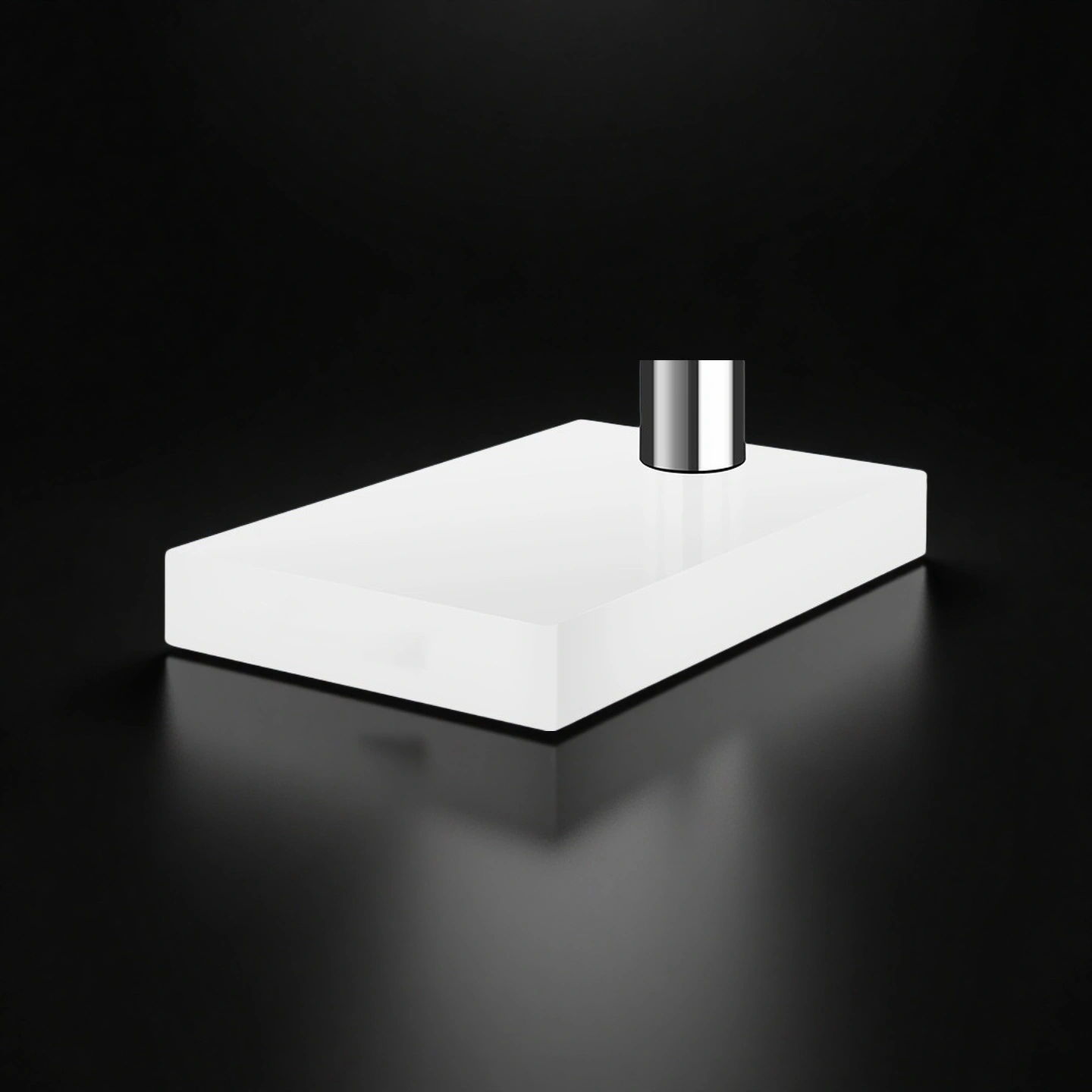

An alumina ceramic measuring platform is a high-flatness base plate made from aluminum oxide (Al₂O₃) used as a stable reference surface for CMMs, inspection fixtures, and precision measurement systems. It provides low thermal expansion, electrical insulation, and wear resistance to support accurate and repeatable measurements.

Alumina Ceramic Measuring Platform Benefits

-

Stable dimensional accuracy

The alumina ceramic measuring platform combines low thermal expansion with controlled flatness grades, helping maintain measurement accuracy when ambient temperature changes during production shifts. -

High hardness and wear resistance

99%+ alumina offers high hardness and abrasion resistance, so the platform surface resists scratches and local wear from repeated part loading, gauges, and fixtures. -

Electrically insulating and non-magnetic

The ceramic measuring platform is electrically insulating and non-magnetic, which supports stable readings for electronic probes, linear scales, and sensitive sensors mounted around the measuring area. -

Customizable interface features

Counterbored holes, threaded inserts, dowel pin positions, vacuum grooves, and part-location pockets can be integrated into the alumina ceramic measuring platform to match each customer’s fixture design. -

Corrosion-resistant for workshop and lab environments

Alumina ceramic resists coolants, lubricants, and many cleaning agents, which helps preserve surface quality when the platform is used close to machining or wet inspection processes.

Alumina Measuring Platform Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Ceramic Measuring Platform Specifications

| Alumina Ceramic Measuring Platform | ||||||

| Item No. | Length(mm) | Width (mm) | Thickness(mm) | Accuracy(mm) | Purity(%) | Shape |

| AT-YHL-CL001 | 60 | / | 15 | 0.0004 | 99 | Round |

| AT-YHL-CL002 | 80 | / | 15 | 0.0004 | 99 | |

| AT-YHL-CL003 | 100 | / | 20 | 0.0004 | 99 | |

| AT-YHL-CL004 | 65 | 75 | 15 | 0.0004 | 99 | Rectangle |

| AT-YHL-CL005 | 80 | 80 | 15 | 0.0004 | 99 | Square |

| AT-YHL-CL006 | 100 | 100 | 15 | 0.0004 | 99 | |

| AT-YHL-CL007 | 110 | 110 | 20 | 0.0004 | 99 | |

| AT-YHL-CL008 | 111 | 111 | 15 | 0.0004 | 99 | |

| AT-YHL-CL009 | 120 | 180 | 20 | 0.0004 | 99 | Rectangle |

| AT-YHL-CL010 | 150 | 100 | 20 | 0.0004 | 99 | |

| AT-YHL-CL011 | 150 | 100 | 50 | 0.0004 | 99 | |

| AT-YHL-CL012 | 150 | 150 | 20 | 0.0004 | 99 | Square |

| AT-YHL-CL013 | 200 | 150 | 50 | 0.0004 | 99 | Rectangle |

| AT-YHL-CL014 | 300 | 200 | 50 | 0.0004 | 99 | |

| AT-YHL-CL015 | 400 | 300 | 50 | 0.0004 | 99 | |

Aluminium Oxide Measuring Platform Packaging

- Each alumina ceramic measuring platform is wrapped in soft protective film to prevent scratching of the working surface.