Alumina ceramic balls are dense spherical components made from sintered aluminum oxide (Al₂O₃), valued for their high hardness, wear resistance and chemical stability. They are produced by pressing fine alumina powder into spheres—via isostatic pressing, granulation or molding—and sintering them at high temperature to achieve a strong, uniform microstructure.

Alumina Ball Bearings Benefits

-

Precision grades for bearing use

Alumina bearing balls can be manufactured to typical bearing grades such as G10–G40, supporting low run-out and stable rotational accuracy in full and hybrid ceramic bearings. -

Wear and corrosion resistance in aggressive media

Alumina balls resist abrasion and most corrosive media, including many acids, salts and solvents, which makes them suitable as rolling elements in chemical pumps, down-hole pumps and valves where metallic balls suffer from rapid wear. -

High-temperature bearing operation

With useful temperatures reported up to around 1600–1750°C, alumina ball bearings maintain mechanical strength and dimensional stability in high-temperature equipment and hot gases where steel balls soften or oxidize. -

Electrical insulation and non-magnetic behaviour

Alumina ceramics provide excellent electrical insulation and are non-magnetic, allowing alumina bearing balls to be used in electrically insulated bearings for motors, instruments and sensors, where eddy currents and magnetic interference need to be avoided. -

Low density compared with steel

The moderate density of alumina reduces centrifugal forces at high speed compared with steel, helping to limit contact stress and bearing heating in high-speed or intermittent duty cycles.

