An Alumina Ceramic Boat with Hole is a high-temperature sample boat (tray) made from alumina ceramic that includes one or more holes in the body (or tail area). The hole is used to manage gas flow and venting during heating, so the sample heats more consistently and the process is easier to control in tube furnaces and combustion-style test setups.

Advantages of Alumina Ceramic Crucibles with a Hole

-

Hole-featured airflow control

The integrated hole is engineered to guide oxygen or process gas directly through the sample zone inside combustion tubes, reducing local oxygen deficiency and improving burn repeatability between runs. This structure helps stabilize reaction behavior when sample mass or composition varies. -

Combustion-specific geometry options

Tail-and-hole boat designs allow precise positioning within combustion tubes and analyzers, ensuring consistent insertion depth and orientation. This geometry minimizes sample displacement during loading and supports repeatable hot-zone exposure across operators and shifts. -

High-temperature capability for hole boats

Alumina ceramic boats with hole are specified for sustained operation at temperatures up to approximately 1650 °C, making them suitable for combustion analysis, ashing, and high-temperature sample preparation without structural deformation under routine thermal cycles. -

Wide dimensional coverage for method standardization

Available formats range from 50 × 5 × 5 mm micro boats to 300 × 40 × 30 mm long boats, allowing laboratories to standardize boat geometry across different test methods, furnace zones, and sample scales while keeping loading rules consistent. -

Published density reference for durability screening

A documented bulk density range, such as 3.6–3.93 g/cm³, is commonly used as a practical indicator of ceramic body compactness, helping users assess resistance to chipping, warping, and fatigue during repeated high-temperature combustion cycles.

Alumina Ceramic Boats with Hole Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

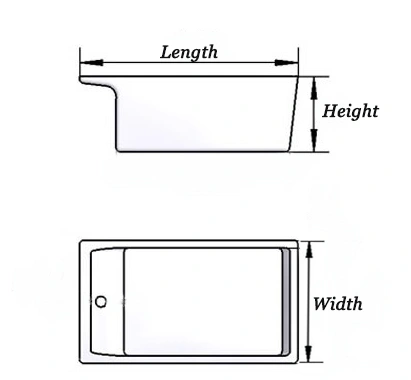

Alumina Crucibles with Hole Specifications

| Item NO. | length (mm) | width (mm) | height (mm) |

| TE-AS-071 | 100 | 84 | 35 |

| TE-AS-072 | 100 | 56 | 35 |

| TE-AS-073 | 100 | 43 | 26 |

| TE-AS-074 | 100 | 27 | 27 |

| TE-AS-075 | 100 | 24 | 17 |

| TE-AS-075-1 | 100 | 20 | 20 |

| TE-AS-075-2 | 100 | 27 | 27 |

| TE-AS-075-3 | 103 | 28 | 30 |

| TE-AS-075-4 | 100 | 43 | 25 |

| TE-AS-075-5 | 100 | 24 | 17 |

| TE-AS-075-6 | 100 | 27 | 25 |

| TE-AS-075-7 | 100 | 43 | 26 |

| TE-AS-075-8 | 100 | 56 | 35 |

| TE-AS-075-9 | 100 | 50 | 35 |

| TE-AS-075-10 | 100 | 56 | 35 |

| TE-AS-076 | 73 | 30 | 22 |

| TE-AS-076-1 | 73 | 30 | 22 |

| TE-AS-076-2 | 70 | 30 | 22 |

| TE-FA-001 | 300 | 70 | 30 |

| TE-FA-002 | 200 | 80 | 35 |

| TE-FA-003 | 200 | 11 | 12 |

| TE-FA-004 | 105 | 23 | 20 |

| TE-FA-005 | 100 | 30 | 25 |

| TE-FA-006 | 90 | 10 | 10 |

| TE-FA-007 | 80 | 30 | 20 |

| TE-FA-008 | 88 | 12 | 10 |

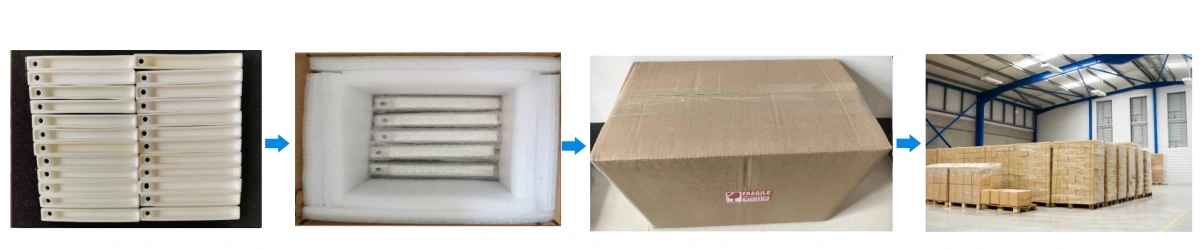

Alumina Boats with Hole Packaging

- Individual protection: each crucible and lid separated to prevent chipping during transit

- Foam + carton structure: rigid cushioning around rims and lids (common damage points)