Alumina Nozzle is a precision flow-control component made from high-density alumina (Al₂O₃) ceramic. It shapes and delivers liquids or gases into a defined spray or jet—maintaining orifice geometry and spray pattern under abrasive, corrosive, or high-temperature conditions where metal or polymer nozzles wear quickly.

Alumina Ceramic Nozzle Benefits

-

Spray geometry retention — orifice holds shape over long abrasive duty, keeping angle and droplet spectrum stable.

-

Anti-clog bore finish — low-porosity, smooth channel reduces particulate hang-up and pressure spikes.

-

Seat & thread fit — repeatable sealing to manifold/torch heads, lowering leak-induced variability.

-

Thermal stability in cycling — low expansion supports rapid heat/cool cycles without shift in flow.

-

Geometry flexibility — spiral, cone, and TIG cup forms to match fogging, jetting, or shielding needs.

Alumina Ceramic Nozzle Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina nozzle Size

Type 1: Spiral Alumina Nozzle

| Spiral Alumina Nozzle | |||||

| Item No. | Hole Diameter (mm) | Jet angle (°) | Operating Temperature(℃) | Pressure(bar) | medium |

| AT-SN-DN8 | 8 | 120 | 800 | 0.7 | liquid |

| AT-SN-DN10 | 10 | 120 | 800 | 0.7 | liquid |

| AT-SN-DN15 | 15 | 120 | 800 | 0.7 | liquid |

| AT-SN-DN20 | 20 | 120 | 800 | 0.7 | liquid |

| AT-SN-DN25 | 25 | 120 | 800 | 0.7 | liquid |

| AT-SN-DN32 | 32 | 120 | 800 | 0.7 | liquid |

| AT-SN-DN40 | 40 | 120 | 800 | 0.7 | liquid |

| AT-SN-DN50 | 50 | 120 | 800 | 0.7 | liquid |

Type 2: Vortex Alumina Nozzle

| Vortex Alumina Nozzle | |||||

| Item No. | Hole Diameter (mm) | Jet angle (°) | Operating Temperature(℃) | Pressure(bar) | medium |

| AT-SN-DN060 | 15 | 120 | 800 | 0.7 | liquid |

| AT-SN-DN070 | 20 | 120 | 800 | 0.7 | liquid |

| AT-SN-DN080 | 25 | 120 | 800 | 0.7 | liquid |

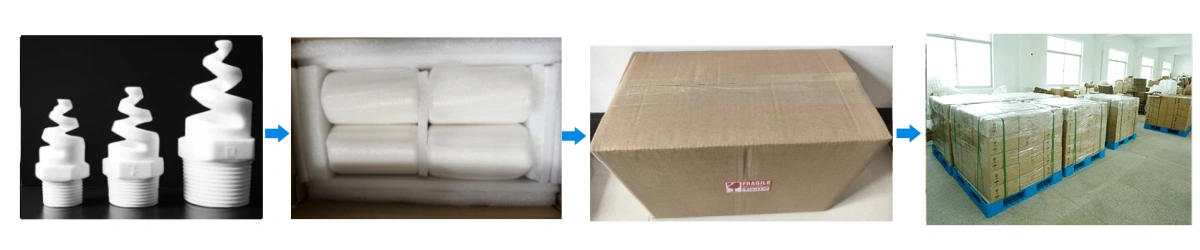

Alumina Nozzle Packaging

- Impact-safe inner trays with cell partitions; foam-lined small boxes