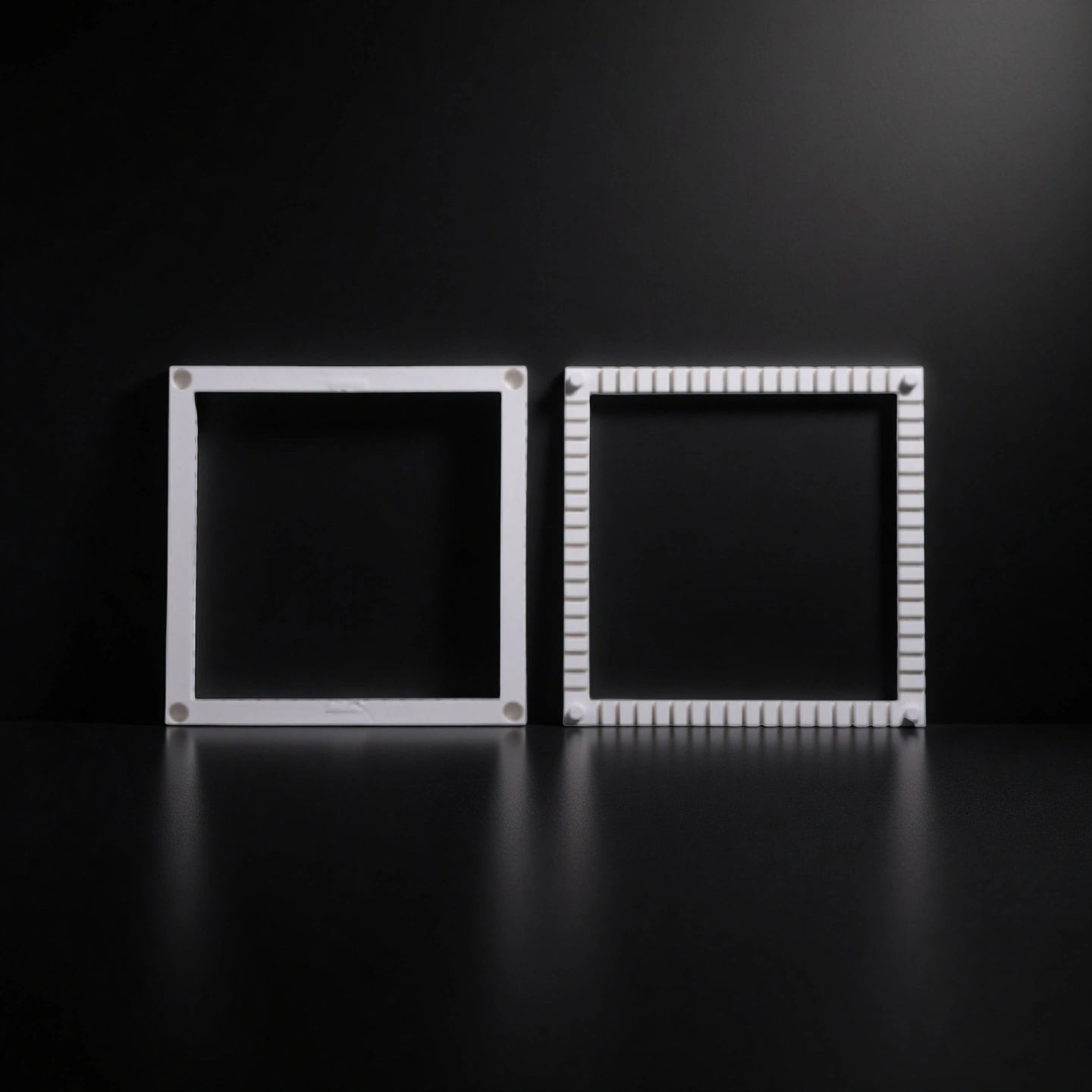

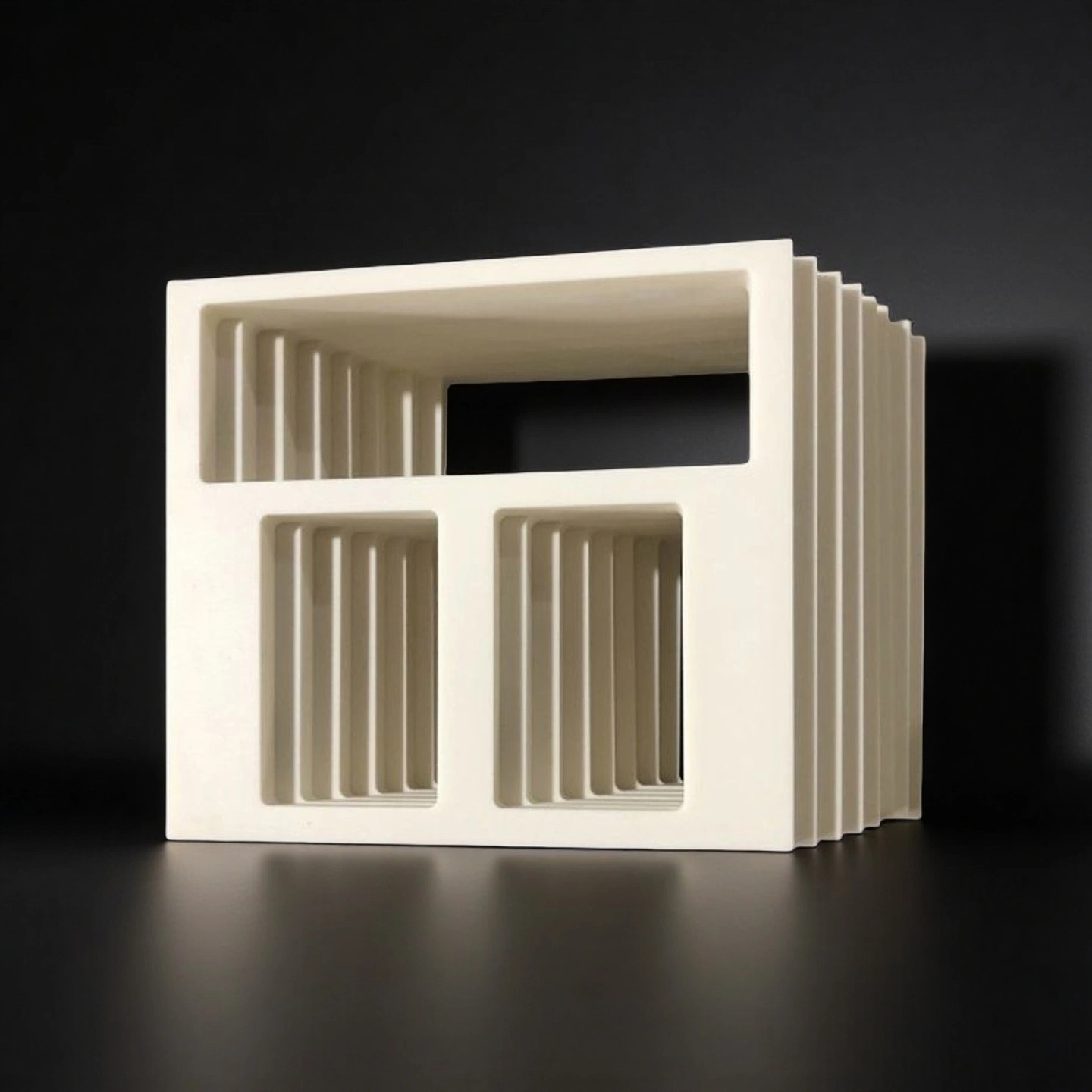

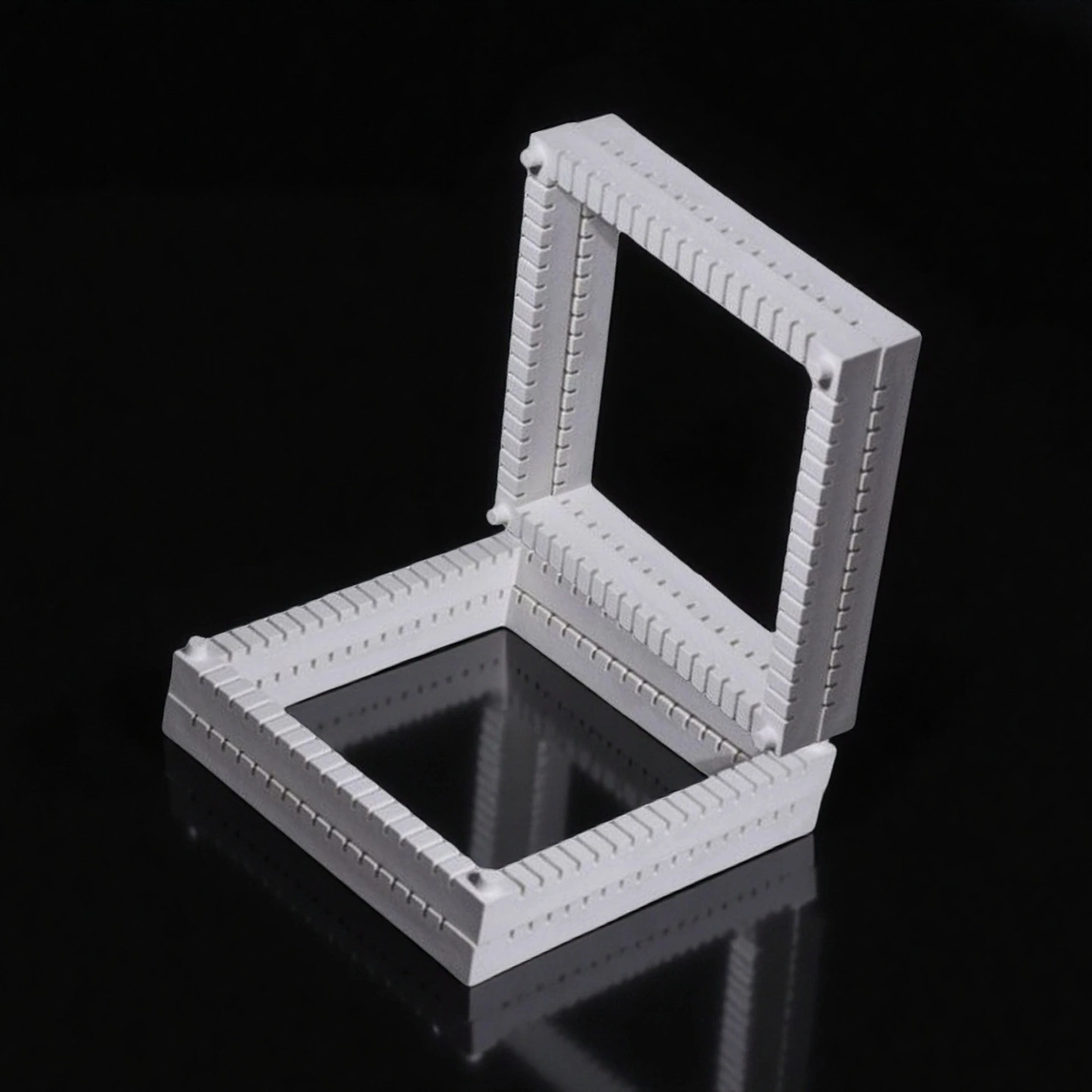

Alumina ceramic frames are square or rectangular structural borders made from approximately 95% Al₂O₃, used as insulating base parts and housings in industrial devices. They combine high mechanical strength, hardness, thermal stability and electrical insulation, so they can support and protect electronic components, sensors and actuators in harsh environments such as high temperature, high humidity or corrosive atmospheres.

Alumina Ceramic Frame Benefits

-

High strength and hardness for structural support

The alumina ceramic frame carries mechanical loads and resists surface wear, so it can act as a stable structural border or base in long-term industrial operation without deformation or rapid abrasion. -

High-temperature and oxidation resistance

95% alumina maintains its properties at elevated temperatures and in oxidizing atmospheres, which helps the alumina ceramic frame keep its shape and function in furnaces, hot zones and high-temperature insulating devices. -