Alumina Ball Bearings Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

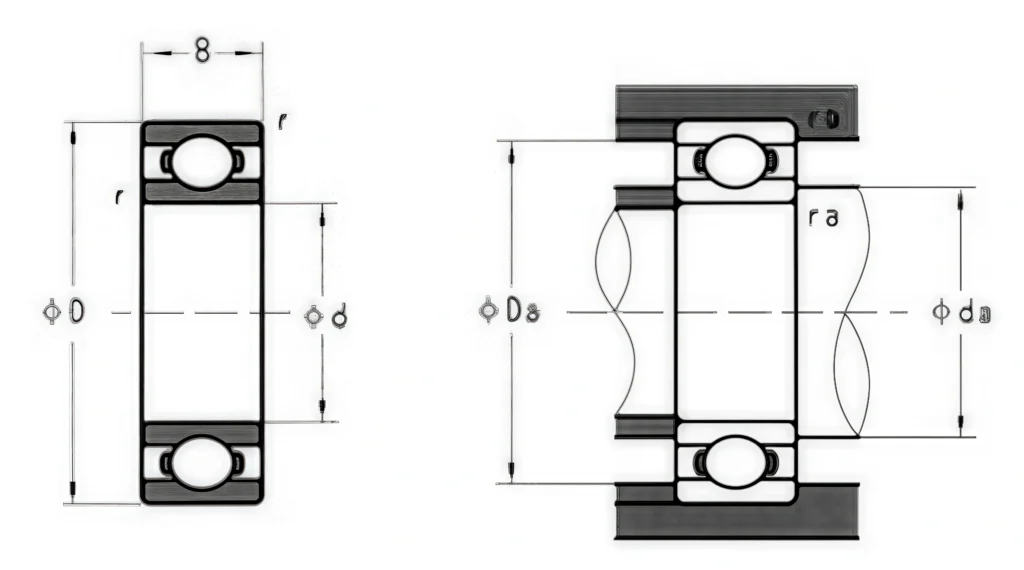

Alumina Ceramic Ball Bearings Specifications

| Alumina Bearing | |||||||||

| Item NO. | Model | Product Size (mm) | r (Min) | Install Size (mm) | |||||

| d(Inner Dia) | D(Outer Dia) | B(Height) | da (Min) | Max | Max | Max | |||

| AT-AB-ZC684CE | 684CE | 4 | 9 | 2.5 | 0.1 | 4.8 | / | 8.2 | 0.1 |

| AT-AB-ZC694CE | 694CE | 4 | 11 | 4 | 0.15 | 5.2 | / | 9.8 | 0.15 |

| AT-AB-ZC604CE | 604CE | 4 | 12 | 4 | 0.2 | 5.6 | / | 10.4 | 0.2 |

| AT-AB-ZC624CE | 624CE | 4 | 13 | 5 | 0.2 | 5.6 | / | 11.4 | 0.2 |

| AT-AB-ZC634CE | 634CE | 4 | 16 | 5 | 0.3 | 6 | / | 14 | 0.3 |

| AT-AB-ZC685CE | 685CE | 5 | 11 | 3 | 0.15 | 6.2 | / | 9.8 | 0.15 |

| AT-AB-ZC695CE | 695CE | 5 | 13 | 4 | 0.2 | 6.6 | / | 11.4 | 0.2 |

| AT-AB-ZC605CE | 605CE | 5 | 14 | 5 | 0.2 | 6.6 | / | 12.4 | 0.2 |

| AT-AB-ZC625CE | 625CE | 5 | 16 | 5 | 0.3 | 7 | / | 14 | 0.3 |

| AT-AB-ZC635CE | 635CE | 5 | 19 | 6 | 0.3 | 7 | / | 17 | 0.3 |

| AT-AB-ZC686CE | 686CE | 6 | 13 | 3.5 | 0.15 | 7.2 | / | 11.8 | 0.15 |

| AT-AB-ZC696CE | 696CE | 7 | 15 | 5 | 0.2 | 7.6 | / | 13.4 | 0.2 |

| AT-AB-ZC606CE | 606CE | 8 | 17 | 6 | 0.3 | 8 | / | 15 | 0.3 |

| AT-AB-ZC626CE | 626CE | 9 | 19 | 6 | 0.3 | 8 | / | 17 | 0.3 |

| AT-AB-ZC636CE | 636CE | 10 | 22 | 7 | 0.3 | 8 | / | 20 | 0.3 |

| AT-AB-ZC687CE | 687CE | 7 | 14 | 3.5 | 0.15 | 8.2 | / | 12.8 | 0.15 |

| AT-AB-ZC697CE | 697CE | 7 | 17 | 5 | 0.3 | 9 | / | 15 | 0.3 |

| AT-AB-ZC607CE | 607CE | 7 | 19 | 6 | 0.3 | 9 | / | 17 | 0.3 |

| AT-AB-ZC627CE | 627CE | 7 | 22 | 7 | 0.3 | 9 | / | 20 | 0.3 |

| AT-AB-ZC637CE | 637CE | 7 | 26 | 9 | 0.3 | 9 | / | 24 | 0.3 |

| AT-AB-ZC688CE | 688CE | 8 | 16 | 4 | 0.2 | 9.6 | / | 14.4 | 0.2 |

| AT-AB-ZC698CE | 698CE | 8 | 19 | 6 | 0.3 | 10 | / | 17 | 0.3 |

| AT-AB-ZC608CE | 608CE | 8 | 22 | 7 | 0.3 | 10 | / | 20 | 0.3 |

| AT-AB-ZC628CE | 628CE | 8 | 24 | 8 | 0.3 | 10 | / | 22 | 0.3 |

| AT-AB-ZC638CE | 638CE | 8 | 28 | 9 | 0.3 | 10 | / | 26 | 0.3 |

| AT-AB-ZC689CE | 689CE | 9 | 17 | 4 | 0.2 | 10.6 | / | 15.4 | 0.2 |

| AT-AB-ZC699CE | 699CE | 9 | 20 | 6 | 0.3 | 11 | / | 18 | 0.3 |

| AT-AB-ZC609CE | 609CE | 9 | 24 | 7 | 0.3 | 11 | / | 22 | 0.3 |

| AT-AB-ZC629CE | 629CE | 9 | 26 | 8 | 0.3 | 11 | / | 24 | 0.3 |

| AT-AB-ZC639CE | 639CE | 9 | 30 | 10 | 0.6 | 13 | / | 26 | 0.6 |

| AT-AB-ZC6800CE | 6800CE | 10 | 19 | 5 | 0.3 | 12 | 12 | 17 | 0.3 |

| AT-AB-ZC6900CE | 6900CE | 10 | 22 | 6 | 0.3 | 12 | 12.5 | 20 | 0.3 |

| AT-AB-ZC6000CE | 6000CE | 10 | 26 | 8 | 0.3 | 12 | 13 | 24 | 0.3 |

| AT-AB-ZC6200CE | 6200CE | 10 | 30 | 9 | 0.6 | 14 | 16 | 26 | 0.6 |

| AT-AB-ZC6300CE | 6300CE | 10 | 35 | 11 | 0.6 | 14 | 16.5 | 31 | 0.6 |

| AT-AB-ZC6801CE | 6801CE | 12 | 21 | 5 | 0.3 | 14 | 14 | 19 | 0.3 |

| AT-AB-ZC6901CE | 6901CE | 12 | 24 | 6 | 0.3 | 14 | 14.5 | 22 | 0.3 |

| AT-AB-ZC16001CE | 16001CE | 12 | 28 | 7 | 0.3 | 14 | / | 26 | 0.3 |

| AT-AB-ZC6001CE | 6001CE | 12 | 28 | 8 | 0.3 | 14 | 15.5 | 26 | 0.3 |

