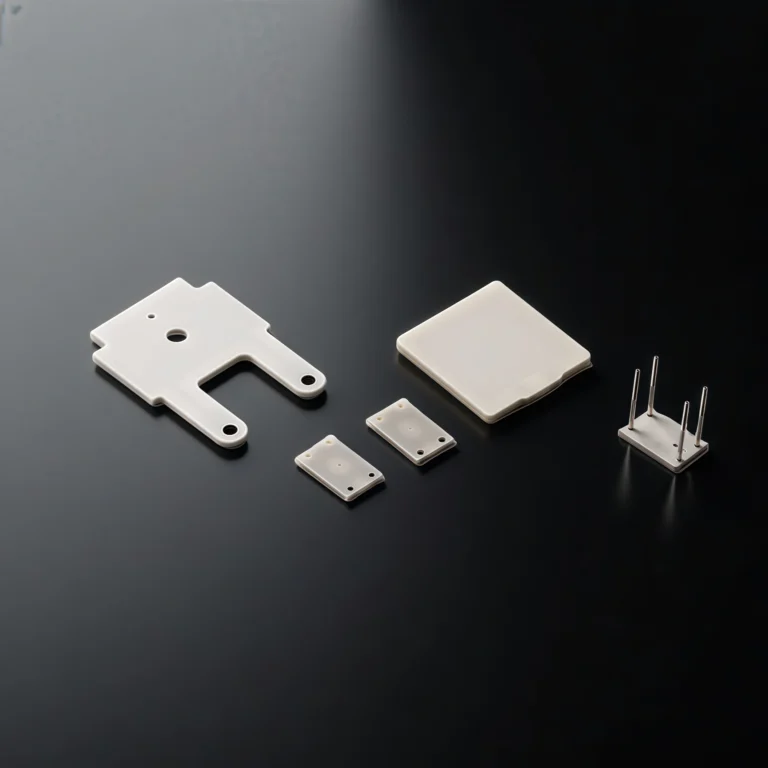

Alumina heaters are metal-ceramic heating elements made from high-purity Al₂O₃. They use printed tungsten or molybdenum heating circuits co-sintered with the ceramic at about 1,600 °C, forming a compact, insulated body. These alumina ceramic heaters feature fast heat-up (to 600–700 °C within 20 s), high power density (≥ 45 W/cm²), and strong dielectric strength (≈ 4.5 kV/1 s).

Alumina Heaters Benefits

-

High power density in small footprints — enables shorter dwell or smaller heater count.

-

Uniform surface heating — reduces hot spots and improves part-to-part consistency.

-

Electrically insulated surface — supports safe integration near grounded tooling.

-

Stable R–T behaviour — simplifies PID tuning and maintains set-point accuracy.

-

Thermal robustness of Al₂O₃ — tolerates cyclic operation and moderate thermal shock.

Alumina Heaters Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Ceramic Heater Specifications

