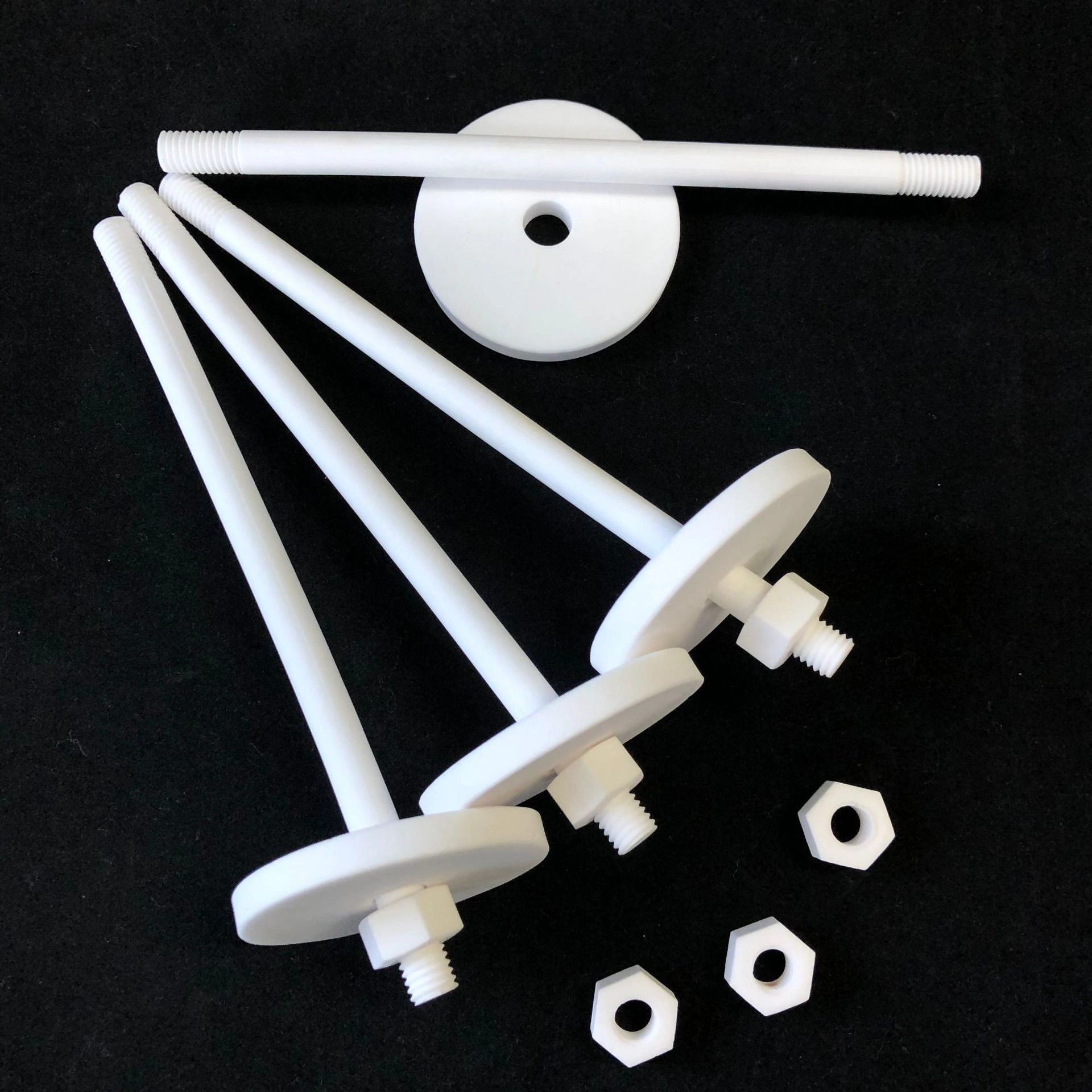

Alumina screws (alumina ceramic screws/bolts) are fastening components manufactured from aluminum oxide (Al₂O₃) technical ceramics. They are used when a joint must remain electrically insulating, non-magnetic, and dimensionally stable at elevated temperatures or near corrosive media where metallic fasteners oxidize, seize, or contaminate the assembly.

Alumina Screws Benefits

- High Purity Raw Material: Made from dense ≥99.7% fused alumina for structural integrity.