| AT-AB-ZC6201CE | 6201CE | 12 | 32 | 10 | 0.6 | 16 | 17 | 28 | 0.6 |

| AT-AB-ZC6301CE | 6301CE | 12 | 37 | 12 | 1 | 17 | 18 | 32 | 1 |

| AT-AB-ZC6802CE | 6802CE | 15 | 24 | 5 | 0.3 | 17 | 17 | 22 | 0.3 |

| AT-AB-ZC6902CE | 6902CE | 15 | 28 | 7 | 0.3 | 17 | 17 | 26 | 0.3 |

| AT-AB-ZC16002CE | 16002CE | 15 | 32 | 8 | 0.3 | 17 | / | 30 | 0.3 |

| AT-AB-ZC6002CE | 6002CE | 15 | 32 | 9 | 0.3 | 17 | 19 | 30 | 0.3 |

| AT-AB-ZC6202CE | 6202CE | 15 | 35 | 11 | 0.6 | 19 | 20.5 | 31 | 0.3 |

| AT-AB-ZC6302CE | 6302CE | 15 | 42 | 13 | 1 | 20 | 22.5 | 37 | 1 |

| AT-AB-ZC6803CE | 6803CE | 17 | 26 | 5 | 0.3 | 19 | 19 | 24 | 0.3 |

| AT-AB-ZC6903CE | 6903CE | 17 | 30 | 7 | 0.3 | 19 | 19.5 | 28 | 0.3 |

| AT-AB-ZC16003CE | 16003CE | 17 | 35 | 8 | 0.3 | 19 | / | 33 | 0.3 |

| AT-AB-ZC6003CE | 6003CE | 17 | 35 | 10 | 0.3 | 19 | 21.5 | 33 | 0.3 |

| AT-AB-ZC6203CE | 6203CE | 17 | 40 | 12 | 0.6 | 21 | 23.5 | 36 | 0.6 |

| AT-AB-ZC6303CE | 6303CE | 17 | 47 | 14 | 1 | 22 | 25.5 | 42 | 1 |

| AT-AB-ZC6403CE | 6403CE | 17 | 62 | 17 | 1.1 | 23.5 | / | 55.5 | 1 |

| AT-AB-ZC6804CE | 6804CE | 20 | 32 | 7 | 0.3 | 22 | 22.5 | 30 | 0.3 |

| AT-AB-ZC6904CE | 6904CE | 20 | 37 | 9 | 0.3 | 22 | 24 | 35 | 0.3 |

| AT-AB-ZC16004CE | 16004CE | 20 | 42 | 8 | 0.3 | 22 | / | 40 | 0.3 |

| AT-AB-ZC6004CE | 6004CE | 20 | 42 | 12 | 0.6 | 24 | 25.5 | 38 | 0.6 |

| AT-AB-ZC6204CE | 6204CE | 20 | 47 | 14 | 1 | 25 | 26.5 | 42 | 1 |

| AT-AB-ZC6304CE | 6304CE | 20 | 52 | 15 | 1.1 | 26.5 | 28 | 45.5 | 1 |

| AT-AB-ZC6404CE | 6404CE | 20 | 72 | 19 | 1.1 | 26.5 | / | 65.5 | 1 |

| AT-AB-ZC6805CE | 6805CE | 25 | 37 | 7 | 0.3 | 27 | 27 | 35 | 0.3 |

| AT-AB-ZC6905CE | 6905CE | 25 | 42 | 9 | 0.3 | 27 | 28.5 | 40 | 0.3 |

| AT-AB-ZC16005CE | 16005CE | 25 | 47 | 8 | 0.3 | 27 | / | 45 | 0.3 |

| AT-AB-ZC6005CE | 6005CE | 25 | 47 | 12 | 0.6 | 29 | 30 | 43 | 0.6 |

| AT-AB-ZC6205CE | 6205CE | 25 | 52 | 15 | 1 | 30 | 32 | 47 | 1 |

| AT-AB-ZC6305CE | 6305CE | 25 | 62 | 17 | 1.1 | 31.5 | 36 | 55.5 | 1 |

| AT-AB-ZC6405CE | 6405CE | 25 | 80 | 21 | 1.5 | 33 | / | 72 | 1.5 |

| AT-AB-ZC6806CE | 6806CE | 30 | 42 | 7 | 0.3 | 32 | 32 | 50 | 1 |

| AT-AB-ZC6906CE | 6906CE | 30 | 47 | 9 | 0.3 | 32 | 34 | 57 | 1 |

| AT-AB-ZC16006CE | 16006CE | 30 | 55 | 9 | 0.3 | 32 | 42.5 | 65.5 | 1 |

| AT-AB-ZC6006CE | 6006CE | 30 | 55 | 13 | 1 | 35 | 36.5 | 53 | 1 |

| AT-AB-ZC6206CE | 6206CE | 30 | 62 | 16 | 1 | 35 | 38.5 | 60 | 1 |

| AT-AB-ZC6306CE | 6306CE | 30 | 72 | 19 | 1.1 | 36.5 | 42.5 | 68.5 | 1 |

| AT-AB-ZC6406CE | 6406CE | 30 | 90 | 23 | 1.5 | 54 | / | 82 | 2 |

| AT-AB-ZC6807CE | 6807CE | 35 | 47 | 7 | 0.3 | 37 | 37 | 45 | 0.3 |

| AT-AB-ZC6907CE | 6907CE | 35 | 55 | 10 | 0.6 | 39 | 39 | 51 | 0.6 |

| AT-AB-ZC16007CE | 16007CE | 35 | 62 | 9 | 0.3 | 37 | / | 60 | 0.3 |

| AT-AB-ZC6007CE | 6007CE | 35 | 62 | 14 | 1 | 40 | 41.5 | 57 | 1 |

| AT-AB-ZC6207CE | 6207CE | 35 | 72 | 17 | 1.1 | 41.5 | 44.5 | 65.5 | 1 |

| AT-AB-ZC6307CE | 6307CE | 35 | 80 | 21 | 1.5 | 43 | 47 | 72 | 1.5 |

| AT-AB-ZC6407CE | 6407CE | 35 | 100 | 25 | 1.5 | 43 | / | 92 | 1.5 |

