Machinable Glass Ceramic Solutions for Vacuum, Heating and Electrical Insulation

ADCERAX is a machinable glass ceramic manufacturer in China, offering rods, bars, blocks, discs, rings and fully machined components produced directly to your drawings.

With factory-direct pricing, engineering support and flexible MOQs, we help you choose the right machinable glass ceramic grade and optimize tolerances and critical features for machining so your fixtures and insulating components are easier to produce and repeat.

👉 Send us your drawing and let ADCERAX turn your machinable glass ceramic challenge into a stable, high-performance solution delivered on time.

What Are Machinable Glass Ceramics?

Machinable Glass Ceramic Definition

Machinable glass ceramic is a mica-based glass-ceramic that can be drilled.

Matrix: glass-ceramic

Typically a borosilicate or silicate glass that, after controlled crystallization heat treatment, develops fine crystalline phases to form a glass-ceramic microstructure.

Main crystalline phase: mica-type crystals (usually tetrasilicic mica)

These plate-like mica crystals are oriented in specific directions, turning an originally brittle glass into a body filled with reinforcing lamellae that can slip and crack without losing overall stability, which markedly improves chip formation and fracture behavior during cutting and machining.

How Machinable Glass Ceramic Differs From Traditional Ceramics?

Processing route

-

Conventional ceramics:

formed first (pressing, injection, tape casting, etc.), then high-temperature sintering, followed by limited grinding or lapping. Sintering shrinkage is large and early tooling/process costs are high. -

Machinable glass ceramic:

supplied as pre-crystallized plates, rods and blocks that are brought directly to final size by mechanical machining, with no post-sintering firing step.

Dimension and tolerance control

-

Conventional ceramics:

final dimensions are strongly affected by sintering behaviour, so tight tolerances often require complex process control and post-grinding. -

Machinable glass ceramic:

there is no sintering shrinkage variable; tolerances depend mainly on machining capability, which makes it easier to hold precise fits on small batches and prototypes.

Mechanical performance and machinability

-

Conventional ceramics:

alumina, Si₃N₄, SiC and similar materials offer higher strength and fracture toughness, but are difficult and costly to machine once fired. -

Machinable glass ceramic:

has lower structural strength, but is softer and fractures into small chips more readily, making it much more suitable for turning, milling and drilling with conventional tools.

Design flexibility and project economics

-

Conventional ceramics:

fine slots, blind holes, internal threads and complex 3D features often demand special forming tools or grinding setups, driving up development time and cost. -

Machinable glass ceramic:

the same complex geometries can be cut directly from stock shapes, enabling fast design changes, shorter lead times and economical production of functional jigs and small-batch parts.

Machinable Glass Ceramic Advantages

Machinable glass ceramic lets projects start with standard stock sizes and simple machining programs, so you can validate concepts without investing in dedicated ceramic molds, presses or complex sintering trials.

When dimensions or hole patterns change late in the design, programmers only update machining paths instead of re-qualifying forming and firing routes, keeping changes fast and overall predictable.

If a fixture or insulating component cracks in service, it is easy to section, re-measure and adjust geometry, then cut an improved part from the same batch—helping close the design loop from field feedback.

Because machinable glass ceramic is delivered as pre-crystallized stock with well-defined properties, qualifying a second source is simpler than traditional fired ceramics, reducing risk on equipment platforms.

Machinable Glass Ceramic Properties

Machinable glass ceramic combines stable thermal expansion, strong electrical insulation and clean machinability, making it ideal for precise high-temperature insulating fixtures and spacers.