- Excellent Electric Insulation: Dielectric strength >18kV/mm prevents electrical leakage.

- Thermal Stability: Withstands temperatures up to 1600°C with low thermal expansion (7.5 ×10⁻⁶/°C).

- Dimensional Control: Thread diameter tolerance ±0.1mm; fits global metric/imperial standards.

- Cleanroom Compatible: No metal ions or volatile contaminants in sensitive environments.

Alumina Ceramic Screws

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

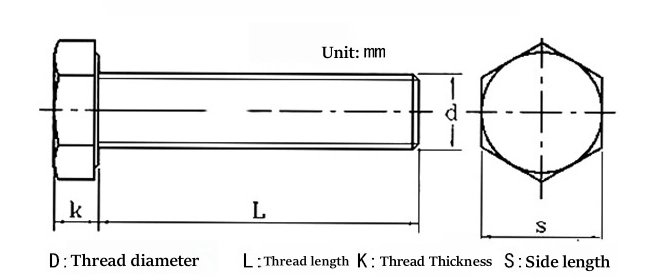

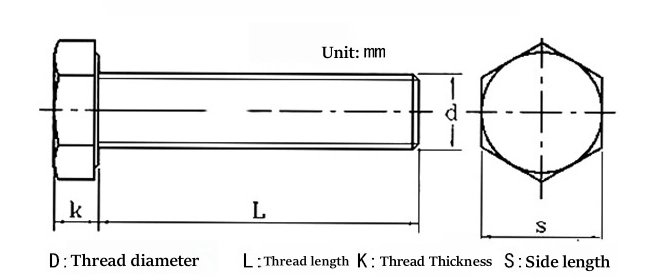

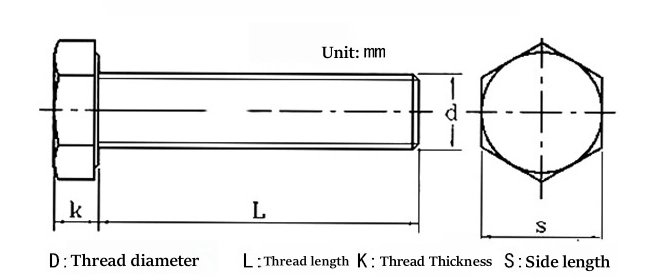

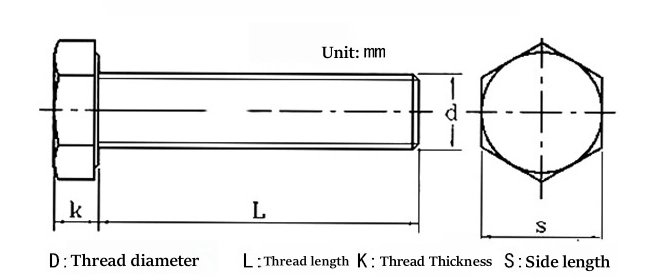

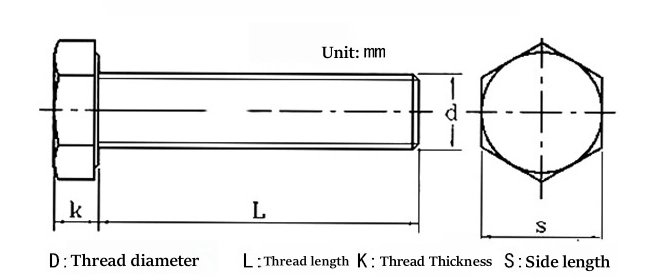

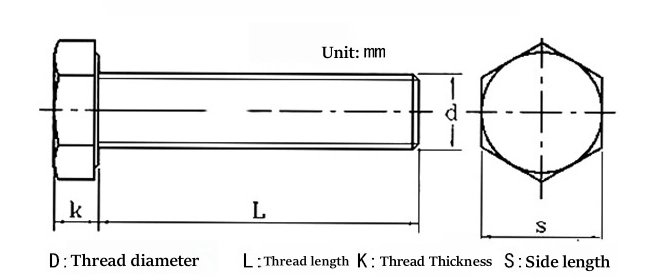

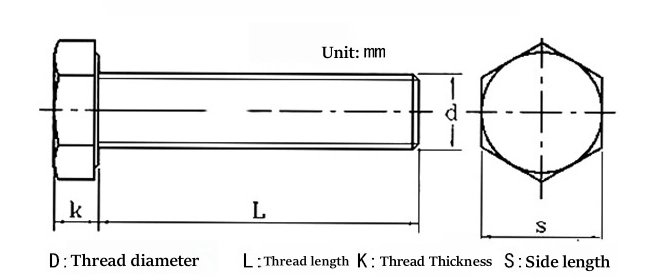

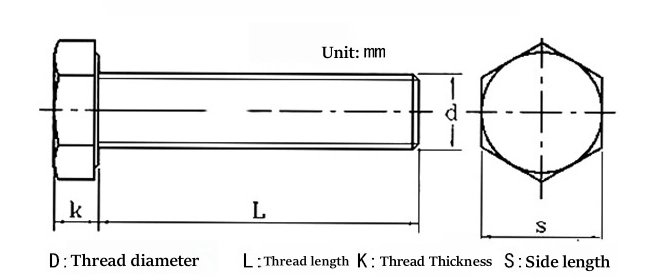

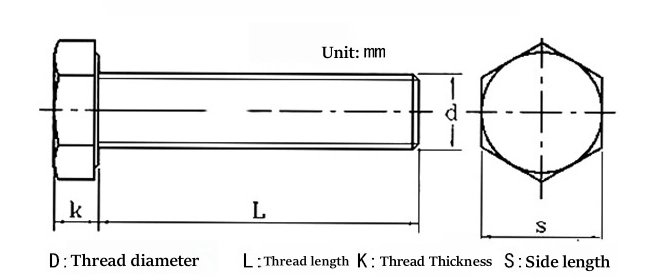

Alumina Screws Specifications

Type 1: M2 Alumina Screw and Bolt

| M2 Alumina Screw and Bolt | ||||

| Item No. | D(mm) | L (mm) | K (mm) | S (mm) |

| AT-YHL-LS001 | Flat Head with Single Slot Half-thread | 22 | 1.4 | 3.8 |

| AT-YHL-LS002 | Internal Hexagon | 14 | 1.9 | 3.8 |

| AT-YHL-LS003 | Flat Head with Single Slot | 10 | 1.4 | 3.8 |

| AT-YHL-LS004 | Cross-head Self-tapping Thread | 8 | 1.6 | 3.5 |

| AT-YHL-LS005 | Round Head with Cross-slot | 8 | 1.5 | 3.5 |

| AT-YHL-LS006 | External hHexagon | 6 | 1.6 | 3.9 |

| AT-YHL-LS007 | Countersunk Head with Cross-slot | 6 | / | 4.2 |

Type 2: M2.5 Alumina Screw and Bolt

| M2.5 Alumina Screw and Bolt | ||||

| Item No. | D(mm) | L (mm) | K (mm) | S (mm) |

| AT-YHL-LS017 | Countersunk Cross | 9 | / | 4.5 |

| AT-YHL-LS018 | 6 | / | 3.9 | |

Type 3: M3 Alumina Screw and Bolt

| M3 Alumina Screw and Bolt | ||||