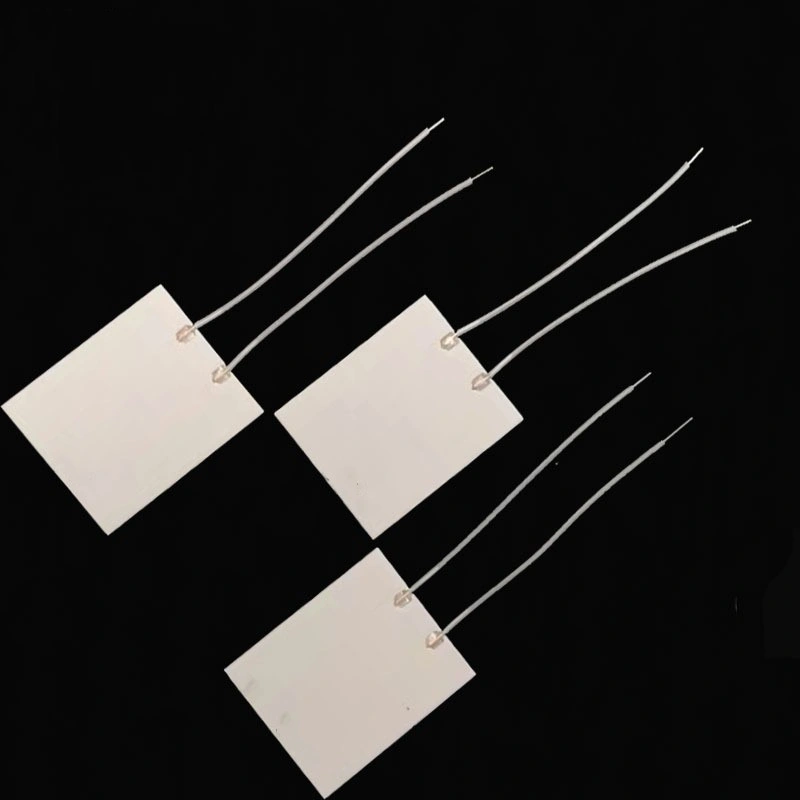

Type 1: Square Alumina Heaters

| Square Alumina Heaters | ||||

| Item No. | Length(mm) | Width(mm) | Thickness(mm) | Resistance |

| AT-YHL-JRQ001 | 10 | 10 | 1.3 | 4.8V |

| AT-YHL-JRQ002 | 10 | 10 | 1.3 | 12V |

| AT-YHL-JRQ003 | 12 | 12 | 1.3 | 12V |

| AT-YHL-JRQ004 | 12 | 12 | 1.3 | 24V |

| AT-YHL-JRQ005 | 15 | 15 | 1.3 | 72V |

| AT-YHL-JRQ006 | 18 | 18 | 1.3 | 4.8V |

| AT-YHL-JRQ007 | 22 | 22 | 1.3 | 12V |

| AT-YHL-JRQ008 | 24 | 24 | 1.3 | 48V |

| AT-YHL-JRQ009 | 25 | 25 | 1.3 | 60V |

| AT-YHL-JRQ010 | 30 | 30 | 1.3 | 24V |

| AT-YHL-JRQ011 | 35 | 35 | 1.3 | 48V |

| AT-YHL-JRQ012 | 40 | 40 | 1.3 | 220V |

| AT-YHL-JRQ013 | 15 | 15 | 1.3 | 24V |

Type 2: Round Alumina Heaters

| Round Alumina Heaters | |||

| Item No. | Diameter(mm) | Thickness(mm) | Resistance |

| AT-YHL-JRQ014 | 7 | 0.6 | 110V |

| AT-YHL-JRQ015 | 9 | 0.8 | 110V |

| AT-YHL-JRQ016 | 9 | 1.3 | 24V |

| AT-YHL-JRQ017 | 10 | 1.3 | 5V/12V |

| AT-YHL-JRQ018 | 11 | 0.8 | 3.7V |

| AT-YHL-JRQ019 | 11 | 1.3 | 5V |

| AT-YHL-JRQ020 | 13 | 0.8 | 5V |

| AT-YHL-JRQ021 | 14 | 1.3 | 20V |

| AT-YHL-JRQ022 | 16 | 1.3 | 5V/12V |

| AT-YHL-JRQ023 | 19 | 1.3 | 5V/12V |

| AT-YHL-JRQ024 | 20 | 1.3 | 12V/72V |

| AT-YHL-JRQ025 | 24 | 1.3 | 5V/12V |

| AT-YHL-JRQ026 | 26 | 1.3 | 12V/24V |

| AT-YHL-JRQ027 | 28 | 1.3 | 24V |

| AT-YHL-JRQ028 | 30 | 1.3 | 5V |