| AT-AB-ZC6808CE | 6808CE | 40 | 52 | 7 | 0.3 | 42 | 42 | 50 | 0.3 |

| AT-AB-ZC6908CE | 6908CE | 40 | 62 | 12 | 0.6 | 44 | 46 | 58 | 0.6 |

| AT-AB-ZC16008CE | 16008CE | 40 | 68 | 9 | 0.3 | 42 | / | 66 | 0.3 |

| AT-AB-ZC6008CE | 6008CE | 40 | 68 | 15 | 1 | 45 | 47.5 | 63 | 1 |

| AT-AB-ZC6208CE | 6208CE | 40 | 80 | 18 | 1.1 | 46.5 | 50.5 | 73.5 | 1 |

| AT-AB-ZC6308CE | 6308CE | 40 | 90 | 23 | 1.5 | 48 | 53 | 80 | 1.5 |

| AT-AB-ZC6408CE | 6408CE | 40 | 110 | 27 | 2 | 49 | / | 101 | 2 |

| AT-AB-ZC6809CE | 6809CE | 45 | 58 | 7 | 0.3 | 47 | 47.5 | 56 | 0.3 |

| AT-AB-ZC6909CE | 6909CE | 45 | 68 | 12 | 0.6 | 49 | 50 | 64 | 0.6 |

| AT-AB-ZC16009CE | 16009CE | 45 | 75 | 10 | 0.6 | 49 | / | 71 | 0.6 |

| AT-AB-ZC6009CE | 6009CE | 45 | 75 | 16 | 1 | 50 | 53.5 | 70 | 1 |

| AT-AB-ZC6209CE | 6209CE | 45 | 85 | 19 | 1.1 | 51.5 | 55.5 | 78.5 | 1 |

| AT-AB-ZC6309CE | 6309CE | 45 | 100 | 25 | 1.5 | 53 | 61.5 | 92 | 1.5 |

| AT-AB-ZC6409CE | 6409CE | 45 | 120 | 29 | 2 | 54 | / | 111 | 2 |

| AT-AB-ZC6810CE | 6810CE | 50 | 65 | 7 | 0.3 | 52 | 52.5 | 63 | 0.3 |

| AT-AB-ZC6910CE | 6910CE | 50 | 72 | 12 | 0.6 | 54 | 55 | 68 | 0.6 |

| AT-AB-ZC16010CE | 16010CE | 50 | 80 | 10 | 0.6 | 54 | / | 76 | 0.6 |

| AT-AB-ZC6010CE | 6010CE | 50 | 80 | 16 | 1 | 55 | 58.5 | 75 | 1 |

| AT-AB-ZC6210CE | 6210CE | 50 | 90 | 20 | 1.1 | 56.5 | 60 | 83.2 | 1 |

| AT-AB-ZC6310CE | 6310CE | 50 | 110 | 27 | 2 | 59 | 68 | 101 | 2 |

| AT-AB-ZC6410CE | 6410CE | 50 | 130 | 31 | 2.1 | 61 | / | 119 | 2 |

| AT-AB-ZC6811CE | 6811CE | 55 | 72 | 9 | 0.3 | 57 | 59 | 70 | 0.3 |

| AT-AB-ZC6911CE | 6911CE | 55 | 80 | 13 | 1 | 60 | 61.5 | 75 | 1 |

| AT-AB-ZC16011CE | 16011CE | 55 | 90 | 11 | 0.6 | 59 | / | 86 | 0.6 |

| AT-AB-ZC6011CE | 6011CE | 55 | 90 | 18 | 1.1 | 61.5 | 64 | 83.5 | 1 |

| AT-AB-ZC6211CE | 6211CE | 55 | 100 | 21 | 1.5 | 63 | 66.5 | 92 | 1.5 |

| AT-AB-ZC6311CE | 6311CE | 55 | 120 | 29 | 2 | 64 | 72.5 | 111 | 2 |

| AT-AB-ZC6411CE | 6411CE | 55 | 140 | 33 | 2.1 | 66 | / | 129 | 2 |

| AT-AB-ZC6812CE | 6812CE | 60 | 78 | 10 | 0.3 | 62 | 64 | 76 | 0.3 |

| AT-AB-ZC6912CE | 6912CE | 60 | 85 | 13 | 1 | 65 | 66 | 80 | 1 |

| AT-AB-ZC16012CE | 16012CE | 60 | 95 | 11 | 0.6 | 64 | / | 91 | 0.6 |

| AT-AB-ZC6012CE | 6012CE | 60 | 95 | 18 | 1.1 | 66.5 | 69 | 88.5 | 1 |

| AT-AB-ZC6212CE | 6212CE | 60 | 110 | 22 | 1.5 | 68 | 74.5 | 102 | 1.5 |

| AT-AB-ZC6312CE | 6312CE | 60 | 130 | 31 | 2.1 | 71 | 79 | 119 | 2 |

| AT-AB-ZC6412CE | 6412CE | 60 | 150 | 35 | 2.1 | 71 | 139 | 2 | |

| AT-AB-ZC6813CE | 6813CE | 65 | 85 | 10 | 0.6 | 69 | 69 | 81 | 0.6 |

| AT-AB-ZC6913CE | 6913CE | 65 | 90 | 13 | 1 | 70 | 71.5 | 85 | 1 |

| AT-AB-ZC16013CE | 16013CE | 65 | 100 | 11 | 0.6 | 69 | / | 96 | 0.6 |

| AT-AB-ZC6013CE | 6013CE | 65 | 100 | 18 | 1.1 | 71.5 | 73 | 93.5 | 1 |

| AT-AB-ZC6213CE | 6213CE | 65 | 120 | 23 | 1.5 | 73 | 80 | 112 | 1.5 |

| AT-AB-ZC6313CE | 6313CE | 65 | 140 | 33 | 2.1 | 76 | 85.5 | 129 | 2 |

| AT-AB-ZC6814CE | 6814CE | 70 | 90 | 10 | 0.6 | 74 | 74.5 | 86 | 0.6 |

| AT-AB-ZC6914CE | 6914CE | 70 | 100 | 16 | 1 | 75 | 77.5 | 95 | 1 |