| Item No. | D(mm) | L (mm) | K (mm) | S (mm) |

| AT-YHL-LS008 | External hHexagon | 10 | 3 | 5.5 |

| AT-YHL-LS009 | Internal Hexagon | 330 | 3 | 5.4 |

| AT-YHL-LS010 | Internal Hexagon | 20/25 | 3 | 5.4 |

| AT-YHL-LS011 | Internal Hexagon | 15 | 3 | 5.4 |

| AT-YHL-LS012 | Internal Hexagon | 10 | 3 | 5.4 |

| AT-YHL-LS013 | Internal Hexagon | 8 | 3 | 5.4 |

| AT-YHL-LS014 | Countersunk Head with Cross-slot | 15 | / | 5.2 |

| AT-YHL-LS015 | Countersunk Head with Cross-slot | 6 | / | 5.6 |

| AT-YHL-LS016 | Round Head with Cross-slot | 6.5 | 2.7 | 5.5 |

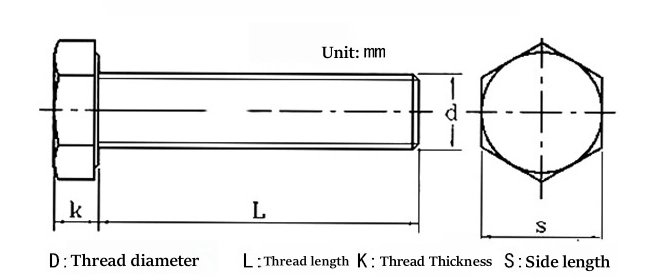

Type 4: M3.5 Alumina Screw and Bolt

| M3.5 Alumina Screw and Bolt | ||||

| Item No. | D(mm) | L (mm) | K (mm) | S (mm) |

| AT-YHL-LS019 | Countersunk Cross | 9 | / | 5.3 |

Type 5: M5 Alumina Screw and Bolt

| M5 Alumina Screw and Bolt | ||||

| Item No. | D(mm) | L (mm) | K (mm) | S (mm) |

| AT-YHL-LS033 | External hHexagon | 25 | 3.5 | 8 |

| AT-YHL-LS034 | External hHexagon | 20 | 3.6 | 8 |

| AT-YHL-LS035 | External hHexagon | 15 | 3.6 | 8 |

| AT-YHL-LS036 | External hHexagon | 10/12 | 3.6 | 7.6 |

| AT-YHL-LS037 | External hHexagon | 5 | 3.6 | 8 |

| AT-YHL-LS038 | Internal Hexagon | 35 | 4.7 | 7.8 |

| AT-YHL-LS039 | Internal Hexagon | 25 | 4.9 | 8.1 |

| AT-YHL-LS040 | Internal Hexagon | 20 | 4.9 | 8.1 |

| AT-YHL-LS041 | Internal Hexagon | 15 | 4.9 | 8.1 |

| AT-YHL-LS042 | Internal Hexagon | 10/12 | 4.9 | 8.1 |

| AT-YHL-LS043 | Internal Hexagon | 5 | 4.9 | 8.1 |

| AT-YHL-LS044 | Round Head with Cross-slot | 25 | / | 8.6 |

| AT-YHL-LS045 | Round Head with Cross-slot | 20 | / | 8.5 |

| AT-YHL-LS046 | Round Head with Cross-slot | 12 | / | 8.5 |

| AT-YHL-LS047 | Round Head with Internal Hexagon | 25 | 2.6 | 9.3 |

