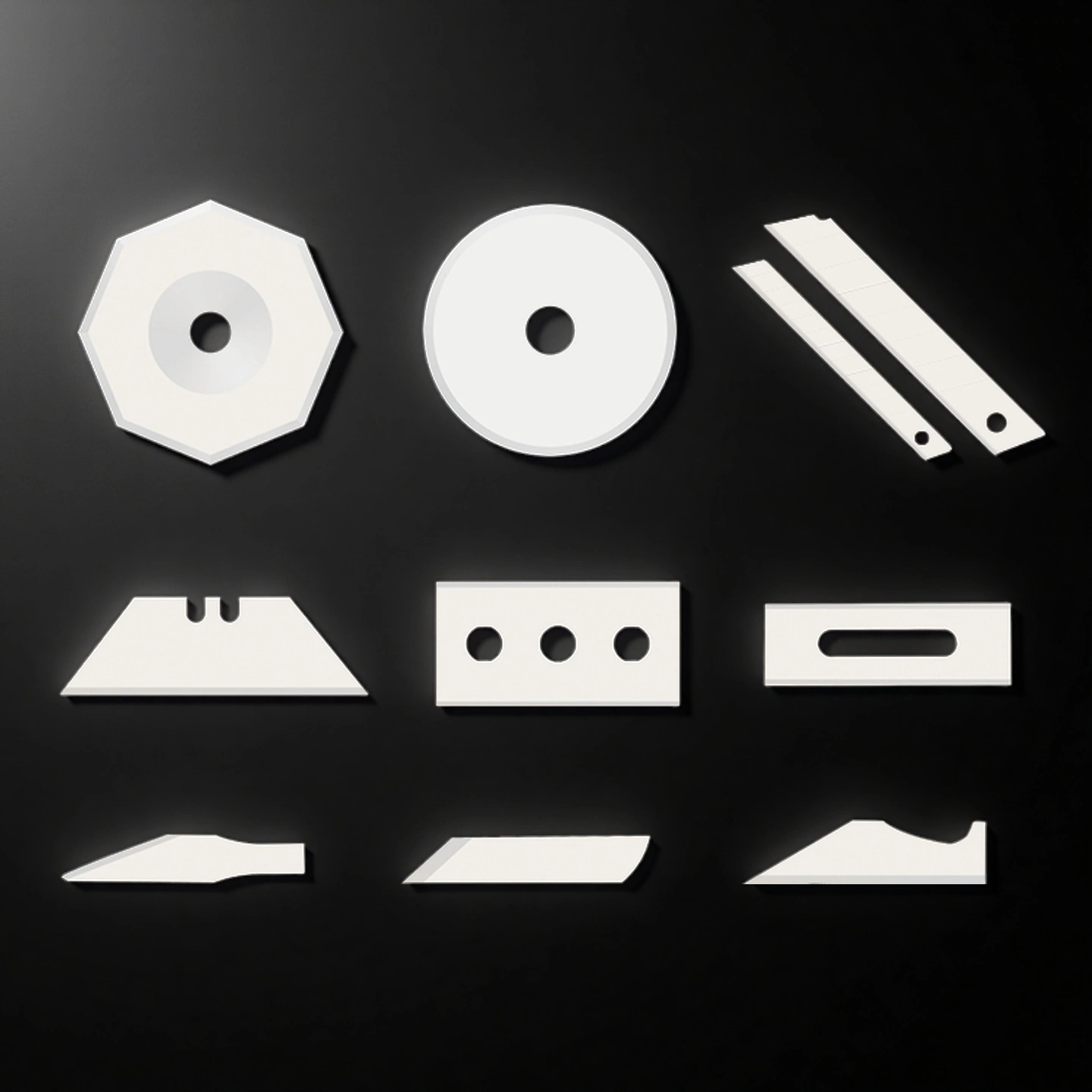

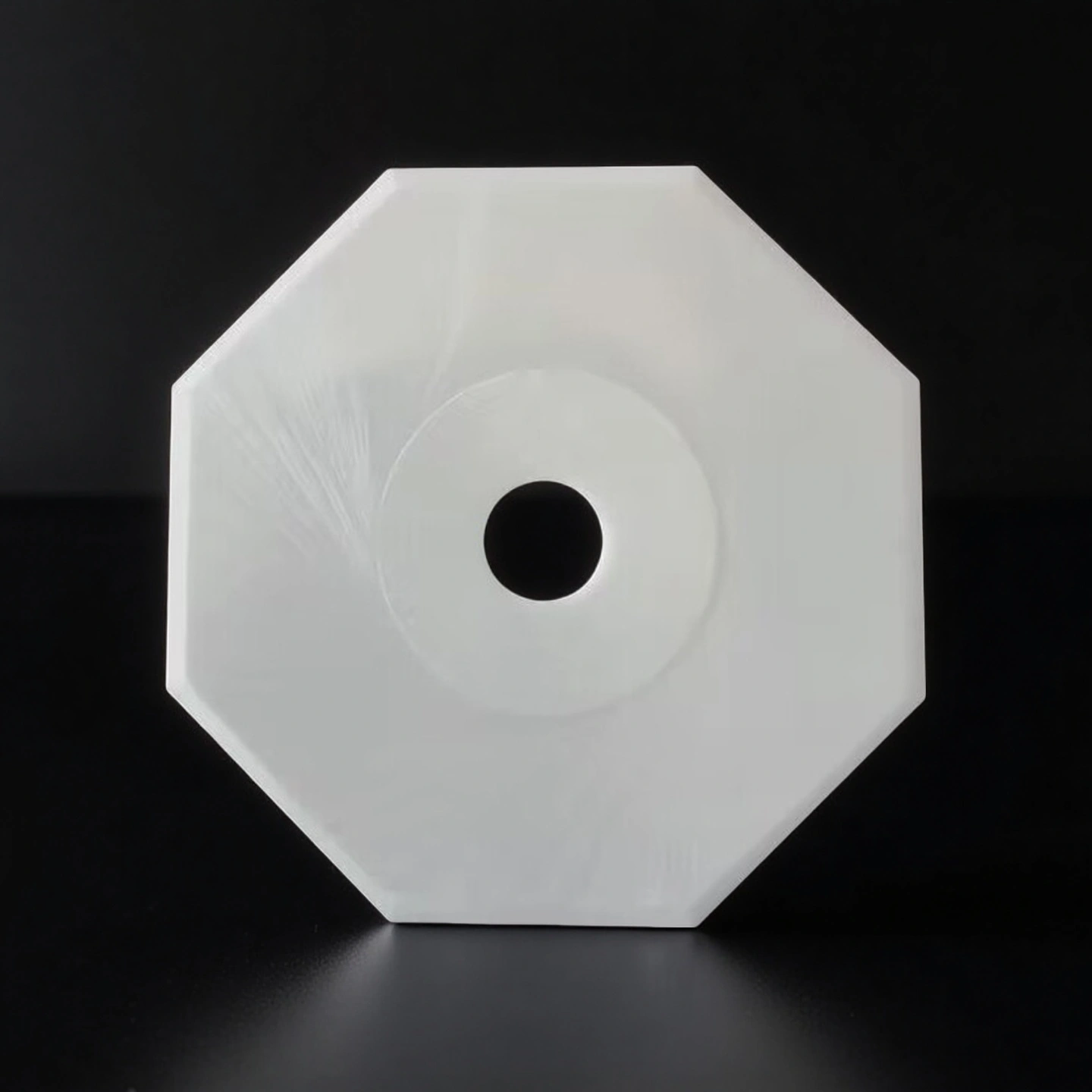

Made of technical-grade alumina ceramic, this blade is specifically designed for processing fiber, film, and composite materials. It offers high wear resistance, thermal stability, and a non-metallic, clean-cutting surface suitable for use across food processing, electronics, and textile machinery.

Alumina Ceramic Blade Benefits

-

Extremely High Wear Resistance

The ultrafine-grain alumina ceramic blade has very high hardness and abrasion resistance. Under appropriate cutting conditions, its service life can reach more than ten times that of carbide blades and more than one hundred times that of high-speed steel blades, which significantly reduces blade change frequency and saves cutting costs. -

Wide Chemical Corrosion Resistance

Alumina ceramic cutting blades show excellent stability when in contact with acids, alkalis, salts and many chemical reagents, so they can work directly in corrosive environments without corrosion risk and without contaminating the workpiece. -

High-Temperature Capability

Alumina ceramic blades can be used at very high temperature, with maximum application temperature reaching above 1500°C in suitable designs. This allows dry cutting or hot cutting of specific nonmetal materials in thermal or high-temperature processes. -

Non-Magnetic and Electrically Insulating

Alumina ceramic blades are non-conductive and non-magnetic. The smooth surface does not attract fine dust or particles easily, which is helpful in applications where magnetic fields, stray currents or particle adsorption must be minimized. -

Chemical and Biological Inertness

Alumina ceramic material is chemically inert and does not react with most cutting targets. It does not release metallic ions and has good biocompatibility, so it can be used in medical device manufacturing, biopharmaceutical processing and food-related cutting zones where clean surfaces are required.

Al2O3 Ceramic Blade Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Blade Specifications

| Alumina Ceramic Blade | ||

| Item No. | Diameter (mm) | Thickness (mm) |

| AT-YHA-CMB01 | Customize | |

Alumina Ceramic Blade Packaging

- The alumina ceramic blade is individually protected in soft material or a molded tray to prevent edge chipping and surface damage during transport.