| AT-AB-ZC16014CE | 16014CE | 70 | 110 | 13 | 0.6 | 74 | / | 106 | 0.6 |

| AT-AB-ZC6014CE | 6014CE | 70 | 110 | 20 | 1.1 | 76.5 | 80.5 | 103.5 | 1 |

| AT-AB-ZC6214CE | 6214CE | 70 | 125 | 24 | 1.5 | 78 | 84 | 117 | 1.5 |

| AT-AB-ZC6314CE | 6314CE | 70 | 150 | 35 | 2.1 | 81 | 92 | 139 | 2 |

| AT-AB-ZC6815CE | 6815CE | 75 | 95 | 10 | 0.6 | 79 | 79.5 | 91 | 0.6 |

| AT-AB-ZC6915CE | 6915CE | 75 | 105 | 16 | 1 | 80 | 82 | 100 | 1 |

| AT-AB-ZC16015CE | 16015CE | 75 | 115 | 13 | 0.6 | 79 | / | 111 | 0.6 |

| AT-AB-ZC6015CE | 6015CE | 75 | 115 | 20 | 1.1 | 81.5 | 85.5 | 108.5 | 1 |

| AT-AB-ZC6215CE | 6215CE | 75 | 130 | 25 | 1.5 | 83 | 90 | 122 | 1.5 |

| AT-AB-ZC6816CE | 6816CE | 80 | 100 | 10 | 0.6 | 84 | 84.5 | 96 | 0.6 |

| AT-AB-ZC6916CE | 6916CE | 80 | 110 | 16 | 1 | 85 | 87.5 | 105 | 1 |

| AT-AB-ZC16016CE | 16016CE | 80 | 125 | 14 | 0.6 | 84 | / | 121 | 0.6 |

| AT-AB-ZC6016CE | 6016CE | 80 | 125 | 22 | 1.1 | 86.5 | 91 | 118.5 | 1 |

| AT-AB-ZC6216CE | 6216CE | 80 | 140 | 26 | 2 | 89 | 95.5 | 131 | 2 |

| AT-AB-ZC6817CE | 6817CE | 85 | 110 | 13 | 1 | 90 | 90.5 | 105 | 1 |

| AT-AB-ZC6917CE | 6917CE | 85 | 120 | 18 | 1.1 | 91.5 | 94.5 | 113.5 | 1 |

| AT-AB-ZC16017CE | 16017CE | 85 | 130 | 14 | 0.6 | 89 | / | 126 | 0.6 |

| AT-AB-ZC6017CE | 6017CE | 85 | 130 | 22 | 1.1 | 91.5 | 96 | 123.5 | 1 |

| AT-AB-ZC6217CE | 6217CE | 85 | 150 | 28 | 2 | 94 | 102 | 141 | 2 |

| AT-AB-ZC6818CE | 6818CE | 90 | 115 | 13 | 1 | 95 | 95.5 | 110 | 1 |

| AT-AB-ZC6918CE | 6918CE | 90 | 125 | 18 | 1.1 | 96.5 | 98.5 | 118.5 | 1 |

| AT-AB-ZC16018CE | 16018CE | 90 | 140 | 16 | 1 | 95 | / | 135 | 1 |

| AT-AB-ZC6018CE | 6018CE | 90 | 140 | 24 | 1.5 | 98 | 103 | 132 | 1.5 |

| AT-AB-ZC6819CE | 6819CE | 95 | 120 | 13 | 1 | 100 | 102 | 115 | 1 |

| AT-AB-ZC6919CE | 6919CE | 95 | 130 | 18 | 1.1 | 101.5 | 104 | 123.5 | 1 |

| AT-AB-ZC16019CE | 16019CE | 95 | 145 | 16 | 1 | 100 | / | 140 | 1 |

| AT-AB-ZC6019CE | 6019CE | 95 | 145 | 24 | 1.5 | 103 | 109 | 137 | 1.5 |

| AT-AB-ZC6820CE | 6820CE | 100 | 125 | 13 | 1 | 105 | 106 | 120 | 1 |

| AT-AB-ZC6920CE | 6920CE | 100 | 140 | 20 | 1.1 | 106.5 | 111 | 133.5 | 1 |

| AT-AB-ZC16020CE | 16020CE | 100 | 150 | 16 | 1 | 105 | / | 145 | 1 |

| AT-AB-ZC6020CE | 6020CE | 100 | 150 | 24 | 1.5 | 108 | 113 | 142 | 1.5 |

| AT-AB-ZC6821CE | 6821CE | 105 | 130 | 13 | 1 | 110 | 111 | 125 | 1 |

| AT-AB-ZC6921CE | 6921CE | 105 | 145 | 20 | 1.1 | 111.5 | 116 | 138.5 | 1 |

| AT-AB-ZC6822CE | 6822CE | 110 | 140 | 16 | 1 | 115 | 117 | 135 | 1 |

| AT-AB-ZC6922CE | 6922CE | 110 | 150 | 20 | 1.1 | 116.5 | 121 | 143.5 | 1 |

| AT-AB-ZC6824CE | 6824CE | 120 | 150 | 16 | 1 | 125 | 127 | 145 | 1 |

| AT-AB-ZC6924 | 6924 | 120 | 165 | 22 | 1.1 | / | / | / | / |

| AT-AB-ZC16024 | 16024 | 120 | 180 | 19 | 1 | / | / | / | / |

| AT-AB-ZC6024 | 6024 | 120 | 180 | 28 | 2 | / | / | / | / |

| AT-AB-ZC6224 | 6224 | 120 | 215 | 40 | 2.1 | / | / | / | / |

| AT-AB-ZC6324 | 6324 | 120 | 260 | 55 | 3 | / | / | / | / |

| AT-AB-ZC6826 | 6826 | 130 | 165 | 18 | 1.1 | / | / | / | / |