Machinable Glass Ceramic Physical Properties

Machinable glass ceramic is a dense, low-porosity glass-ceramic that stays dimensionally stable in heat, vacuum and humid environments. It combines ceramic-like rigidity with moderate hardness, so parts are durable in service yet still practical to machine precisely.

| Property | Typical value | Notes |

|---|---|---|

| Purity | ≥ 99.9 % | Some grades can reach 99.99 % |

| Density | 2.5–2.6 g/cm³ | Archimedes method |

| Open porosity | ≤ 0.07 % | Effectively non-porous |

| Water absorption | 0 % | No measurable uptake |

| Colour | White | Clean, uniform appearance |

| Hardness (Mohs) | 4–5 (up to 6–7) | Depending on grade |

Machinable Glass Ceramic Thermal Properties

Machinable glass ceramic has a moderate thermal expansion and relatively low thermal conductivity, giving it good dimensional stability across typical heating and cooling cycles. These thermal properties make it suitable for high-temperature fixtures, insulating blocks and components that see repeated thermal cycling without severe distortion.

| Property | Typical value | Notes |

|---|---|---|

| Coefficient of thermal expansion (CTE) | 72 × 10⁻⁷ /°C | Average from −50 to 200 °C |

| CTE 25–300 °C | 90 × 10⁻⁷ /°C | For design over mid-range temperatures |

| CTE 25–600 °C | 112 × 10⁻⁷ /°C | |

| CTE 25–800 °C | 123 × 10⁻⁷ /°C | |

| Thermal conductivity | 1.7 W/m·K | At 25 °C |

| Continuous use temperature | ~800 °C | Long-term service |

| Short-term maximum temperature | ~1000 °C | Depends on load and atmosphere |

Machinable Glass Ceramic Mechanical Properties

Machinable glass ceramic offers ceramic-like stiffness and compressive strength, but with lower fracture toughness than structural ceramics such as alumina or silicon nitride. This balance means it can carry typical fixture and support loads reliably while remaining brittle enough to chip cleanly under controlled machining.

| Property | Typical value | Notes |

|---|---|---|

| Young’s modulus | ≈ 65 GPa | Room temperature |

| Flexural strength | ≥ 100 MPa | Three-point bending |

| Compressive strength | ≥ 500 MPa | Room temperature |

| Impact resistance | ≥ 2.56 kJ/m² | Indicative value for brittle fracture |

| Poisson’s ratio | ≈ 0.29 | |

| Shear modulus | ≈ 25 GPa | Derived from E and ν |

Machinable Glass Ceramic Electrical Properties

Machinable glass ceramic provides high volume resistivity and good dielectric strength over a wide temperature range, making it a reliable insulator in compact, high-voltage and high-temperature designs. These electrical properties suit it to standoffs, terminal blocks, spacers and support parts in power, vacuum and instrumentation equipment.

| Property | Typical value | Notes |

|---|---|---|

| Dielectric constant (1 kHz) | 6–7 | Measured at room temperature |

| Dielectric loss (tan δ, 1 kHz) | 1–4 × 10⁻³ | Measured at room temperature |

| Dielectric strength | > 40 kV/mm | Typical value for a 1 mm thick test specimen |

| Volume resistivity @ 25 °C | ≈ 1.0 × 10¹⁶ Ω·cm | Room temperature, high insulation level |

| Volume resistivity @ 200 °C | ≈ 1.5 × 10¹² Ω·cm | Elevated temperature, decreases vs. 25 °C |

| Volume resistivity @ 500 °C | ≈ 1.1 × 10⁹ Ω·cm | Hot condition, indicative high-temperature value |

Machinable Glass Ceramic Chemical Properties

Machinable glass ceramic has good chemical stability in hot water, steam and many dilute mineral acids, so surfaces stay clean and dimensionally stable in most lab and industrial environments. It is less resistant to strong alkalis, so contact with concentrated caustic solutions should be limited.

| Solution | Weight loss | Notes |

|---|---|---|

| 5 % HCl | 0.26 mg/cm² | Acid resistance |

| 5 % Na₂CO₃ | 0.012 mg/cm² | Alkali, mild carbonate |

| 5 % NaOH | 0.85 mg/cm² | Strong alkali |

Machinable Glass Ceramic Products

Machinable glass ceramic products from ADCERAX include plates, rods, tubes, rings and custom parts for high-temperature, high-voltage and vacuum equipment. Choose from stock blanks or send drawings for engineered solutions.

Machinable glass ceramic plate is a flat insulating slab that can be milled, drilled and pocketed with standard CNC tools for jigs, carrier plates and structural inserts in high-temperature or vacuum equipment.

- Ideal for machining custom slots, pockets and mounting holes in one rigid plate

- Good dimensional stability across heating and cooling cycles

- Available in multiple thicknesses and formats for prototypes, series fixtures and custom jigs.

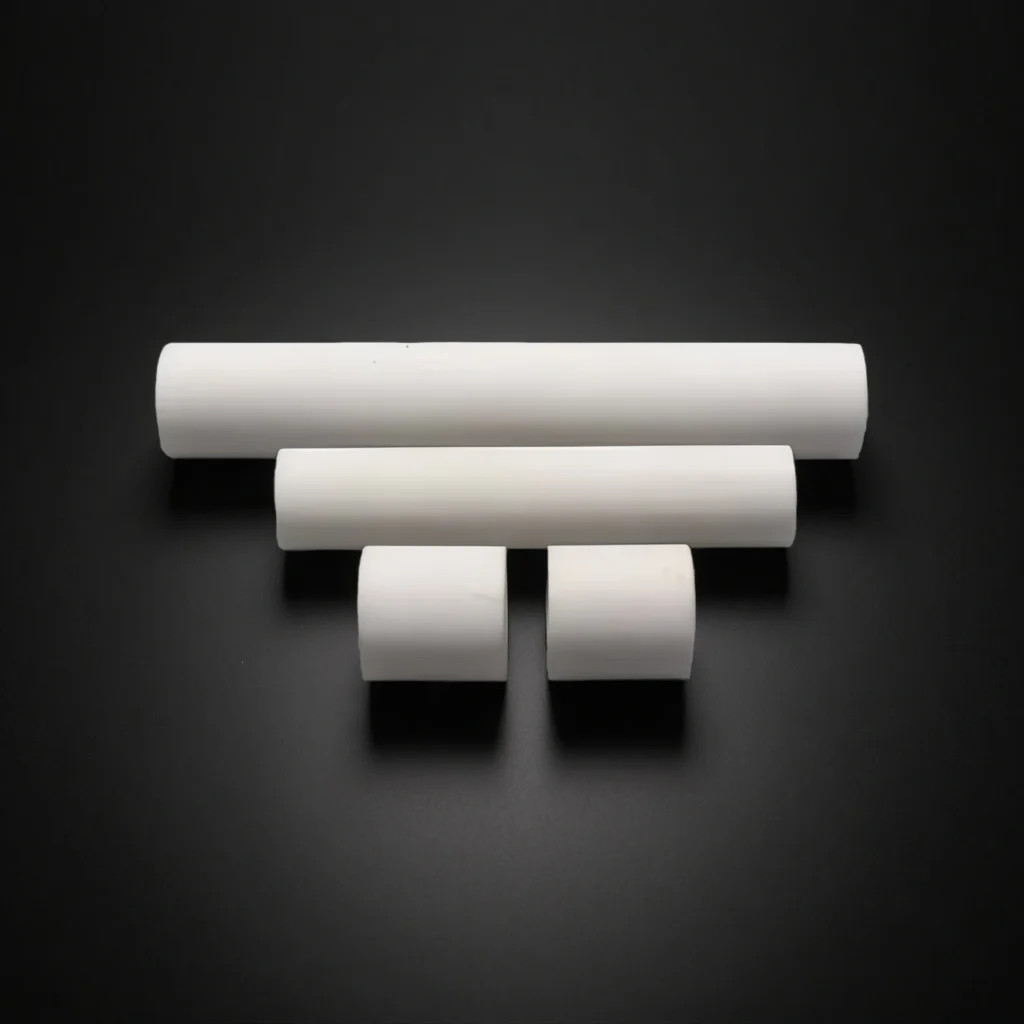

Machinable glass ceramic rod is a cylindrical blank used for spacers, standoffs and bushings where electrical insulation and thermal stability are required.

