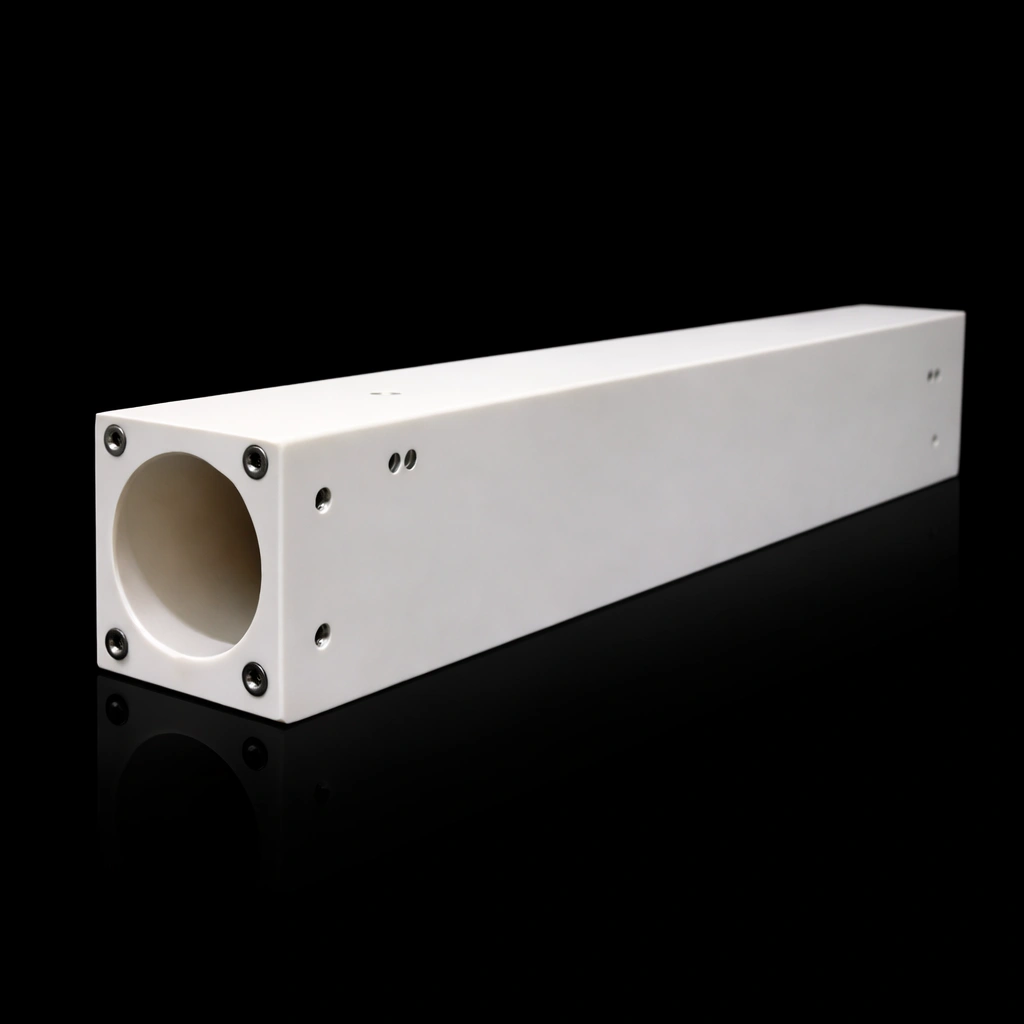

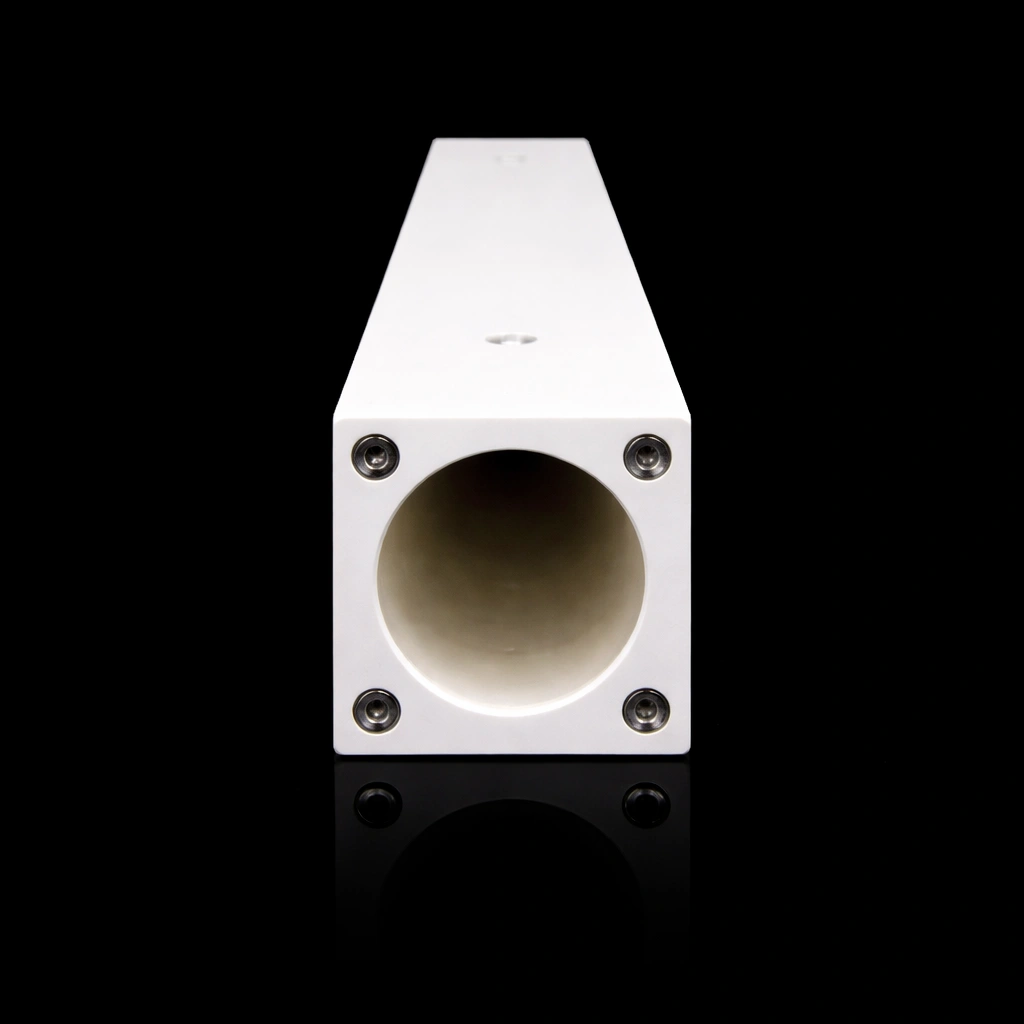

An Alumina Ceramic Air Bearing Guide Rail is a precision-ground alumina (Al₂O₃) rail used as the running surface for an aerostatic linear guide. With compressed air, the carriage floats on an air film, enabling near-frictionless, non-contact straight-line motion.

Alumina Ceramic Air Bearing Guide Rail Benefits

-

Defined datum strategy: reference faces and mounting faces can be controlled as a datum set for easier assembly alignment.

-

Stable running surface: ground/finished bearing face supports consistent air film behaviour when air quality is maintained.

-

Non-lube reference option: chosen when oil/grease cannot be tolerated near metrology optics, sensors, or clean work zones.

-

Geometry repeatability for series builds: supports multi-unit builds where the same rail geometry is reused across platforms.

-

Interface-ready designs: rails can be produced with single-hole or multi-hole patterns, slots, pockets, and end details for fixtures.

Alumina Ceramic Air Bearing Guide Rail Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

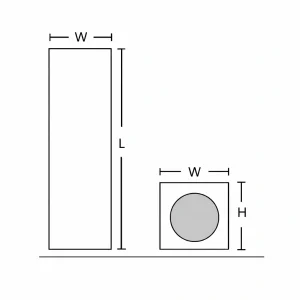

Alumina Ceramic Air Bearing Guide Rail Specifications

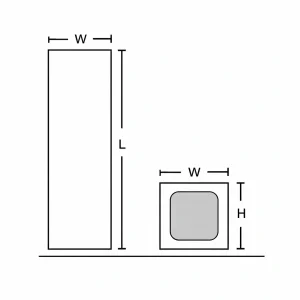

Type1 :

| Model | Size (W×H×L)mm | Flatness (μm) | Parallelism (μm) | Verticality | Weight (kg) |