| AT-AB-ZC6926 | 6926 | 130 | 180 | 24 | 1.5 | / | / | / | / |

| AT-AB-ZC16026 | 16026 | 130 | 200 | 22 | 1.1 | / | / | / | / |

| AT-AB-ZC6026 | 6026 | 130 | 200 | 33 | 2 | / | / | / | / |

| AT-AB-ZC6226 | 6226 | 130 | 230 | 40 | 3 | / | / | / | / |

| AT-AB-ZC6326 | 6326 | 130 | 280 | 58 | 4 | / | / | / | / |

| AT-AB-ZC6828 | 6828 | 140 | 175 | 18 | 1.1 | / | / | / | / |

| AT-AB-ZC6928 | 6928 | 140 | 190 | 24 | 1.5 | / | / | / | / |

| AT-AB-ZC16028 | 16028 | 140 | 210 | 22 | 1.1 | / | / | / | / |

| AT-AB-ZC6028 | 6028 | 140 | 210 | 33 | 2 | / | / | / | / |

| AT-AB-ZC6228 | 6228 | 140 | 250 | 42 | 3 | / | / | / | / |

| AT-AB-ZC6328 | 6328 | 140 | 300 | 62 | 4 | / | / | / | / |

| AT-AB-ZC6830 | 6830 | 150 | 190 | 20 | 1.1 | / | / | / | / |

| AT-AB-ZC6930 | 6930 | 150 | 210 | 28 | 2 | / | / | / | / |

| AT-AB-ZC16030 | 16030 | 150 | 225 | 24 | 1.1 | / | / | / | / |

| AT-AB-ZC6030 | 6030 | 150 | 225 | 35 | 2.1 | / | / | / | / |

| AT-AB-ZC6230 | 6230 | 150 | 270 | 45 | 3 | / | / | / | / |

| AT-AB-ZC6330 | 6330 | 150 | 320 | 65 | 4 | / | / | / | / |

| AT-AB-ZC60/22 | 60/22 | 22 | 44 | 12 | 0.6 | / | / | / | / |

| AT-AB-ZC62/22 | 62/22 | 22 | 50 | 14 | 1 | / | / | / | / |

| AT-AB-ZC63/22 | 63/22 | 22 | 56 | 16 | 1.1 | / | / | / | / |

| AT-AB-ZC60/28 | 60/28 | 28 | 52 | 12 | 0.6 | / | / | / | / |

| AT-AB-ZC62/28 | 62/28 | 28 | 58 | 16 | 1 | / | / | / | / |

| AT-AB-ZC63/28 | 63/28 | 28 | 68 | 18 | 1.1 | / | / | / | / |

| AT-AB-ZC60/32 | 60/32 | 33 | 58 | 13 | 1 | / | / | / | / |

| AT-AB-ZC62/32 | 62/32 | 33 | 65 | 17 | 1 | / | / | / | / |

| AT-AB-ZC63/32 | 63/32 | 33 | 75 | 20 | 1.1 | / | / | / | / |

| AT-AB-ZC603CE | 603CE | 3 | 9 | 3 | / | / | / | / | / |

| AT-AB-ZC606CE | 606CE | 6 | 17 | 6 | / | / | / | / | / |

| AT-AB-ZCMR117 | MR117 | 7 | 11 | 3 | / | / | / | / | / |

| AT-AB-ZCMR128 | MR128 | 8 | 12 | 3.5 | / | / | / | / | / |

| AT-AB-ZCMR85 | MR85 | 5 | 8 | 2.5 | / | / | / | / | / |

| AT-AB-ZCMR63-1 | MR63-1 | 3 | 6 | 2.5 | / | / | / | / | / |

| AT-AB-ZCMR85-1 | MR85-1 | 5 | 8 | 2 | / | / | / | / | / |

| AT-AB-ZCMR148 | MR148 | 8 | 14 | 4 | / | / | / | / | / |

| AT-AB-ZCMR84 | MR84 | 4 | 8 | 2 | / | / | / | / | / |

| AT-AB-ZCMR126 | MR126 | 6 | 12 | 4 | / | / | / | / | / |

| AT-AB-ZCMR74-1 | MR74-1 | 4 | 7 | 2 | / | / | / | / | / |

| AT-AB-ZCMR84-1 | MR84-1 | 4 | 8 | 3 | / | / | / | / | / |

| AT-AB-ZCMR74 | MR74 | 4 | 7 | 2.5 | / | / | / | / | / |

| AT-AB-ZCMR148 | MR148 | 8 | 14 | 3.5 | / | / | / | / | / |

| AT-AB-ZCMR63 | MR63 | 3 | 6 | 2 | / | / | / | / | / |

| AT-AB-ZCMR103 | MR103 | 3 | 10 | 4 | / | / | / | / | / |

| AT-AB-ZCMR104 | MR104 | 4 | 10 | 4 | / | / | / | / | / |

| AT-AB-ZCMR105 | MR105 | 5 | 10 | 3 | / | / | / | / | / |

| AT-AB-ZCMR105-1 | MR105-1 | 5 | 10 | 4 | / | / | / | / | / |

| AT-AB-ZCMR106 | MR106 | 6 | 10 | 2.5 | / | / | / | / | / |

| AT-AB-ZCMR106-1 | MR106-1 | 6 | 10 | 3 | / | / | / | / | / |

| AT-AB-ZCMR115 | MR115 | 5 | 11 | 4 | / | / | / | / | / |