- Can be turned, grooved and threaded with conventional lathes and tooling

- Provides reliable insulation in compact heater, sensor and power assemblies

- Supplied in a range of diameters and lengths to support both samples and production runs

Machinable glass ceramic tube is a dense insulating sleeve that can be cut, drilled and grooved with standard tools for high-temperature and vacuum fixtures.

- Stable electrical insulation in compact heater and HV assemblies

- Good straightness and wall control for precise machining

- Multiple diameters and lengths for prototypes and series parts

Machinable glass ceramic ring is used as an insulating spacer or collar around shafts, flanges and optics where tight fit and thermal stability are required.

- Accurate ID/OD machining for alignment and shimming

- Low porosity surfaces suited to vacuum and analytical equipment

- Grooves, chamfers and bolt circles can be added by CNC

Machinable glass ceramic components are custom components made to your drawings, combining ceramic insulation with flexible CNC machining.

- Ideal for fixtures, spacers, terminal blocks and structural inserts

- Supports one-off prototypes and small batches without molding tools

- Allows complex slots, threads and pockets in a single rigid part

🔥Reliable machinable glass ceramic solutions for high-temperature, high-voltage and vacuum equipment

Rely on ADCERAX when you need machinable glass ceramic parts that stay stable in heat, voltage and vacuum. Share your drawing and operating conditions, and our engineers will recommend a practical design and quotation you can move to production with confidence.

Machinable Glass-Mica Ceramic Applications

Machinable glass-mica ceramic is used for high-temperature electrical insulation, precision fixtures and supports in power, vacuum and laboratory equipment. It suits coil formers, spacers, rings and custom insulating parts where designs change frequently but reliability must remain high.

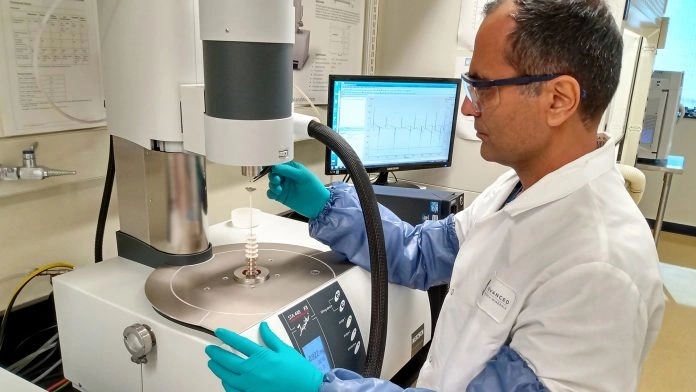

Lab and Analytical Instrument Fixtures

🔹Typical parts (machinable glass ceramic examples)

- Support plates and shims for sample holders

- Electrical feed-through insulators and terminal blocks

- Precision spacers around detectors, coils or optical components

- Low-outgassing fixtures inside small vacuum chambers

🔹Why choose machinable glass ceramic

- Stable insulation close to hot zones where plastics or epoxies are not acceptable

- Complex grooves, pockets and holes can be machined into one piece instead of assembling many parts

- Easy design changes when research teams iterate hardware between experiments

Industrial Heating, Soldering and Brazing Fixtures

🔹Typical parts (machinable glass ceramic examples)

- Fixture bases for brazed or soldered assemblies

- Masking shields and thermal barriers

- Insulating supports that carry heater coils or bus bars

🔹Why choose machinable glass ceramic

- Resists temperatures where many metals soften or oxidize faster than required

- Electrically insulates heater elements and live conductors from grounded metal structures

- Because fixtures are often project-specific, the ability to re-machine or adjust features is valuable during commissioning

High-voltage electrical insulation components

🔹Typical parts (machinable glass ceramic examples):

- Standoff insulators and posts

- Bus bar supports and mounting blocks

- Custom terminal boards and feed-through supports

🔹Why choose machinable glass ceramic

- High dielectric strength combined with dimensional stability enables compact designs

- Complex creepage paths can be machined into one solid piece

- Safer than many polymers at high temperature because there is no risk of melting or dripping near conductors

