEM engineering teams that require stable, high-performance ceramic carriers.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Item | Typical Value / Description | ||

| Material Grades | High-thermal-conductivity AlN ceramic with controlled microstructure, suitable for power devices, LED/UV modules, RF circuits and photonic packaging. | ||

| Precision Machining | CNC and laser machining deliver stable thickness, clean edges and outline tolerances typically held within ±0.05–0.10 mm. | ||

| Forming & Shaping | Support for custom substrate formats including rectangles, squares, stepped profiles, cavities, vias, and metallization-ready surfaces. | ||

| Flatness & Dimensional Control | Stabilized sintering ensures low warpage, predictable flatness and uniform dimensions across production batches. | ||

| Inspection & Quality Control | Full inspection of thickness, flatness, chipping, metallization readiness and surface integrity to meet power, LED and RF packaging requirements. | ||

FAQs About Aluminum Nitride Substrates

Electronic-grade AlN substrates commonly use high-purity sintered grades such as 170 W/m·K, 180 W/m·K and 200 W/m·K thermal-conductivity classes, produced with low-oxygen, fine-grain ceramic powder. These grades provide consistent heat-spreading performance, stable dielectric properties and predictable machining response required for power devices, LED/UV modules, RF circuits and photonic packaging.

Below is a clean, professional English comparison table showing the differences between AlN, alumina, and BeO for thermal-management applications, followed by a clear engineering conclusion that helps decide.

| Property | Aluminum Nitride (AlN) | Alumina (Al₂O₃) | Beryllium Oxide (BeO) |

|---|---|---|---|

| Thermal Conductivity | High, suitable for dense power and RF heat loads | Moderate, insufficient for high-power devices | Very high, comparable to metal-like heat conduction |

| Electrical Insulation | Strong dielectric behavior with stable performance | Strong dielectric behavior | Strong, but may vary with temperature |

| CTE Match to Si / GaN / SiC | Good alignment; supports long-term cycling reliability | Weaker CTE match; higher stress on joints | Good match but sensitive to microstructural defects |

| Mechanical Strength | Balanced, adequate for thin substrates | High strength, good for structural ceramics | Good, but can be brittle under thermal shock |

| Processing & Machining | More challenging but stable after finishing | Easy to machine and mass-produce | Difficult; dust requires strict controls |

| Toxicity / Handling Safety | Safe ceramic with no regulatory restrictions | Safe and widely used | Toxic; requires regulated handling and specialized equipment |

| Typical Use Cases | Power modules, RF circuits, UV/LED, laser drivers | General electronics, sensors, non-critical thermal parts | Niche high-performance modules where safety risks are acceptable |

Aluminum nitride offers a strong balance of thermal conductivity, electrical insulation, CTE alignment and safety, making it the practical choice for high-power, LED/UV and RF applications where alumina cannot meet thermal limits and BeO introduces unacceptable safety and regulatory concerns.

Yes. Aluminum nitride substrates support a wide range of metallization systems designed for solder attach, die bonding, wire bonding and high-reliability package integration. Depending on the assembly flow, several metallization stacks can be applied:

Mo–Mn / W–Mo thick-film systems

Fired metallization that forms strong bonding layers suitable for Ni/Au plating, hermetic sealing and high-temperature applications.Ti / Ti–W / Ti–Cu seed layers

Used for sputtering or electroplating processes where thin, uniform adhesion layers are required for Cu, Ni, or Au buildup.Ni / Au finishes

Common for wire bonding (Au wire), low-void solder attach, and corrosion-resistant pad surfaces. Thickness can be tuned for RF, LED and photonics.Direct Ag or Cu pads

Applied for high-current modules, LED packaging, or applications that require low electrical resistance and efficient heat spreading.DBC (Direct Bonded Copper) on AlN

Copper layers bonded directly to AlN, enabling high-power modules, busbars, and packages with demanding thermal cycling.

These metallization options allow AlN substrates to interface with solder alloys, epoxy die-attach materials, ultrasonic wire bonding, flip-chip processes, and high-power module assemblies, offering flexibility for both prototype and mass-production environments.

Yes. Laser machining allows precise vias, cavities, micro-channels and custom openings with clean edges and minimal thermal impact, supporting RF circuits, photonic modules and dense multi-layer packaging.

AlN substrates can be fabricated into irregular contours, deep cavities, stepped profiles, chamfers, slots, rounded edges, and hybrid 2D/2.5D geometries through CNC machining and laser processing to match complex package architectures.

Drawings with dimensions, thickness, tolerance targets, metallization layers, via details, flatness requirements, surface finish, and intended application environment.

Yes. ADCERAX supplies bare plates, aln substrates metallized with customized conductor patterns and fully copper-clad aln dbc substrate solutions. For each dbc aln substrate design, we review copper thickness, isolation spacing and pad geometry before releasing it to production.

Yes. We support small engineering batches so that design teams can qualify our aln ceramic substrates before committing to volume. This is especially useful when migrating from another aln substrate supplier or when redesigning a module.

Aluminum nitride (AlN) substrates price varies with thickness, metallization type, tolerance class and batch size. In the electronic market, high-precision or complex layouts typically cost more due to tighter inspection and machining requirements.

You can explore direct-factory offerings from ADCERAX (a major aluminum nitride substrate manufacturer) for bulk orders—our China-based operations streamline engineering support, competitive unit pricing and versatile batch sizes for large-volume supply.

📍 For immediate inquiry: email info@adcerax.com or WhatsApp +86 19311583352, and request our current wholesale price list and MOQ terms.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Start Your Aluminum Nitride Substrate Project with ADCERAX

As one of the leading aluminum nitride substrate manufacturers in China, ADCERAX supports high-volume orders and global clients looking for AlN substrates wholesale in China.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours