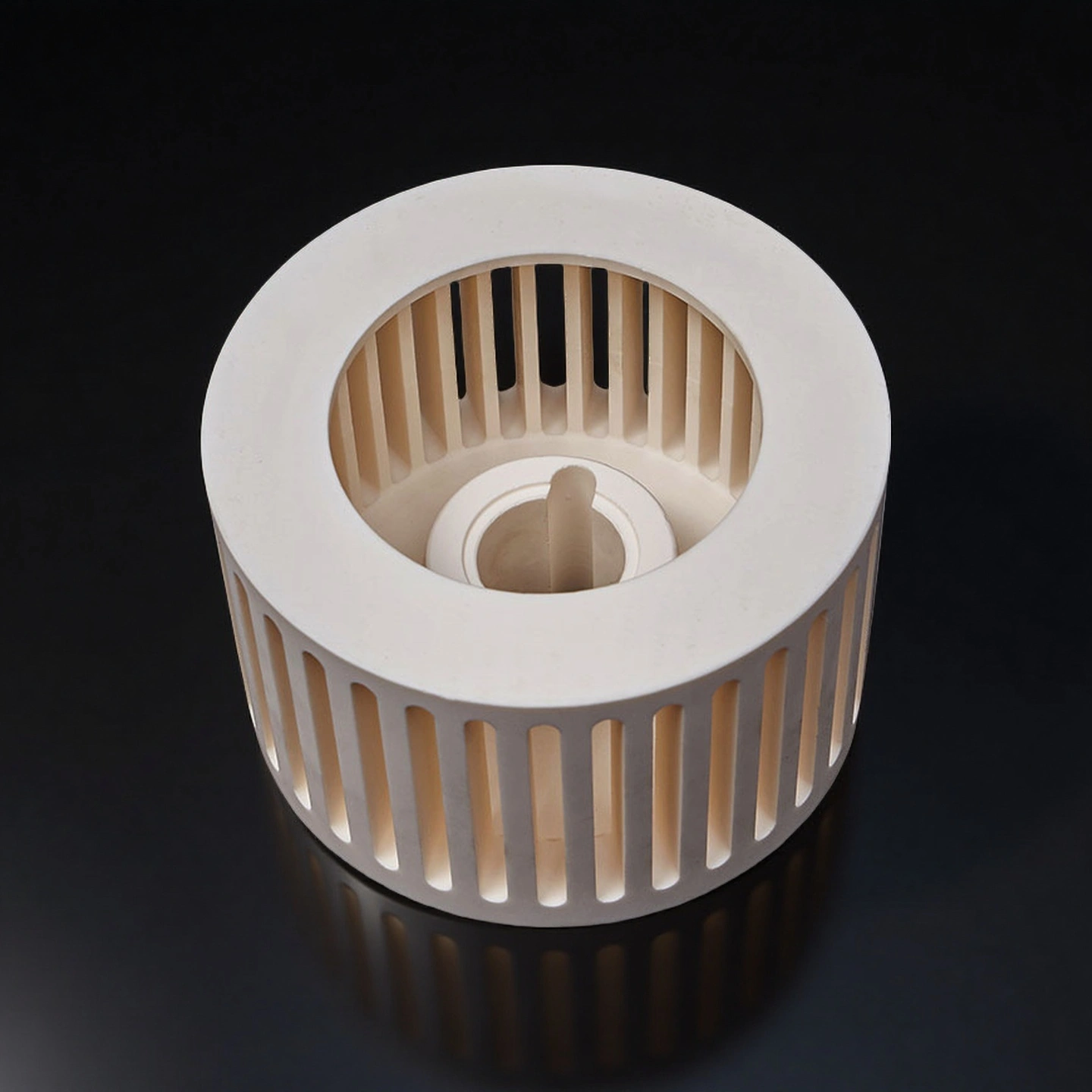

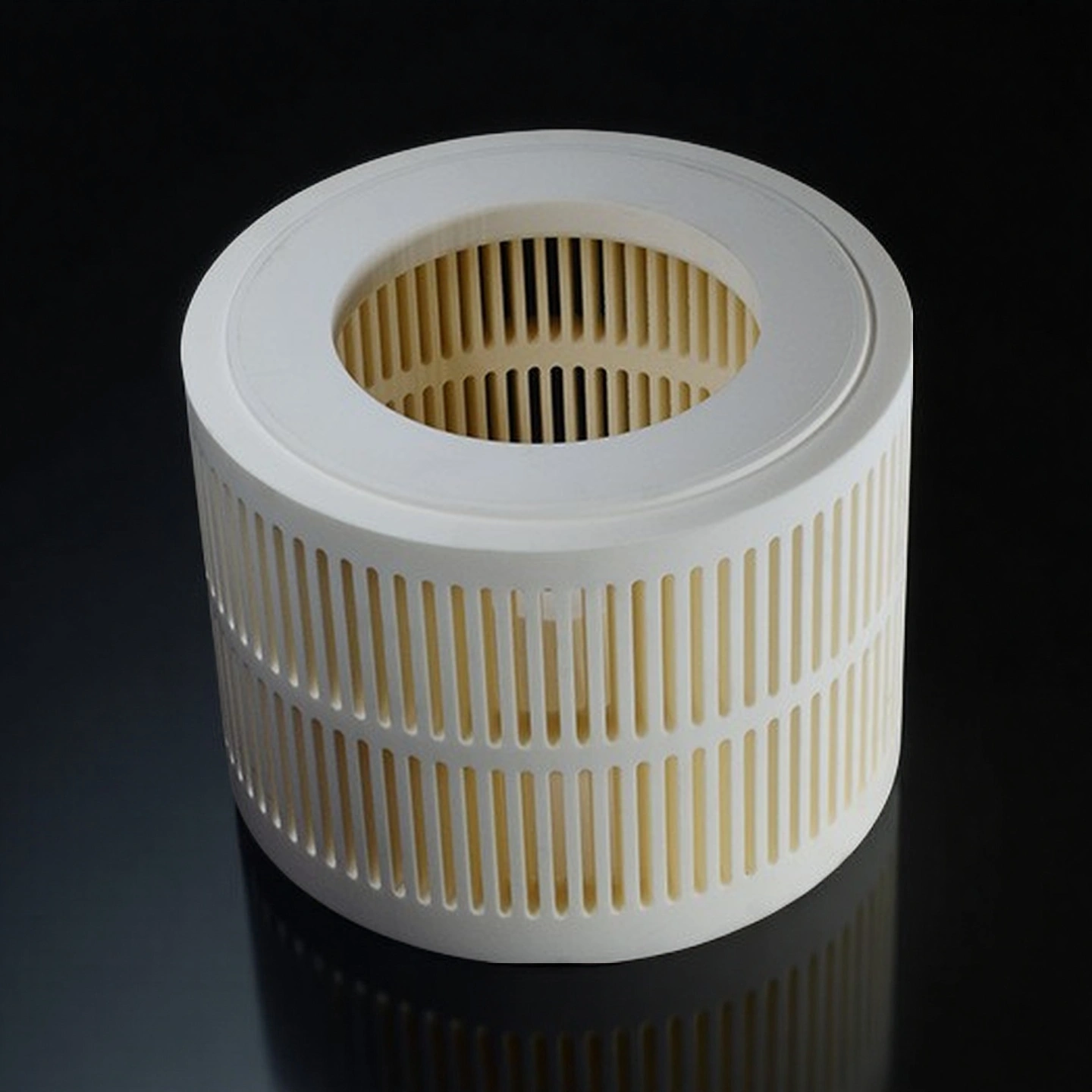

Alumina Ceramic Classifier Wheel is a high-purity Al₂O₃ ceramic rotating separation component used in air classifiers, jet mills and sand mills to precisely separate fine and coarse powders, ensuring stable particle size control, high wear resistance and low metal contamination in mining, metallurgy, chemical and energy material processing.

Alumina Ceramic Classifier Wheel Benefits

-

Precision cut size control in air classifier systems

The ceramic classifier wheel works with the air flow field to generate a stable separation zone, enabling fine powder cuts (often D97 below 10–20 µm depending on the mill design and speed) with narrow particle size distributions. -

Wear-resistant alumina construction for abrasive powders

High-purity alumina ceramics combine high hardness and abrasion resistance, so the classifier wheel withstands continuous contact with hard minerals, pigments and ceramic powders that would rapidly wear metallic wheels. -

Metal-free powder flow path for contamination-sensitive products

Using an alumina ceramic classifier wheel eliminates direct metal contact in the classification zone, reducing Fe and Ni contamination in battery materials, advanced ceramics and high-purity chemical powders. -