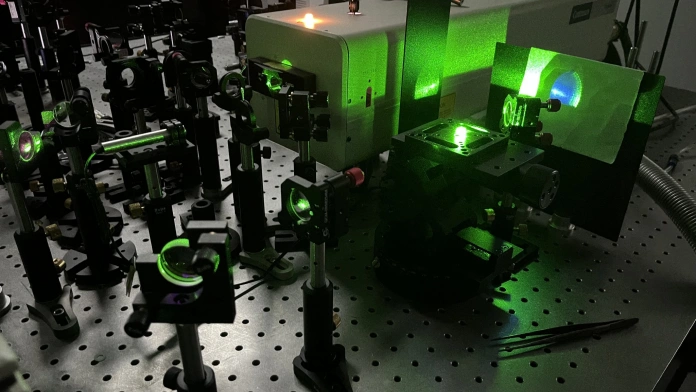

Laser and Optics Mechanical Insulation Parts

- Optical bench inserts for thermal isolation

- Insulating supports for laser diodes, drivers and current leads

- Spacers and rings around lenses or mirrors near hot components

🔹Why machinable glass ceramic:

- Low thermal expansion compared with many metals helps maintain optical alignment

- Electrical insulation allows a compact layout in tight optical heads

- Fine features such as threaded holes and counterbores can be machined in small parts

Custom machinable glass ceramic Supplier

We specialize in custom machinable glass ceramic parts based on customer drawings, samples or application requirements. Dimensions, wall thicknesses, holes, threads and complex geometries in plates, rods, tubes, rings and fixtures can be tailored to your operating conditions. Custom machinable glass ceramic components typically require 3–9 weeks depending on design complexity, machining tolerances and surface-finish specifications.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Why Choose ADCERAX as Your Machinable Glass Ceramic Manufacturer?

ADCERAX is a machinable glass ceramic manufacturer in China, providing factory-direct pricing, engineering support and flexible customization from blanks to finished parts. With tight tolerance control and reliable global shipping, we make sourcing machinable glass ceramic components simple and low risk.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

China Machinable Glass Ceramic Factory-ADCERAX

ADCERAX has worked in advanced ceramics for over 20 years and has developed more than 2,000 types of precision parts, with a strong focus on machinable glass ceramic.

We offer custom and standard machinable glass ceramic components for different equipment designs, and our products are exported to over 50 countries worldwide, supporting industrial users and equipment manufacturers that need stable insulating parts.

Glass Mica Ceramic Machining

Machinable glass ceramic behave like brittle engineering materials during cutting, so successful machining depends on controlling edge chipping, tool load and thermal stress. The goal is to achieve clean, repeatable features without introducing microcracks that could shorten service life.

Tooling and Machine Setup

💡Machine choice

- Standard CNC machines for ceramic glass with good spindle condition and rigid fixturing are sufficient for most glass mica ceramic machining tasks.

- High-speed glass and ceramic processing machines or dedicated grinding centres are used only when cycle time or surface finish is critical.

💡Tooling selection

- Prefer sharp carbide or PCD tools with positive rake to reduce cutting forces.

- Use stable tool holders with minimal overhang to control vibration during machining glass-mica ceramic parts.

💡Cutting conditions

- Start with light depths of cut and moderate feed rates; adjust gradually while monitoring edge quality.

- Coolant or mist can be used where necessary, but avoid thermal shock and keep chips cleared from the cutting zone.

Process Recommendations

💡Turning and grooving

- Use smooth tool entry and exit, avoid plunging directly into sharp corners.

Leave small radii at groove bottoms and shoulders to reduce stress concentration and improve tool life.

💡Milling and pocketing

- Prefer climb milling with light radial engagement to minimise edge chipping along the walls.

- Ramp or helix into pockets instead of full-width plunging to reduce shock on the cutting edge.

💡Drilling and threading

- Peck drilling with controlled chip removal reduces risk of cracks at the exit side.

- For threads, consider thread milling or carefully controlled tapping with generous run-out and deburring of starts.

💡Ultrasonic machining of glass and ceramics

- Ultrasonic machining of glass and ceramics is reserved for very small holes, thin webs or intricate profiles where conventional cutting would generate excessive defects.

