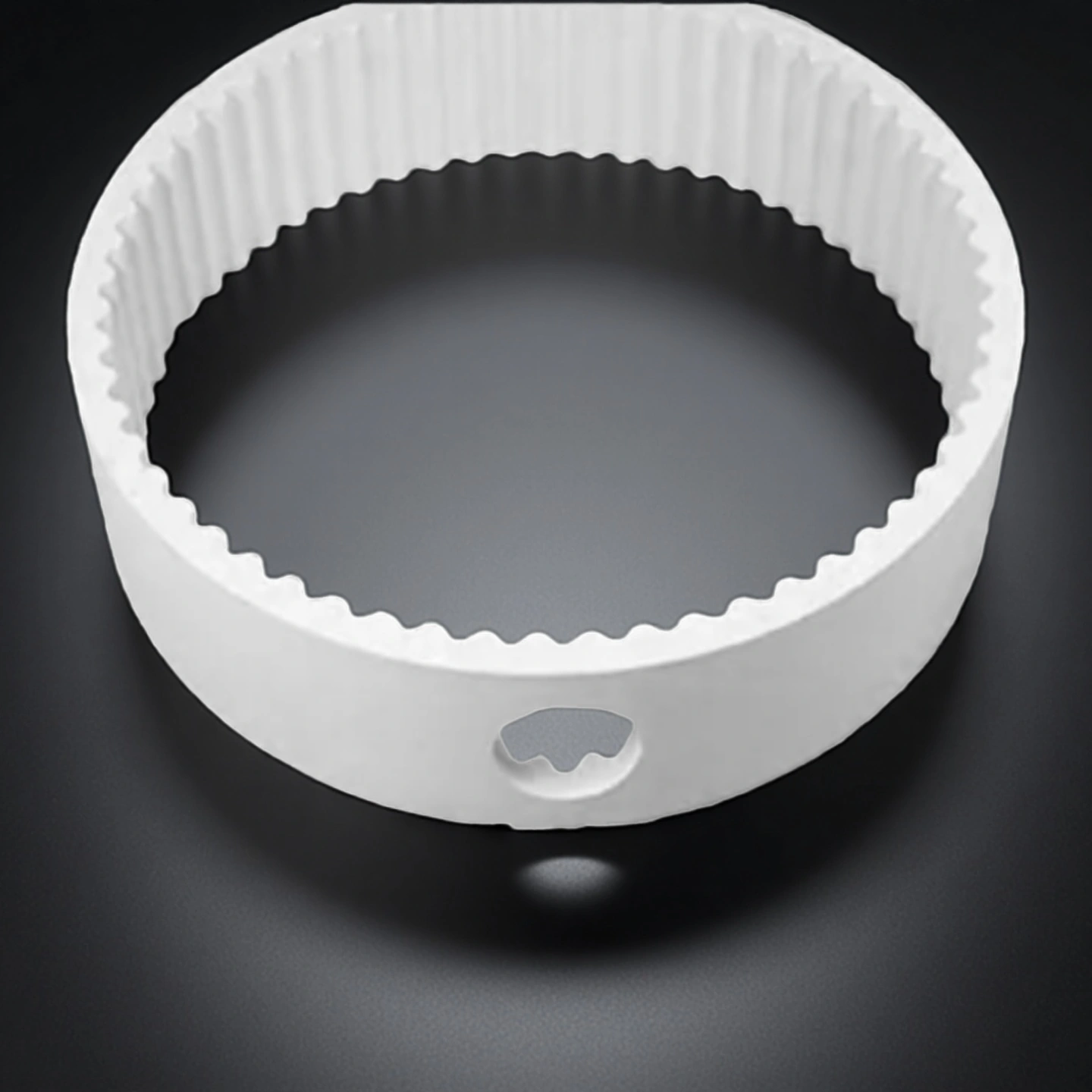

Alumina ring gears are precision-machined ceramic gear rings made from high-purity Al₂O₃, designed for transmission and indexing functions in pumps, flow meters, actuators and compact automation systems. The ceramic gear ring combines high hardness, dimensional stability and electrical insulation, making it suitable for high-duty cycles in corrosive and high-temperature environments.