| AT0646490-S | 64×64×90 | 6 | 3 | 2 | 6 |

| AT0686899-S | 68×68×99 | 10.6 | 10.6 | ||

| AT0707010-S | 70×70×1200 | 8.4 | 8.4 | ||

| AT0707012-S | 70×70×1400 | 12.6 | 12.6 | ||

| AT0808012-S | 80×80×1200 | 17.6 | 17.6 | ||

| AT0808014-S | 80×80×1400 | 17.6 | 17.6 |

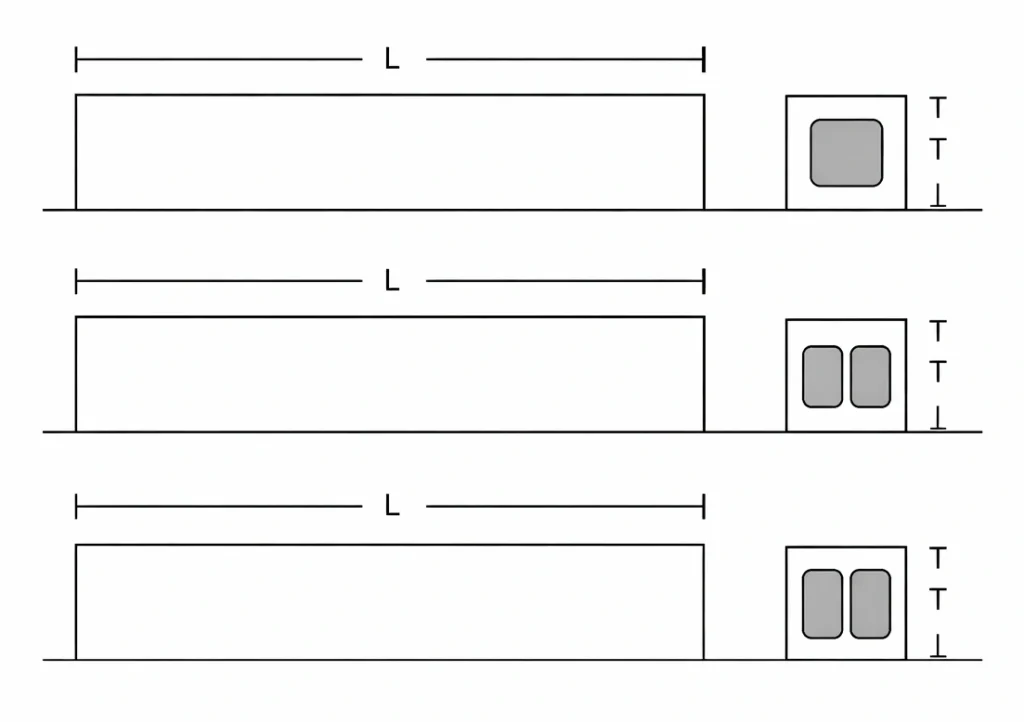

Type2 :

| No. | Size (W × H × L) | Flatness (µm) | Parallelism (µm) | Verticality (µm) | Weight (kg) |

| AT1020211-B | 200 × 120 × 1100 | 3 | 3 | 3 | 39 |

| AT1020215-B | 200 × 120 × 1550 | 3 | 3 | 3 | 56 |

| AT1216013-B | 165 × 100 × 1300 | 3 | 3 | 3 | 45 |

| AT3221015-B | 220 × 100 × 1500 | 3 | 3 | 3 | 55 |

| AT33717220-B | 375 × 120 × 2000 | 3 | 3 | 3 | 150 |

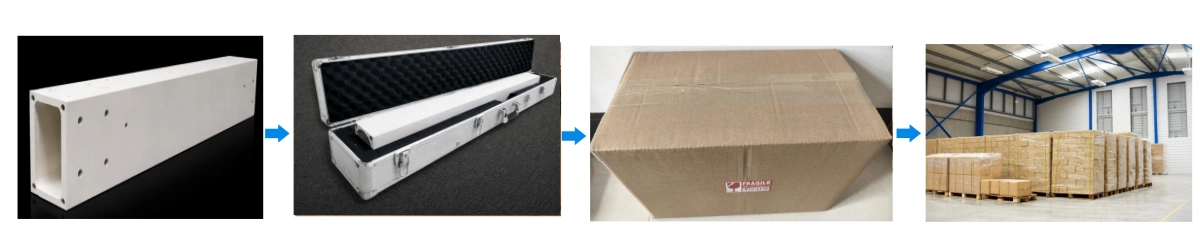

Alumina Ceramic Air Bearing Guide Rail Packaging

- Individual rail protection with bearing-face cover film or protective sheet to prevent scratches

- Edge guards on corners and ends to reduce chipping risk during handling