| AT-YHL-LS048 | Round Head with Internal Hexagon | 20 | 2.8 | 9.4 |

| AT-YHL-LS049 | Round Head with Internal Hexagon | 12 | 2.8 | 8.6 |

| AT-YHL-LS050 | Round Head with Single Slot | 10 | 3.4 | 7.9 |

| AT-YHL-LS051 | Countersunk Head with Cross-slot | 10 | / | 8.9 |

| AT-YHL-LS052 | Round Head with Single Slot and Hole | 6/15 | 3 | 10 |

| AT-YHL-LS053 | Blind Head with Internal Hexagon | 10 | / | / |

| AT-YHL-LS054 | Blind Head with Internal Hexagon | 6 | / | / |

Type 6: M6 Alumina Screw and Bolt

| M6 Alumina Screw and Bolt | ||||

| Item No. | D(mm) | L (mm) | K (mm) | S (mm) |

| AT-YHL-LS055 | External hHexagon | 55 | 5.2 | 9.7 |

| AT-YHL-LS056 | External hHexagon | 40 | 4.3 | 9.6 |

| AT-YHL-LS057 | Internal Hexagon | 40 | 5.8 | 9.8 |

| AT-YHL-LS058 | Internal Hexagon | 25 | 5.9 | 10 |

| AT-YHL-LS059 | Internal Hexagon | 16 | 5.9 | 10 |

| AT-YHL-LS060 | Countersunk Head with Cross-slot | 40 | / | 12 |

| AT-YHL-LS061 | External Hexagon with Single Slot | 25 | 3.9 | 9.8 |

| AT-YHL-LS062 | Round Head with Single Slot and Hole | 20 | 4.8 | 10 |

| AT-YHL-LS063 | Countersunk Head with Internal Hexagon | 15 | / | 9.8 |

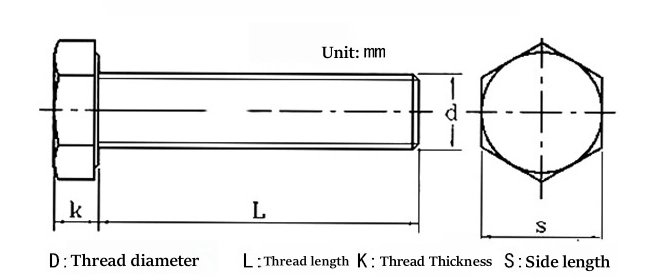

Type 7: M8 Alumina Screw and Bolt

| M8 Alumina Screw and Bolt | ||||

| Item No. | D(mm) | L (mm) | K (mm) | S (mm) |

| AT-YHL-LS064 | External hHexagon | 70 | 5.6 | 14 |

| AT-YHL-LS065 | External hHexagon | 50 | 4.5 | 11.7 |

| AT-YHL-LS066 | External hHexagon | 35 | 5.3 | 12.9 |

| AT-YHL-LS067 | External hHexagon | 25 | 5.3 | 12.9 |

| AT-YHL-LS068 | Internal Hexagon | 50 | 7.6 | 12.3 |

| AT-YHL-LS069 | Internal Hexagon | 35 | 7.9 | 12.3 |

| AT-YHL-LS070 | Flat Head with Internal Hexagon | 30 | / | 13.8 |

