An alumina grinding jar is a high-density Al₂O₃ ceramic container used in planetary, roller and laboratory ball mills for grinding hard, abrasive or contamination-sensitive powders. It provides a chemically inert, wear-resistant milling chamber that minimizes metallic impurities while delivering stable performance in both dry and wet grinding applications.

Alumina Grinding Jar Benefits

-

Low contamination grinding chamber

The alumina grinding jar provides an Al₂O₃ interface that avoids iron or nickel pickup from steel jars, suitable for high-purity powders and battery materials. -

High wear resistance and long jar life

High-density alumina with Vickers hardness around 18–20 GPa resists abrasion under repeated high-speed impacts from grinding media. -

Stable performance at elevated temperatures

Alumina ceramics maintain strength and chemical stability above 1,500 °C, so the jar remains dimensionally stable under frictional heating during intensive milling. -

Acid and alkali-resistant inner surface

The jar can be used with many aqueous slurries and common process chemicals without significant corrosion or leaching. -

Compatible with common grinding media configurations

The jar geometry supports standard alumina or zirconia ball size combinations (for example 3–20 mm) used in planetary mills for fine and ultra-fine grinding.

Alumina Ceramic Grinding Jar Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Grinding Jar Specifications

Recommended quantity of grinding balls (for reference)

| Alumina Grinding Mill Capacity | 100ML | 250ML | 500ML | 1000ML |

| Grinding ball Weight | 66g | 165g | 330g | 660g |

| Φ5mm grinding ball(0.25g/pcs) | 106pcs | 300pcs | ||

| Φ10mm grinding ball(1.99g/pcs) | 20pcs | 76pcs | 50pcs | 100pcs |

| Φ15mm grinding ball(6.72g/pcs) | 4pcs | 30pcs | 59pcs | |

| Φ20mm grinding ball(15.92g/pcs) | 3pcs | 5pcs |

Type 1: Vertical (Cylindrical) Alumina Grinding Jar

| Cylindrical Alumina Grinding Jar | |||||||

| Item No. | Capacity | Outer Diameter(mm) | Inner Diameter(mm) | Height Without Lid (mm) | Height of Lid(mm) | Total Height (mm) | Thickness ((mm) |

| AT-J-01 | 50ml | 55 | 38 | 60 | 8 | 67 | 8 |

| AT-J-02 | 100ml | 65 | 50 | 66 | 8 | 45 | 8 |

| AT-J-03 | 250ml | 92 | 74 | 78 | 9 | 88 | 8 |

| AT-J-04 | 500ml | 100 | 84 | 108 | 9 | 118 | 9 |

| AT-J-05 | 1L | 128 | 108 | 117 | 10 | 150 | 10 |

| AT-J-06 | 1.5L | 132 | 112 | 158 | 10 | 175 | 10 |

| AT-J-07 | 2.0L | 158 | 138 | 151 | 12 | 162 | 10 |

| AT-J-08 | 2.5L | 170 | 150 | 160 | 12 | 170 | 10 |

| AT-J-09 | 3.0L | 158 | 138 | 185 | 12 | 220 | 10 |

Type 2: Horizontal Alumina Grinding Jar

| Horizontal Alumina Grinding Jar | |||

| Item NO. | Capacity | Outer Diameter (mm) | Inner Diameter(mm) |

| AT-J-10 | 50ml | 64 | 59 |

| AT-J-11 | 100ml | 69 | 66 |

| AT-J-12 | 250ml | 90 | 78 |

| AT-J-13 | 500ml | 106 | 99 |

| AT-J-14 | 1L | 133 | 126 |

| AT-J-15 | 1.5L | 172mm | 152mm |

| AT-J-16 | 2.0L | 210mm | 168mm |

| AT-J-17 | 3.0L | 265mm | 200mm |

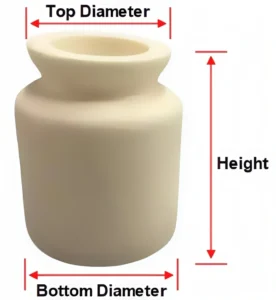

Type 3: Alumina Ball Mill Jar for Petanque Grinder

| Alumina Ball Mill Jar for Petanque Grinder | ||||

| Item No. | Top Diameter (mm) | Bottom Diameter (mm) | Height(mm) | Height+Lid (mm) |

| AT-AM-01 | 124 | 153 | 140 | 190 |

| AT-AM-02 | 148 | 180 | 175 | 235 |

Type 4: Alumina Grinding Mill with Lid

| Alumina Grinding Mill with Lid | |||

| Item No. | Capacity (L) | Outer Diameter*Height (mm) | Weight (KG) |

| AT-AM-03 | 30-40 | 400*600 | 20-22 |

| AT-AM-04 | 18-18.5 | 300*400 | 18 |

| AT-AM-05 | 15-16 | 300*330 | 14-15 |

| AT-AM-06 | 10-14 | 270*320 | 11 |

| AT-AM-07 | 5-6.5 | 220*260 | 9 |

| AT-AM-08 | 3-5 | 180*250 | 6 |

| AT-AM-09 | 1.5 | 150*180 | 5.4 |

| AT-AM-10 | 1 | 130*170 | 5 |

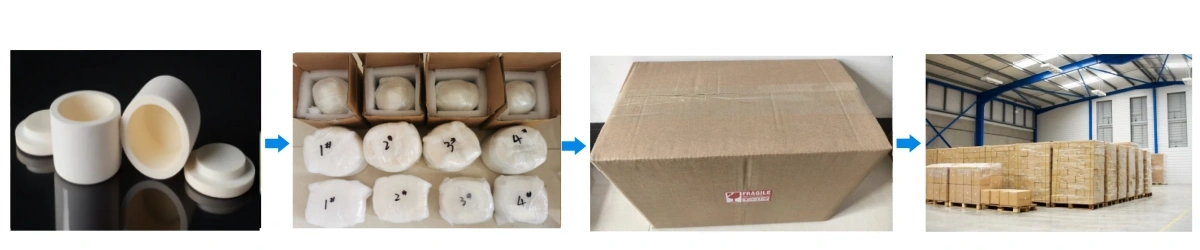

Alumina Grinding Jar Packaging

- Each alumina grinding jar and lid is wrapped with cushioning material to protect the rim and sealing surfaces.