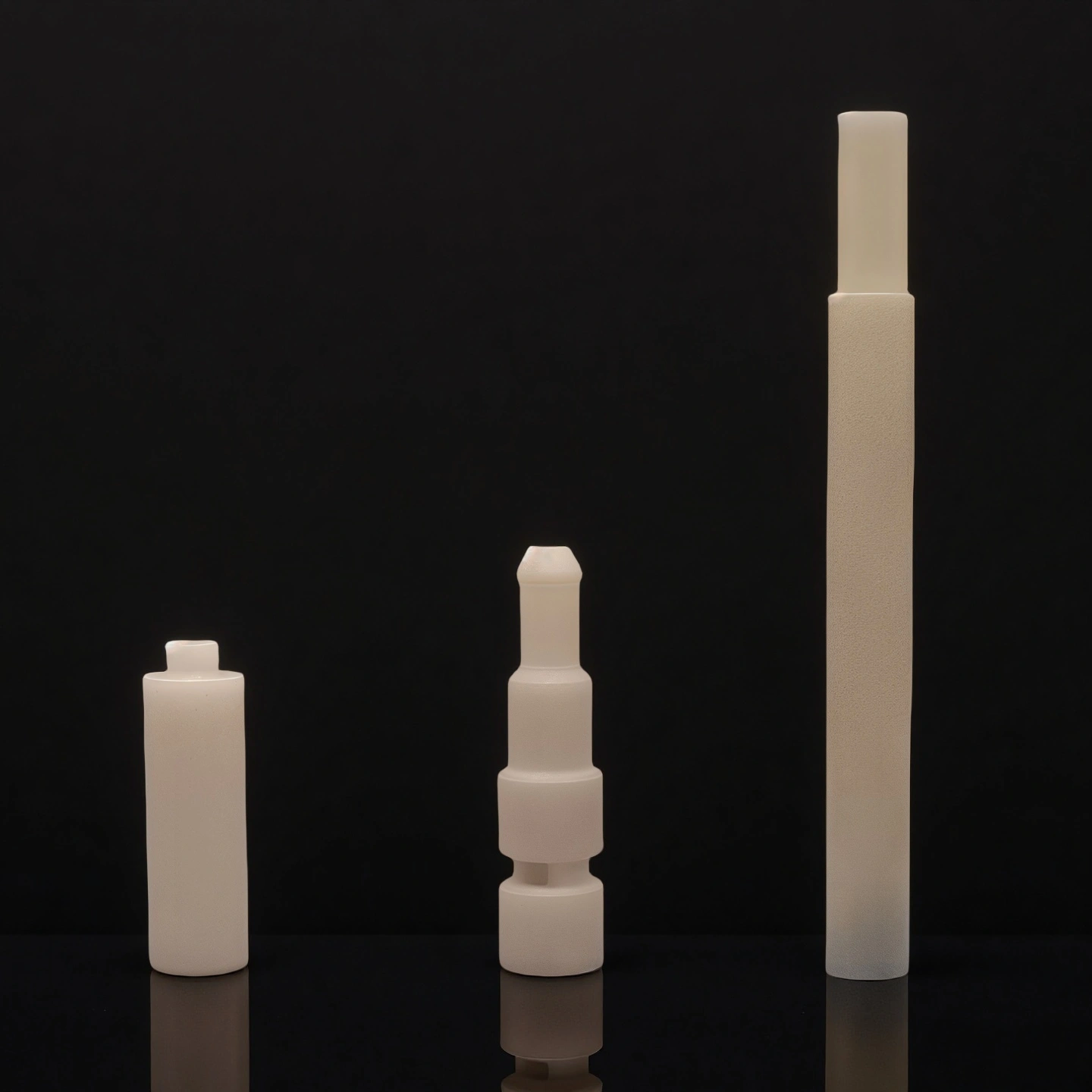

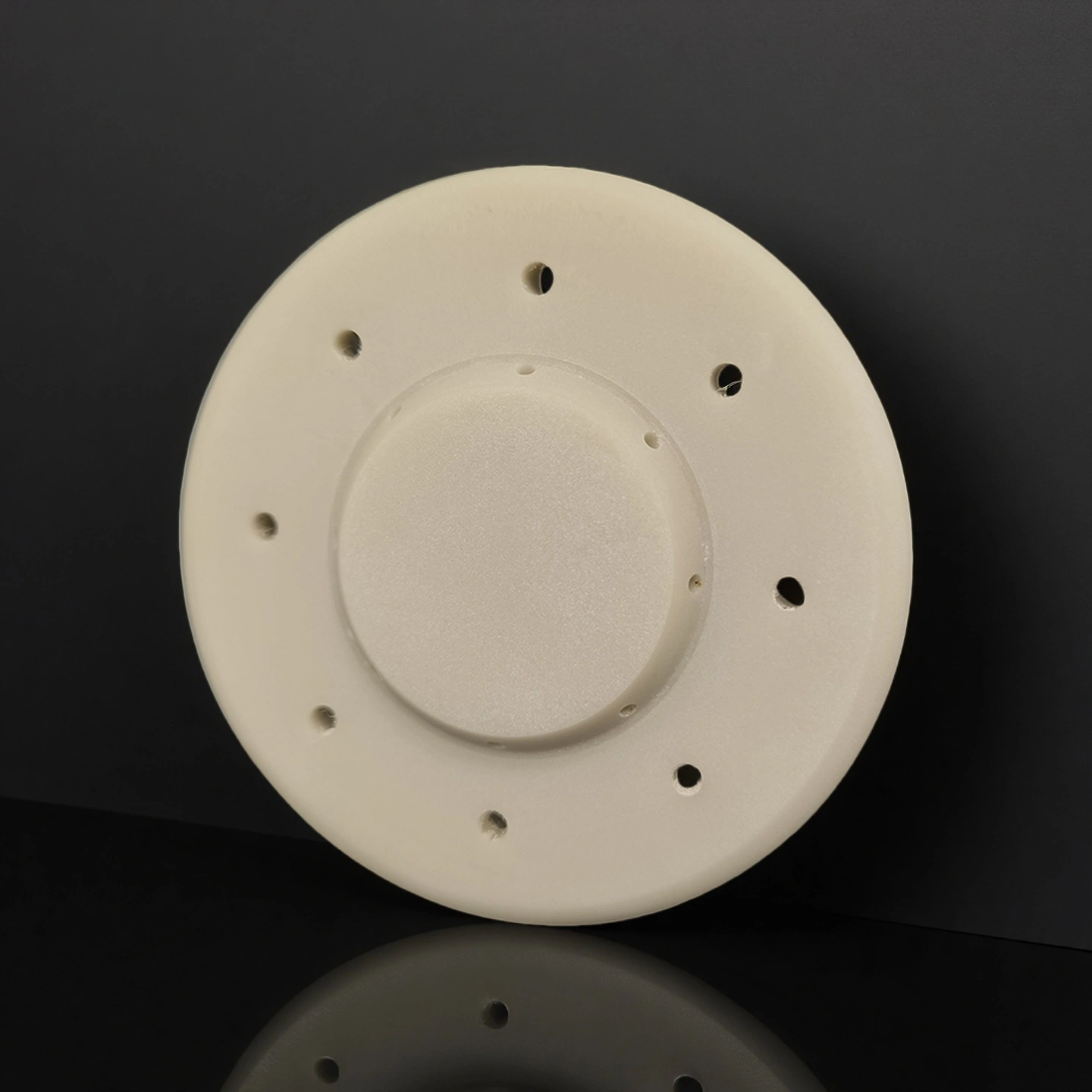

Aluminum nitride ceramic nozzle is a precision-machined flow component made from aluminum nitride (AlN) ceramic, used to inject, meter or distribute gases or liquids in high-temperature and electrically demanding environments. It combines high thermal conductivity with strong electrical insulation, so it can remove heat from the nozzle tip while keeping nearby electrodes or sensors electrically isolated.

Aluminum Nitride Ceramic Nozzle Benefits

-

Stable Flow Through Tight Orifice Control

Orifice diameters can be machined down to around 0.2–1.5 mm with tight tolerances, helping you achieve repeatable gas or liquid flow profiles in semiconductor and laser systems.

-

Heat-Loaded Zones Stay Under Control

The aluminum nitride ceramic nozzle conducts heat away from the hot spot around the orifice, reducing local overheating in high-power laser or plasma processes and supporting consistent process temperature.

-

Electrical Isolation at the Injection Point

The nozzle body can be used as an electrically insulating feed path in high-voltage or RF environments, helping to isolate electrodes or charged components from metal manifolds.

-

Geometry Tuned to Your Process

Straight, tapered, stepped or multi-hole aluminum nitride ceramic nozzles can be designed to set spray angle, jet velocity or gas distribution pattern without major changes to your upstream plumbing.

-

Durable in Corrosive and High-Temperature Atmospheres

The aluminum nitride ceramic nozzle resists many process gases, molten metals and reactive atmospheres at elevated temperature, which helps maintain nozzle shape and internal dimensions over multiple production runs.

AlN Nozzle Properties

| Property Content | Unit | Unit | ALN-170 | ALN-200 | ALN-230 |

| Basic Properties | Color | gray | light yellow | light yellow | |

| Density | g/cm³ | 3.2-3.3 | 3.2-3.3 | 3.2-3.3 | |

| Surface Roughness | μm | 0.2-0.75 | 0.2-0.75 | 0.2-0.8 | |

| Camber | length ‰ | ≤3‰ | ≤3‰ | ≤3‰ | |

| Hardness | HV | 1100 | 1100 | 1100 | |

| Thermal Properties | Max Operating Temperature | °C | 1100 | 1100 | 1100 |

| Thermal Conductivity | W/m·K | 170-190 | 190-220 | 220-230 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(20-400°c) | 4-5 | 4-5 | 4-5 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(400-800°c) | 5-6 | 5-6 | 5-6 | |

| Mechanical Properties | Flexural Strength | MPa | 300-400 | 350-450 | 400-500 |

| Tensile Strength | MPa | 200-300 | 250-350 | 280-380 | |

| Compressive Strength | MPa | 2000-3000 | 2200-3200 | 2500-3500 | |

| Electrical properties | Dielectric Constant | at 1MHz | 8-9 | 8-9 | 8-9 |

| Dielectric strength | KV/mm | ≥15 | ≥15 | ≥15 | |

| Volume resistivity | 20℃ Ω.cm | ≥1014 | ≥1014 | ≥1014 |

Aluminium Nitride Ceramic Nozzle Specifications

| Item No. | Diameter (mm) | Thickness (mm) | Purity |

| AT-AIN-PZ001 | Customize | ||

Aluminum Nitride Nozzle Packaging

- Each aluminum nitride ceramic nozzle is individually packed in soft trays or slots to avoid chipping at the orifice and sealing faces.