| AT-YHL-LS071 | Countersunk Head with Cross-slot | 20 | / | 14.2 |

Type 9: M10 Alumina Screw and Bolt

| M10 Alumina Screw and Bolt | ||||

| Item No. | D(mm) | L (mm) | K (mm) | S (mm) |

| AT-YHL-LS072 | External hHexagon | 70 | 7 | 16.8 |

| AT-YHL-LS073 | External hHexagon | 35 | 6.6 | 16.6 |

| AT-YHL-LS074 | Internal Hexagon | 50 | 9 | 14.8 |

| AT-YHL-LS075 | Internal Hexagon | 35 | 9.1 | 14.8 |

Type 10: M12 Alumina Screw and Bolt

| M12 Alumina Screw and Bolt | ||||

| Item No. | D(mm) | L (mm) | K (mm) | S (mm) |

| AT-YHL-LS076 | External hHexagon | 75 | 8.1 | 18.8 |

| AT-YHL-LS077 | External hHexagon | 50 | 10.2 | 18.8 |

| AT-YHL-LS078 | External hHexagon | 35 | 10.1 | 18.4 |

| AT-YHL-LS079 | External hHexagon | 25 | 10.3 | 18.4 |

| AT-YHL-LS080 | External hHexagon | 15 | 10 | 21.2 |

| AT-YHL-LS081 | Internal Hexagon | 50 | 10.5 | 17.2 |

| AT-YHL-LS082 | Internal Hexagon | 35/25 | 10.4 | 17.1 |

| AT-YHL-LS083 | Internal Hexagon | 15 | 12.2 | 18.1 |

| AT-YHL-LS084 | Internal Hexagon | 14 | 12.2 | 18 |

Type 11: M14 Alumina Screw and Bolt

| M14 Alumina Screw and Bolt | ||||

| Item No. | D(mm) | L (mm) | K (mm) | S (mm) |

| AT-YHL-LS085 | External hHexagon | 80 | 10 | 22 |

| AT-YHL-LS086 | External hHexagon | 50 | 7.6 | 21.9 |

| AT-YHL-LS087 | External hHexagon | 40 | 9.9 | 21 |

Type 12: M16 Alumina Screw and Bolt

| M16 Alumina Screw and Bolt | ||||

| Item No. | D(mm) | L (mm) | K (mm) | S (mm) |

| AT-YHL-LS088 | External hHexagon | 100 | 9.2 | 24.2 |

| AT-YHL-LS089 | External hHexagon | 70 | 9.2 | 24.2 |

| AT-YHL-LS090 | External hHexagon | 40 | 9.2 | 24.2 |

Alumina Ceramic Screws Packaging

- Each screw separated in soft pouches or compartment boxes to avoid edge chipping.