Alumina Fiber Blanket is a flexible, needle-punched alumina–silicate ceramic fiber insulation material designed for continuous high-temperature applications. It is manufactured by converting alumina-rich ceramic fibers into layered mats and mechanically interlocking them through a needle-punching process, creating a resilient blanket with low thermal conductivity and low heat storage.

Alumina Fiber Blanket Benefits

-

Stable High-Temperature Performance

Alumina fiber blanket is classified for 1260–1430°C with controlled linear shrinkage (often ≤3% at rated temperature for 128 kg/m³), which helps maintain lining thickness and mechanical integrity during long-term operation. -

Low Thermal Conductivity and Low Heat Storage

For a 128 kg/m³ alumina fiber blanket, thermal conductivity at 800°C typically ranges around 0.15–0.18 W/(m·K), and the low heat capacity of the fiber structure supports fast heat-up and cool-down, reducing fuel consumption and cycle time compared with brick linings. -

Lightweight and Flexible for Complex Geometries

The low-density and flexible mat form allow the blanket to conform to furnace curves, doors, expansion joints, and non-standard geometries, which simplifies installation and reduces steel structure loads compared with conventional refractory bricks or castables. -

Needle-Punched Structure with Handling Strength

Double-sided needle punching interlocks the fibers through the thickness and provides tensile strength suitable for hanging systems, layered linings, and removable insulation pads without excessive fiber pull-out during installation. -

Compatible with Multilayer Refractory Systems

Alumina fiber blanket can be used as a hot-face or backup insulation behind bricks, modules, or boards to form multi-layer systems with optimized heat loss control and lower shell temperatures, supporting modern energy-efficiency standards in industrial plants.

Alumina Fiber Blanket Properties

| Chemical Composition | |||||

| Item | 1000°C Fiber Blanket | 1260 °C Fiber Blanket | 1425°C Fiber Blanket | 1500°C Fiber Blanket | 1600°C Fiber Blanket |

| AI2O3 | 42-44% | 45-47% | 34-36% | 41-43% | 72% |

| SiO2 | 56-58% | 53-55% | 49-51% | 54-56% | 28% |

| ZrO2 | - | - | 14-17% | - | - |

| Cr2O3 | - | - | - | 2-3% | - |

| Physical Properties | |||||

| Item | 1000 | 1260 | 1425 | 1500 | 1600 |

| Classification Temperature (°C) | 1000 | 1260 | 1425 | 1500 | 1600 |

| Melting Point (°C) | 1700 | 1760 | 1700 | 1760 | - |

| Color | White | White | White | Light Green | White |

| Average Fiber Diameter (mm) | 2.6 | 2.6 | 2.8 | 2.65 | 3.1 |

| Fiber Length (mm) | ~200 | ~250 | ~250 | ~150 | ~100 |

| Bulk Density(kg/m3) | 2600 | 2600 | 2800 | 2650 | 3100 |

| Thermal Conductivity (W/m·K) 400℃ | 0.15 | 0.13 | - | - | - |

| Thermal Conductivity (W/m·K) 600℃ | 0.22 | 0.19 | 0.13 | 0.13 | 0.06 |

| Thermal Conductivity (W/m·K) 800℃ | 0.31 | 0.25 | 0.2 | 0.19 | 0.1 |

| Thermal Conductivity (W/m·K) 1000℃ | - | - | 0.29 | 0.26 | 0.14 |

Alumina Fiber Blanket Specifications

| Alumina Fiber Blanket | |||||

| Item no. | Working Temp.(℃) | Density(kg/m3) | Length(mm) | Width(mm) | Thickness(mm) |