| AT-YHL-JRQ029 | 30 | 1.3 | 12V/24V |

| AT-YHL-JRQ030 | 30 | 2 | 24V |

| AT-YHL-JRQ031 | 38 | 38.5 | 24V |

| AT-YHL-JRQ032 | 39 | 39.7 | 24V |

| AT-YHL-JRQ033 | 40 | 1.3 | 12V/24V |

| AT-YHL-JRQ034 | 48 | 2 | 12V/110V |

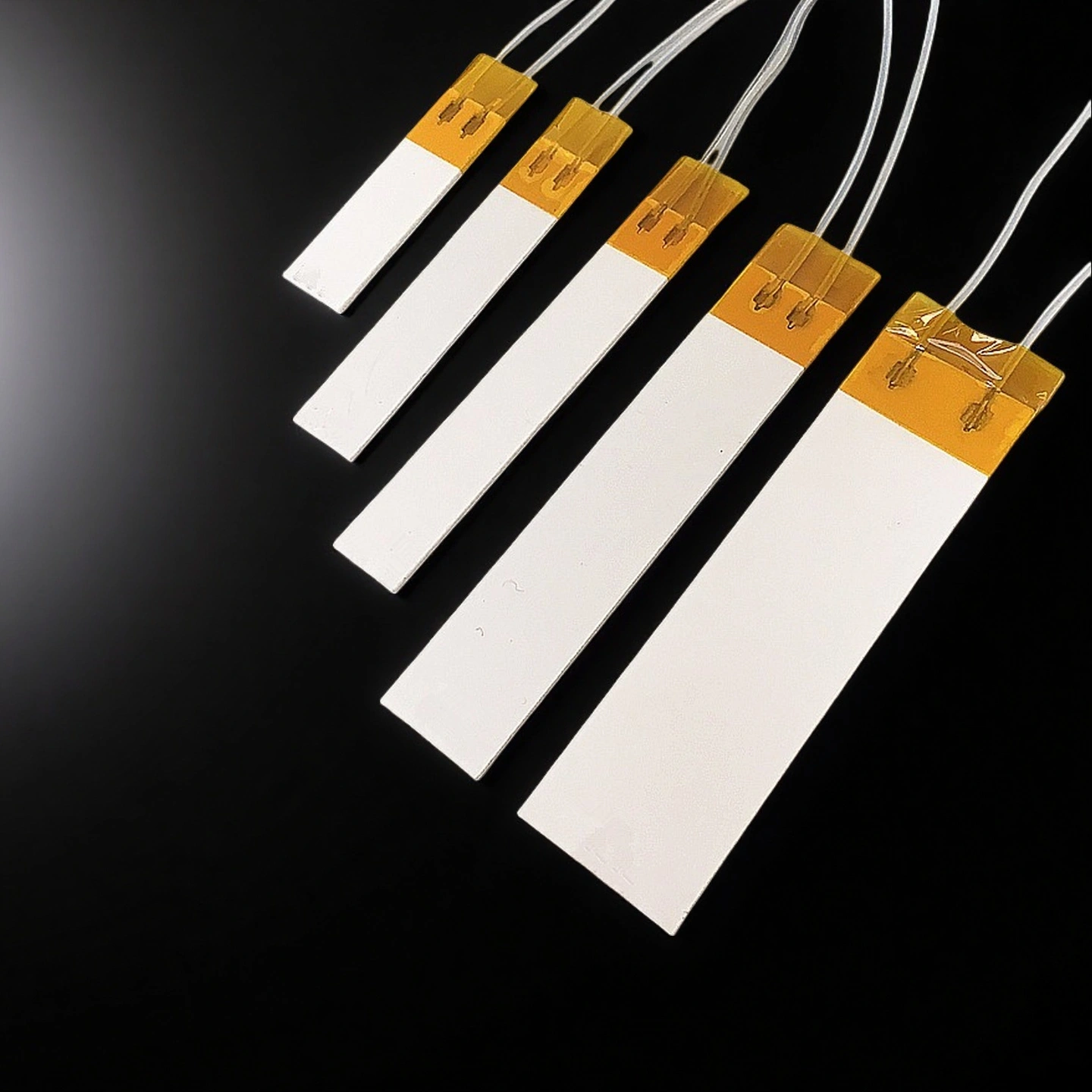

Type 3: Rectangle Alumina Heaters

| Rectangle Alumina Heaters | ||||

| Item No. | Length(mm) | Width(mm) | Thickness(mm) | Resistance |

| AT-YHL-JRQ035 | 10 | 7 | 1.3 | 5V/12V |

| AT-YHL-JRQ036 | 15 | 7 | 1.3 | 24V |

| AT-YHL-JRQ037 | 15 | 10 | 1.3 | 5V |

| AT-YHL-JRQ038 | 25 | 7 | 1.3 | 5V |

| AT-YHL-JRQ039 | 20 | 15 | 1.3 | 12V/24V |

| AT-YHL-JRQ040 | 30 | 25 | 1.3 | 12V/24V |

| AT-YHL-JRQ041 | 35 | 20 | 1.3 | 5V/12V |

| AT-YHL-JRQ042 | 35 | 15 | 1.3 | 48V |

| AT-YHL-JRQ043 | 35 | 7 | 1.3 | 5V |

| AT-YHL-JRQ044 | 40 | 30 | 1.3 | 5V |

| AT-YHL-JRQ045 | 55 | 10 | 1.3 | 3.7V/5V/12V |

| AT-YHL-JRQ046 | 55 | 20 | 1.3 | 110V |

| AT-YHL-JRQ047 | 60 | 20 | 1.3 | 5V/12V |

| AT-YHL-JRQ048 | 70 | 30 | 1.3 | 24V/110V/220V |

| AT-YHL-JRQ049 | 70 | 7 | 1.3 | 12V/24V/110V/220V |

| AT-YHL-JRQ050 | 80 | 15 | 1.3 | 220V |

| AT-YHL-JRQ051 | 90 | 10 | 1.3 | 110V/220V |

| AT-YHL-JRQ052 | 100 | 10 | 1.3 | 220V |

Type 4: Cylindrical Alumina Heaters

| Cylindrical Alumina Heaters | |||

| Item No. | Diameter(mm) | Length (mm) | Resistance |

| AT-YHL-JRQ053 | 2 | 2.9 | 12V |