| AT-AB-ZCMR52 | MR52 | 2 | 5 | 2.5 | / | / | / | / | / |

| AT-AB-ZCMR62 | MR62 | 2 | 6 | 2.5 | / | / | / | / | / |

| AT-AB-ZCMR94 | MR94 | 4 | 9 | 3 | / | / | / | / | / |

| AT-AB-ZCMR95 | MR95 | 5 | 9 | 3 | / | / | / | / | / |

| AT-AB-ZCR188 | R188 | 6.35 | 12.7 | 4.763 | / | / | / | / | / |

| AT-AB-ZCR6 | R6 | 9.525 | 22.225 | 5.556 | / | / | / | / | / |

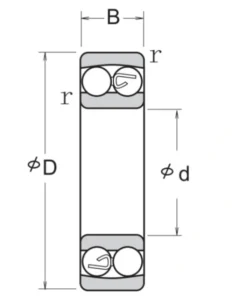

| Alumina Bearing | ||||

| Item NO. | Model | Product Size (mm) | ||

| d(Inner Dia) | D(Outer Dia) | B(Height) | ||

| AT-AB-ZC135 | 135 | 6 | 19 | 6 |

| AT-AB-ZC126 | 126 | 6 | 19 | 6 |

| AT-AB-ZC127 | 127 | 7 | 22 | 7 |

| AT-AB-ZC108 | 108 | 8 | 22 | 7 |

| AT-AB-ZC129 | 129 | 9 | 26 | 8 |

| AT-AB-ZC1200 | 1200 | 10 | 30 | 9 |

| AT-AB-ZC2200 | 2200 | 10 | 30 | 14 |

| AT-AB-ZC1300 | 1300 | 10 | 25 | 11 |

| AT-AB-ZC2300 | 2300 | 10 | 25 | 17 |

| AT-AB-ZC1201 | 1201 | 12 | 32 | 10 |

| AT-AB-ZC2201 | 2201 | 12 | 32 | 14 |

| AT-AB-ZC1301 | 1301 | 12 | 37 | 12 |

| AT-AB-ZC2301 | 2301 | 12 | 37 | 17 |

| AT-AB-ZC1202 | 1202 | 15 | 11 | 11 |

| AT-AB-ZC2202 | 2202 | 15 | 14 | 14 |

| AT-AB-ZC1302 | 1302 | 15 | 13 | 13 |

| AT-AB-ZC2302 | 2302 | 15 | 17 | 17 |

| AT-AB-ZC1203 | 1203 | 17 | 12 | 12 |

| AT-AB-ZC2203 | 2203 | 17 | 16 | 16 |

| AT-AB-ZC1303 | 1303 | 17 | 14 | 14 |

| AT-AB-ZC2303 | 2303 | 17 | 19 | 19 |

| AT-AB-ZC7908 | 7908 | 40 | 62 | 12 |

| AT-AB-ZC7008 | 7008 | 40 | 68 | 15 |

| AT-AB-ZC7208 | 7208 | 40 | 80 | 18 |

| AT-AB-ZC7308 | 7308 | 40 | 90 | 23 |

| AT-AB-ZC7909 | 7909 | 45 | 68 | 12 |

| AT-AB-ZC7009 | 7009 | 45 | 75 | 16 |

| AT-AB-ZC7209 | 7209 | 45 | 85 | 19 |

| AT-AB-ZC7309 | 7309 | 45 | 100 | 25 |

| AT-AB-ZC7910 | 7910 | 50 | 72 | 123 |

| AT-AB-ZC7010 | 7010 | 50 | 80 | 16 |

| AT-AB-ZC7210 | 7210 | 50 | 90 | 20 |

| AT-AB-ZC7310 | 7310 | 50 | 110 | 27 |

| AT-AB-ZC7911 | 7911 | 55 | 80 | 13 |

| AT-AB-ZC7011 | 7011 | 55 | 90 | 18 |

| AT-AB-ZC7211 | 7211 | 55 | 100 | 21 |

| AT-AB-ZC7311 | 7311 | 55 | 120 | 29 |

| AT-AB-ZC7912 | 7912 | 60 | 85 | 13 |

| AT-AB-ZC7012 | 7012 | 60 | 95 | 18 |

| AT-AB-ZC7212 | 7212 | 60 | 110 | 22 |

| AT-AB-ZC7312 | 7312 | 60 | 130 | 31 |

| AT-AB-ZC7913 | 7913 | 65 | 90 | 13 |

| AT-AB-ZC7013 | 7013 | 65 | 100 | 18 |

| AT-AB-ZC7213 | 7213 | 65 | 120 | 23 |

| AT-AB-ZC7313 | 7313 | 65 | 140 | 33 |

| AT-AB-ZC7914 | 7914 | 70 | 100 | 16 |

| AT-AB-ZC7014 | 7014 | 70 | 110 | 20 |

| AT-AB-ZC7214 | 7214 | 70 | 125 | 24 |

| AT-AB-ZC7314 | 7314 | 70 | 150 | 35 |

| AT-AB-ZC7915 | 7915 | 75 | 105 | 16 |

| AT-AB-ZC7015 | 7015 | 75 | 115 | 20 |

| AT-AB-ZC7215 | 7215 | 75 | 130 | 25 |

| AT-AB-ZC7916 | 7916 | 80 | 110 | 16 |

| AT-AB-ZC7016 | 7016 | 80 | 125 | 22 |

| AT-AB-ZC7216 | 7216 | 80 | 140 | 26 |

| AT-AB-ZC7017 | 7017 | 85 | 130 | 22 |

| AT-AB-ZC7217 | 7217 | 85 | 150 | 28 |

| AT-AB-ZC7918 | 7918 | 90 | 125 | 18 |

| AT-AB-ZC7018 | 7018 | 90 | 140 | 24 |

| AT-AB-ZC7919 | 7919 | 95 | 130 | 18 |

| AT-AB-ZC7019 | 7019 | 95 | 145 | 24 |

| AT-AB-ZC7920 | 7920 | 100 | 140 | 20 |

| AT-AB-ZC7020 | 7020 | 100 | 150 | 24 |