| AT-GSL-T1001 | 1260 | 96 128 160 | 7200 | 610 | 6 |

| AT-GSL-T1002 | 96 128 160 | 15000 | 610 | 10 | |

| AT-GSL-T1003 | 96 128 160 | 7200 | 610 | 20 | |

| AT-GSL-T1004 | 96 128 160 | 7200 | 610 | 25 | |

| AT-GSL-T1005 | 96 128 160 | 5000 | 610 | 30 | |

| AT-GSL-T1006 | 96 128 160 | 3600 | 610 | 50 | |

| AT-GSL-T1007 | 1400 | 96 128 160 | 7200 | 610 | 6 |

| AT-GSL-T1008 | 96 128 160 | 15000 | 610 | 10 | |

| AT-GSL-T1009 | 96 128 160 | 7200 | 610 | 20 | |

| AT-GSL-T1010 | 96 128 160 | 7200 | 610 | 25 | |

| AT-GSL-T1011 | 96 128 160 | 5000 | 610 | 30 | |

| AT-GSL-T1012 | 96 128 160 | 3600 | 610 | 50 | |

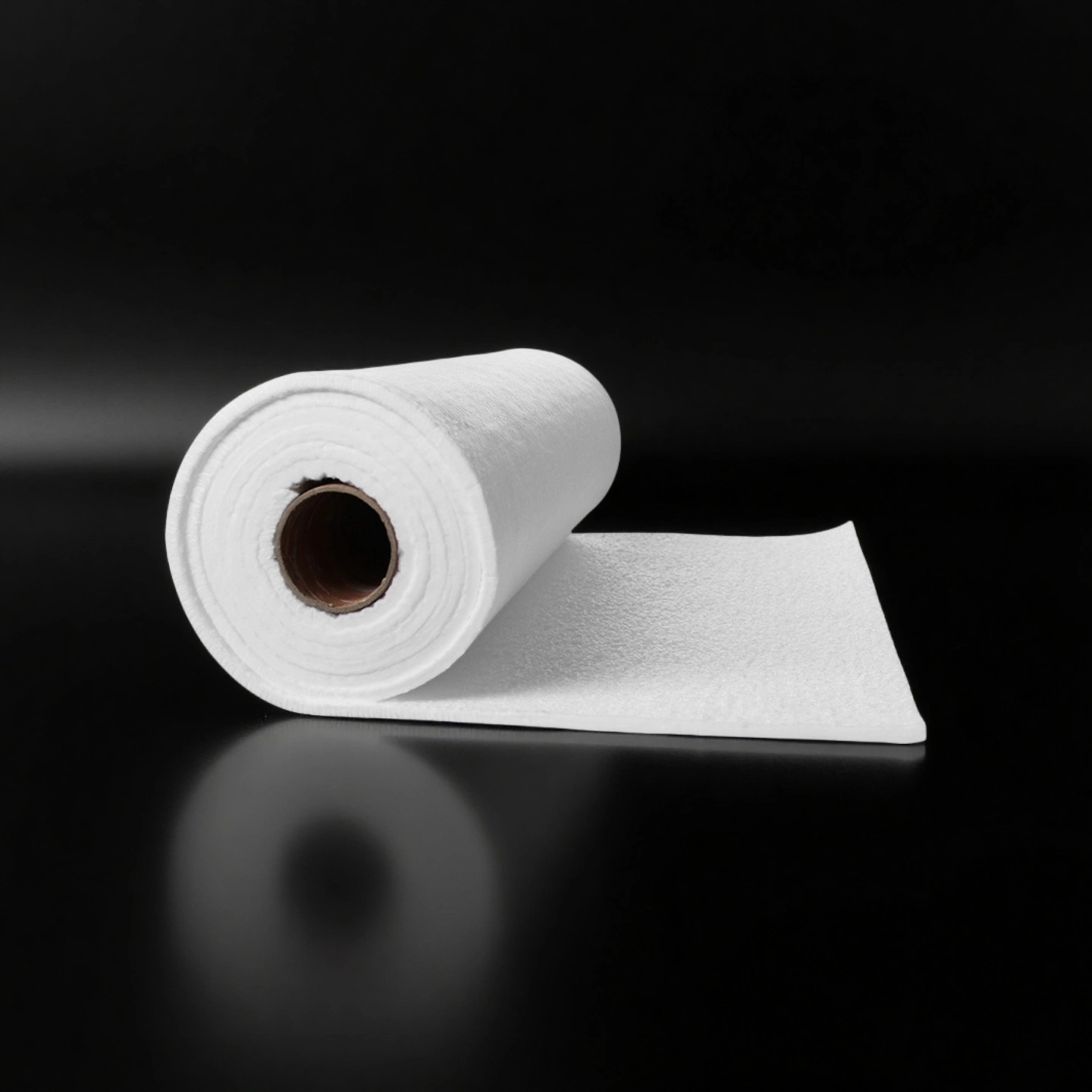

Alumina Ceramic Fiber Blanket Packaging

- Each alumina fiber blanket roll is wrapped in plastic film to limit moisture pickup and fiber loss during handling.