Alumina Ring Gear Benefits

-

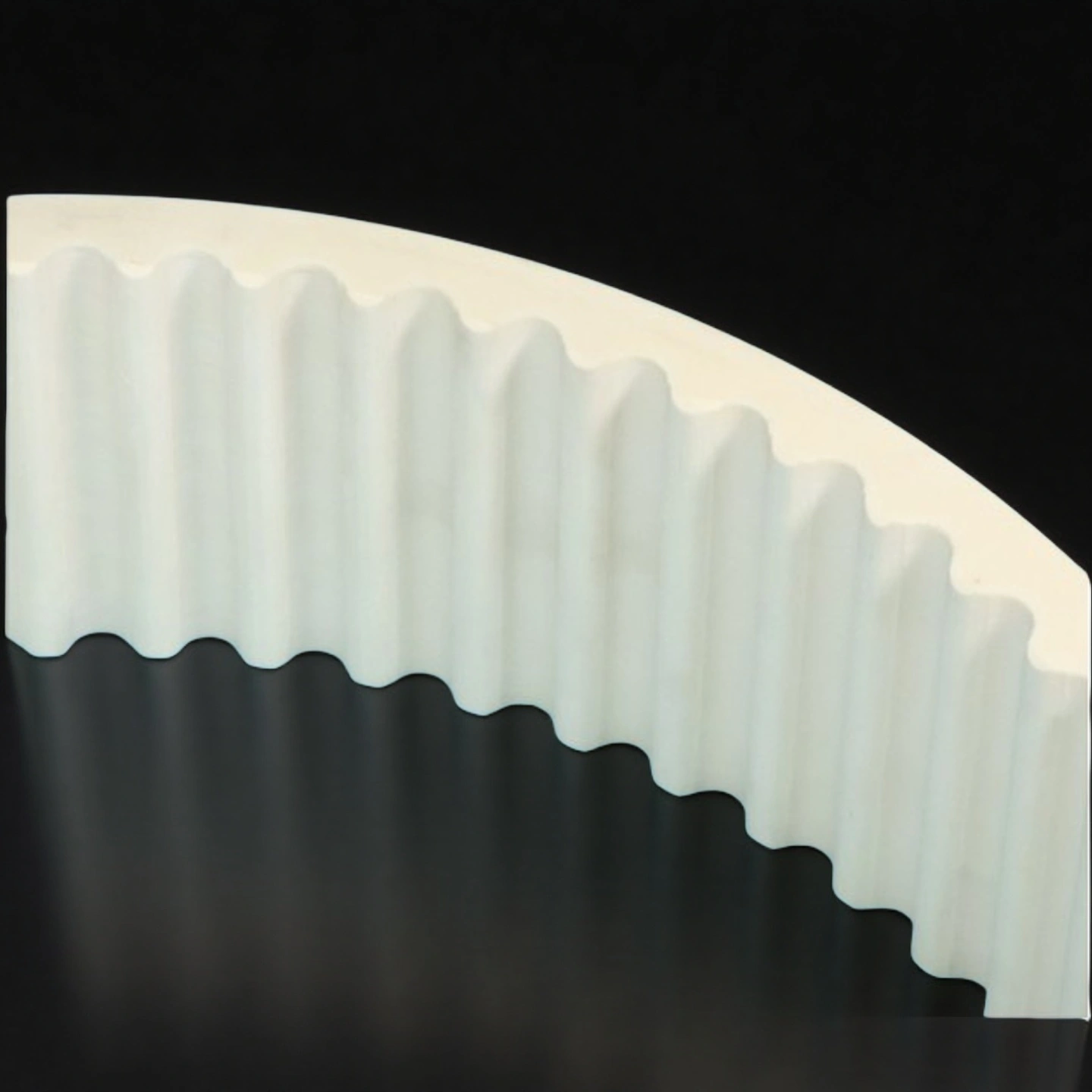

Stable tooth profile for precise metering

Tooth form and pitch are machined for repeatable engagement, helping maintain volumetric accuracy in gear pumps and dosing units over long operating hours. -

Extended wear life in abrasive and corrosive media

High hardness and chemical resistance of alumina reduce tooth wear when handling filled, viscous, or chemically aggressive fluids, lowering the frequency of gear replacement compared with metal gears. -

Electrical insulation within compact drives

The alumina ring gear provides insulation between rotating elements and adjacent metallic parts, which is valuable in motor-driven valves, actuators and instrumentation where stray currents or tracking must be avoided. -

Tight runout and concentricity for low noise and smooth rotation

Gear rings can be ground on functional surfaces to control radial runout and concentricity, which helps reduce vibration, noise and uneven loading in high-speed or low-flow applications. -