| AT-YHL-JRQ054 | 2 | 2.9 | 24V |

| AT-YHL-JRQ055 | 3 | 32 | 12V |

| AT-YHL-JRQ056 | 3 | 57 | 12V |

| AT-YHL-JRQ057 | 3 | 57 | 24V |

| AT-YHL-JRQ058 | 3 | 3.8 | 12V |

| AT-YHL-JRQ059 | 3 | 3.8 | 22V |

| AT-YHL-JRQ060 | 3 | 3.8 | 220V |

| AT-YHL-JRQ061 | 4 | 4 | 22V |

| AT-YHL-JRQ062 | 4 | 4.5 | 110V |

| AT-YHL-JRQ063 | 4 | 4.5 | 220V |

| AT-YHL-JRQ064 | 4 | 70 | 220V |

| AT-YHL-JRQ065 | 8 | 70 | 110V |

| AT-YHL-JRQ066 | 8 | 80 | 110V |

| AT-YHL-JRQ067 | 15 | 84 | 110V |

| AT-YHL-JRQ068 | 50 | 3.8 | 24V |

| AT-YHL-JRQ069 | 60 | 3.8 | 110V |

| AT-YHL-JRQ070 | 60 | 3.8 | 220V |

| AT-YHL-JRQ071 | 70 | 5.5 | 220V |

| AT-YHL-JRQ072 | 75 | 5 | 220V |

Type 5: Tubular Alumina Heaters

| Tubular Alumina Heaters | |||

| Item NO. | Inner Diameter(mm) | Outer Diameter(mm) | Length(mm) |

| AT-YHL-JRQ073 | 9 | 13 | 23 |

| AT-YHL-JRQ074 | 10 | 11.4 | 20 |

| AT-YHL-JRQ075 | 9 | 10.2 | 11.5 |

| AT-YHL-JRQ076 | 11 | 12.4 | 14.44 |

| AT-YHL-JRQ077 | 10 | 11.4 | 20 |

| AT-YHL-JRQ078 | 11 | 12.4 | 14.4 |

| AT-YHL-JRQ079 | 9 | 13 | 23 |

| AT-YHL-JRQ080 | 14 | 16 | 15 |

| AT-YHL-JRQ081 | 18 | 21.4 | 50 |

| AT-YHL-JRQ082 | 18 | 21.5 | 55 |

Alumina Ceramic Heater Packaging

- Each unit is plastic-wrapped and packed in anti-vibration export cartons. Large diameters or fragile structures are enclosed in a padded wooden casing. Packaging is moisture-proof and shock-resistant.