Reliable electrical insulation

The alumina ceramic frame provides a rigid insulating barrier between conductive parts and metal housings, helping protect integrated circuits, discrete components and sensor elements from leakage and short circuits. -

Dimensional precision for accurate positioning

The frame’s inner window size, thickness and flatness can be tightly controlled, so critical electronic parts, substrates or sensor chips sit in defined positions, supporting high-precision assemblies. -

Environmentally inert ceramic material

The alumina ceramic frame is based on an inorganic ceramic body without volatile organic compounds, making it a stable, inert choice for devices where outgassing or contamination must be minimized.

Alumina Ceramic Frame Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

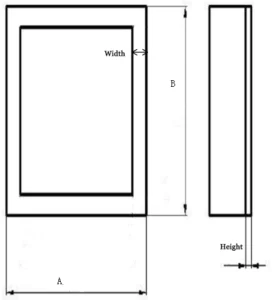

Alumina Ceramic Frame Specifications

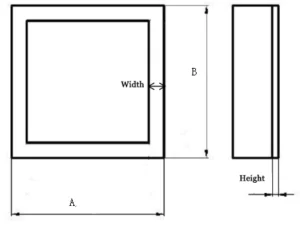

Type 1: Rectangle Alumina Ceramic Frame

| Rectangle Alumina Ceramic Frame | |||||

| Item No. | A(mm) | B(mm) | Width (mm) | Height (mm) | Purity (%) |

| AT-CF-F001 | 20 | 30 | 3 | 4 | 96-99 |

| AT-CF-F002 | 45 | 62 | 5 | 5 | 96-99 |

| AT-CF-F003 | 70 | 80 | 4 | 6 | 96-99 |

| AT-CF-F004 | 106 | 120 | 5 | 12 | 96-99 |

| AT-CF-F005 | 160 | 100 | 10 | 8 | 96-99 |

| AT-CF-F006 | 200 | 180 | 20 | 35 | 96-99 |

Type 2: Square Alumina Ceramic Frame

| Square Alumina Ceramic Frame | ||||

| Item No. | A = B (mm) | Width (mm) | Height (mm) | Purity (%) |

| AT-CF-Z001 | 20 | 5 | 5 | 96-99 |

| AT-CF-Z002 | 25 | 4 | 3 | 96-99 |

| AT-CF-Z003 | 30 | 3.5 | 8 | 96-99 |

| AT-CF-Z004 | 45 | 4.8 | 7.5 | 96-99 |

| AT-CF-Z005 | 60 | 12 | 16 | 96-99 |

| AT-CF-Z006 | 75 | 20 | 20 | 96-99 |

| AT-CF-Z007 | 86 | 15 | 15 | 96-99 |

| AT-CF-Z008 | 120 | 45 | 16 | 96-99 |

| AT-CF-Z009 | 130 | 30 | 18 | 96-99 |

Alumina Ceramic Frames Packaging

- Each alumina ceramic frame is separated with soft paper or foam sheets to avoid edge-to-edge contact and chipping during transport.