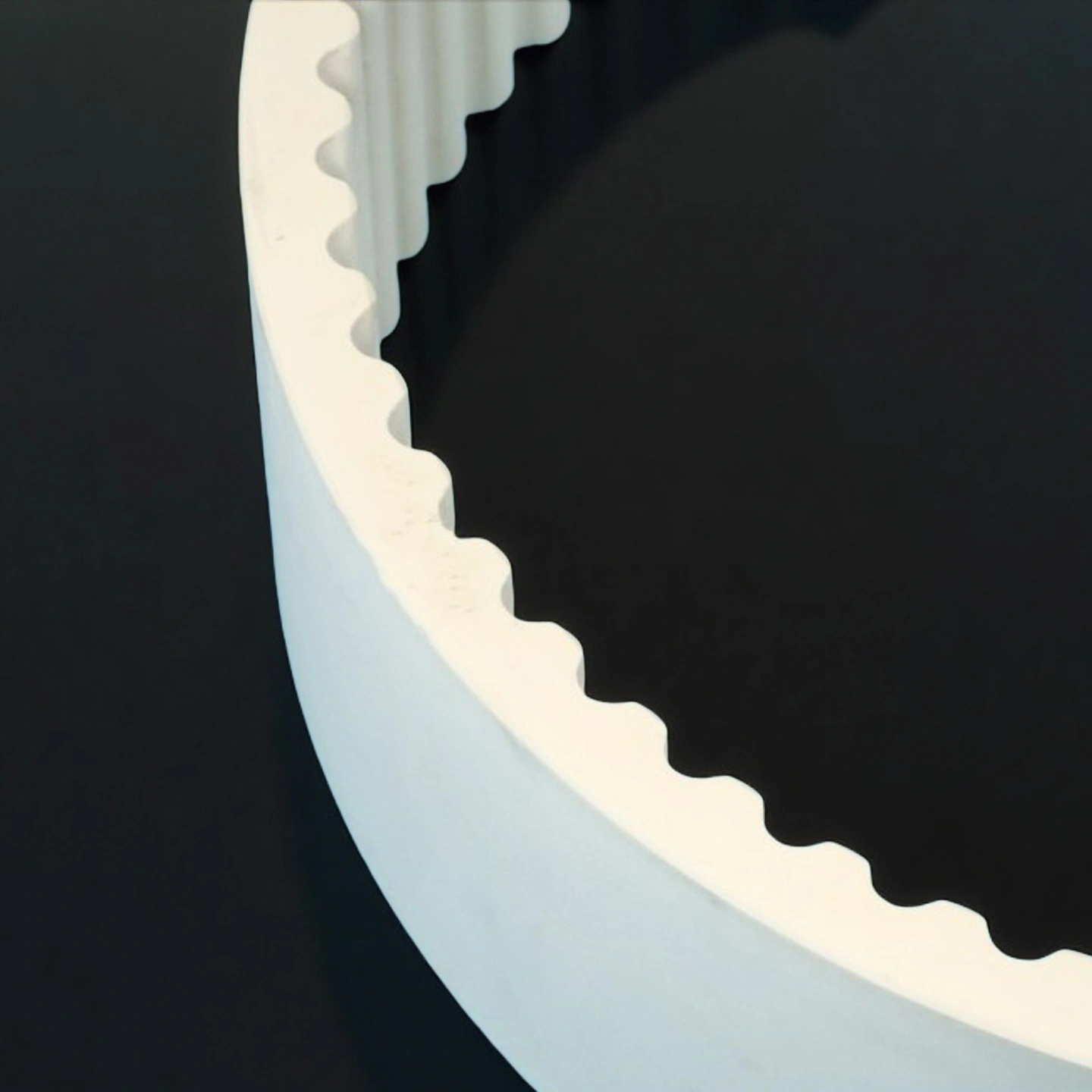

Configurable for small module and compact geometries

Alumina’s strength allows design of thin-walled, small-module ring gears that still maintain mechanical integrity, meeting the needs of miniature pumps, micropumps and compact automation units.

Alumina Ceramic Ring Gear Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Ring Gear Specifications

| Alumina Ring Gear | ||||||

| Item No. | Outer Diameter(mm) | Inner Diameter(mm) | Thickness(mm) | Height(mm) | Number of Gear | Purity(%) |

| AT-SM-C001 | 360 | 334 | 13 | 65 | 80 | 95-99 |

| AT-SM-C002 | 460 | 420 | 20 | 100 | 70 | 95-99 |

| AT-SM-C003 | 490 | 440 | 25 | 120 | 80 | 95-99 |

| AT-SM-C004 | 500 | 450 | 25 | 120 | 140 | 95-99 |

| AT-SM-C005 | 640 | 600 | 20 | 136 | 200 | 95-99 |

| AT-SM-C006 | 700 | 650 | 25 | 157 | 220 | 95-99 |

Alumina Ceramic Ring Gear Packaging

- Each alumina ring gear is individually protected with soft cushioning or blister packaging to avoid chipping of tooth edges during transport.