Stable operation at high peripheral speed

Dense, high-strength alumina with controlled dimensional tolerances supports high rotational speeds used in dynamic air classifiers, maintaining balance and minimizing vibration in long-term operation. -

Compatible with different mills and classifier designs

The alumina ceramic classifier wheel can be engineered as a mono-bloc disc, ring-type wheel or integrated rotor assembly to suit horizontal or vertical air classifiers, jet mills and combined grinding–classification systems.

Alumina Classifier Wheel Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Ceramic Classifier Wheel Specifications

| Alumina Grading Wheel | ||||

| Item No. | Outer Diameter(mm) | Inner Diameter (mm) | Height (mm) | Purity |

| AT-SM-A001 | 50 | 30 | 70 | 95%-99% |

| AT-SM-A002 | 80 | 65 | 90 | 95%-99% |

| AT-SM-A003 | 100 | 75 | 80 | 95%-99% |

| AT-SM-A004 | 155 | 135 | 95 | 95%-99% |

| AT-SM-A005 | 250 | 220 | 100 | 95%-99% |

| AT-SM-A006 | 260 | 240 | 120 | 95%-99% |

Alumina Ceramic Classifier Wheel Packaging

- Each alumina ceramic classifier wheel is wrapped with soft cushioning material around the blades and bore to minimize impact and edge chipping during transit.