| AT-AB-ZC7921 | 7921 | / | 145 | 20 |

| AT-AB-ZC7922 | 7922 | / | 150 | 20 |

| AT-AB-ZC2312 | 2312 | 60 | 130 | 46 |

| AT-AB-ZC1213 | 1213 | 65 | 120 | 23 |

| AT-AB-ZC2213 | 2213 | 120 | 31 | |

| AT-AB-ZC1313 | 1313 | 14 | 33 | |

| AT-AB-ZC2313 | 2313 | 140 | 48 | |

| AT-AB-ZC1214 | 1214 | 70 | 125 | 24 |

| AT-AB-ZC2214 | 2214 | 125 | 31 | |

| AT-AB-ZC1314 | 1314 | 150 | 35 | |

| AT-AB-ZC2314 | 2314 | 150 | 51 | |

| AT-AB-ZC1215 | 1215 | 75 | 130 | 25 |

| AT-AB-ZC2215 | 2215 | 130 | 31 | |

| AT-AB-ZC1315 | 1315 | 160 | 37 | |

| AT-AB-ZC2315 | 2315 | 160 | 55 | |

| AT-AB-ZC1216 | 1216 | 80 | 140 | 26 |

| AT-AB-ZC2216 | 2216 | 140 | 33 | |

| AT-AB-ZC1316 | 1316 | 170 | 39 | |

| AT-AB-ZC2316 | 2316 | 170 | 58 | |

| AT-AB-ZC1217 | 1217 | 85 | 150 | 28 |

| AT-AB-ZC2217 | 2217 | 150 | 36 | |

| AT-AB-ZC1317 | 1317 | 180 | 41 | |

| AT-AB-ZC2317 | 2317 | 180 | 60 | |

| AT-AB-ZC1218 | 1218 | 90 | 160 | 30 |

| AT-AB-ZC2218 | 2218 | 160 | 40 | |

| AT-AB-ZC1318 | 1318 | 190 | 43 | |

| AT-AB-ZC2318 | 2318 | 190 | 64 | |

| AT-AB-ZC1219 | 1219 | 95 | 170 | 32 |

| AT-AB-ZC2219 | 2219 | 170 | 43 | |

| AT-AB-ZC1319 | 1319 | 200 | 45 | |

| AT-AB-ZC2319 | 2319 | 200 | 67 | |

| AT-AB-ZC1220 | 1220 | 100 | 180 | 34 |

| AT-AB-ZC2220 | 2220 | 180 | 46 | |

| AT-AB-ZC1221 | 1221 | 105 | 190 | 36 |

| AT-AB-ZC2221 | 2221 | 190 | 50 | |

| AT-AB-ZC1222 | 1222 | 110 | 200 | 38 |

| AT-AB-ZC2222 | 2222 | 200 | 53 | |

| AT-AB-ZC1204 | 1204 | 20 | 47 | 14 |

| AT-AB-ZC2204 | 2204 | 47 | 18 | |

| AT-AB-ZC1304 | 1304 | 52 | 15 | |

| AT-AB-ZC2304 | 2304 | 52 | 21 | |

| AT-AB-ZC1205 | 1205 | 25 | 52 | 15 |

| AT-AB-ZC2205 | 2205 | 52 | 18 | |

| AT-AB-ZC1305 | 1305 | 62 | 17 | |

| AT-AB-ZC2305 | 2305 | 62 | 24 | |

| AT-AB-ZC1206 | 1206 | 30 | 62 | 16 |

| AT-AB-ZC2206 | 2206 | 62 | 20 | |

| AT-AB-ZC1306 | 1306 | 72 | 19 | |

| AT-AB-ZC2306 | 2306 | 72 | 27 | |

| AT-AB-ZC1207 | 1207 | 35 | 72 | 17 |

| AT-AB-ZC2207 | 2207 | 72 | 23 | |

| AT-AB-ZC1307 | 1307 | 80 | 21 | |

| AT-AB-ZC2307 | 2307 | 80 | 31 | |

| AT-AB-ZC1208 | 1208 | 40 | 80 | 18 |

| AT-AB-ZC2208 | 2208 | 80 | 23 | |

| AT-AB-ZC1308 | 1308 | 90 | 23 | |

| AT-AB-ZC2308 | 2308 | 90 | 33 | |

| AT-AB-ZC1209 | 1209 | 45 | 85 | 19 |

| AT-AB-ZC2209 | 2209 | 85 | 23 | |

| AT-AB-ZC1309 | 1309 | 100 | 25 | |

| AT-AB-ZC2309 | 2309 | 100 | 36 | |

| AT-AB-ZC1210 | 1210 | 50 | 90 | 20 |

| AT-AB-ZC2210 | 2210 | 90 | 23 | |

| AT-AB-ZC1310 | 1310 | 110 | 27 | |

| AT-AB-ZC2310 | 2310 | 110 | 40 | |

| AT-AB-ZC1211 | 1211 | 55 | 100 | 21 |

| AT-AB-ZC2211 | 2211 | 100 | 25 | |

| AT-AB-ZC1311 | 1311 | 120 | 29 | |

| AT-AB-ZC2311 | 2311 | 120 | 43 | |

| AT-AB-ZC1212 | 1212 | 60 | 110 | 22 |

| AT-AB-ZC2212 | 2212 | 110 | 28 | |

| AT-AB-ZC1312 | 1312 | 130 | 31 | |

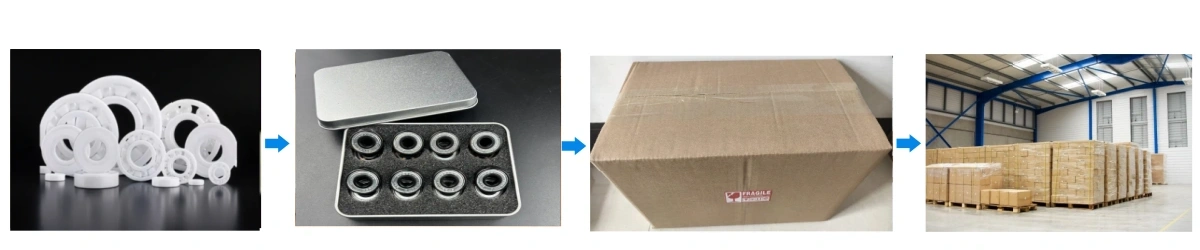

Alumina Ceramic Ball Bearings Packaging

- Alumina bearing balls are first packed in sealed inner plastic bags or vials to prevent dust contamination, then placed in small cartons with cushioning for transport.