- It can improve edge quality on delicate features, but is usually not necessary for standard blocks, plates or rods.

Tips-for-Machining (DFM)

💡Avoid knife-edge features

- Keep minimum wall thickness and land widths above agreed limits; extremely sharp fins and edges are prone to chipping.

💡Use radii and chamfers wisely

- Add small corner radii or chamfers wherever possible to reduce stress concentrations and improve edge strength, especially around slots and pockets.

💡Separate critical and non-critical tolerances

- Tighten tolerances only where function requires it and relax non-critical dimensions; this reduces machining time and scrap risk.

💡Plan fixturing surfaces

- Include flat reference pads or clamping areas so the machinable glass ceramic part can be held securely without stressing functional sections.

ADCERAX Machinable Glass Ceramic Processing Capabilities

ADCERAX combines engineering support, drawing optimization and CNC machining assets dedicated to machinable glass ceramic. We turn plates, rods, tubes and rings into precise insulating components with stable quality for demanding industrial and laboratory equipment.

| Capability Category | Equipment / Specification | Engineering Value Provided |

|---|---|---|

| Precision CNC Machining | Vertical and horizontal CNC machining centers for glass ceramic | Stable dimensions and clean edges on plates, rods, tubes and rings |

| Fine Grinding & Surface Finish | Surface grinders, diamond wheels, lapping fixtures | Controlled flatness, parallelism and surface quality for sealing or bonding |

| Hole, Slot & Thread Machining | CNC drilling, tapping, thread milling and small-diameter tools | Accurate holes, grooves and threads for coil formers, spacers and hardware |

| Prototype & Small-Batch Runs | Flexible fixture systems, quick-change tooling | Fast turnaround for samples and low-volume custom machinable glass ceramic parts |

| Metrology & Inspection | CMM, optical measurement, gauges and dedicated inspection jigs | Consistent tolerances and documented quality for repeat production |

Machinable Glass Ceramic Quality & Certifications

FAQs About Machinable Glass Ceramic

Thanks to its controlled thermal expansion and low porosity, machinable glass ceramic maintains dimensions well across normal heating and cooling cycles. It is suitable for fixtures that see regular furnace cycles, provided mechanical loads are moderate and sharp temperature shocks are avoided.

In many designs, machinable glass ceramic can operate continuously in the mid-hundreds °C with higher short-term peaks, but the safe limit depends on load, atmosphere and part geometry. ADCERAX evaluates your real operating profile before confirming whether the material is appropriate or if another ceramic is safer.

It provides good compressive and bending strength for jigs, spacers, standoffs and light brackets but is not intended to replace high-strength structural ceramics in heavily loaded shafts or bearings. We usually recommend it where stiffness and alignment are important but ultimate load is modest.

Yes, it can be assembled using mechanical fasteners, suitable high-temperature adhesives or brazed interfaces if the joint is properly designed. We normally advise customers to rely on clamped or mechanically captured joints for easier maintenance and thermal compatibility.

Please provide 2D drawings (and 3D files if available), operating temperature and atmosphere, mechanical loads, annual usage, inspection requirements and any critical surfaces or tolerances. This allows ADCERAX engineers to suggest design adjustments, choose a suitable grade and quote accurately.

Yes, our engineers can review existing fixtures or sample parts, identify where ceramic insulation or thermal stability is beneficial, and propose machinable glass ceramic plate, rod or ring solutions. We often consolidate multi-part metal assemblies into fewer ceramic components to simplify builds.

We do not recommend it for severe mechanical shock, heavy impact, high-speed wear or environments dominated by strong hot alkali. In those cases, we usually propose alumina, silicon nitride, silicon carbide or boron nitride, depending on the failure risk and budget.

Yes, we regularly work under NDA with OEM customers. Drawings and process documents are handled under internal confidentiality procedures and are not shared with third parties.

If there is any non-conformity against the approved drawing or quotation, ADCERAX will investigate quickly and, after confirmation, arrange rework, replacement or other mutually agreed solutions.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours