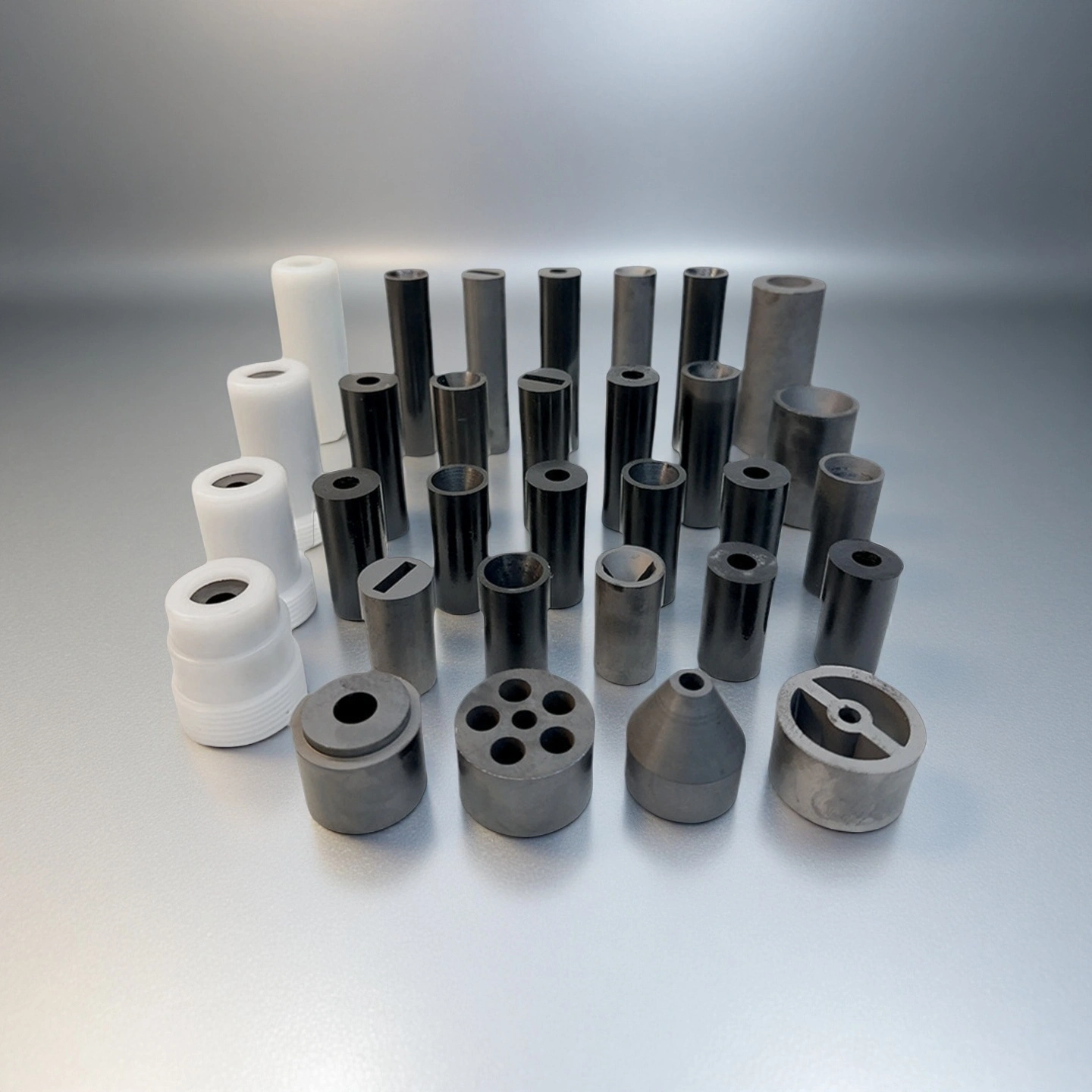

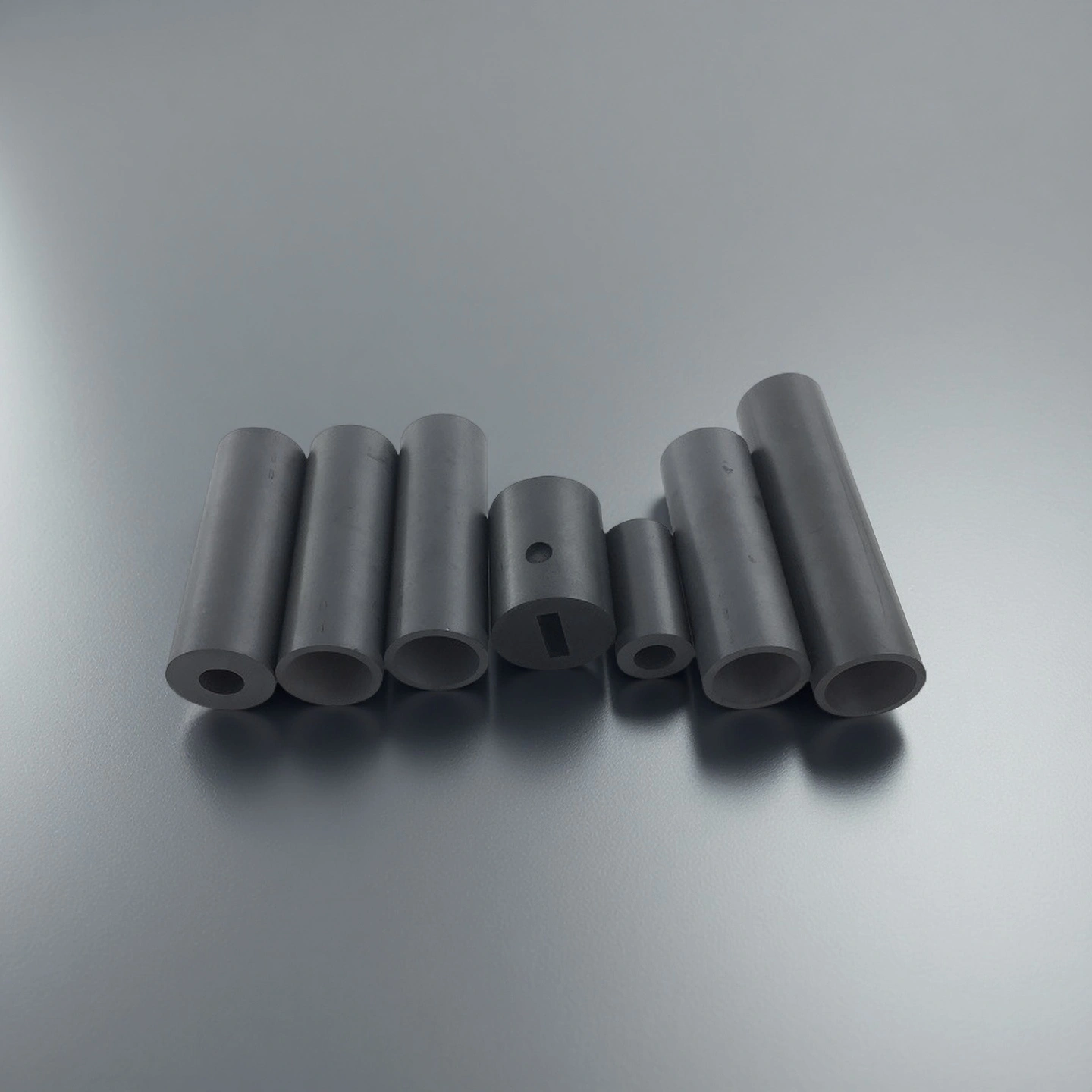

Boron Carbide Sandblasting Nozzle is a high-wear-resistant nozzle made from boron carbide (B₄C) — an advanced ceramic known for exceptional hardness and low density. It is one of the key components used in abrasive blasting machines, where compressed air propels abrasive media to clean, polish, or prepare surfaces.

Benefits of Boron Carbide Nozzles

- Stable spray width from optimized venturi and exit angle to maintain pattern on large surfaces.

- Wear-resistant bore for abrasive media (Al₂O₃, SiC) to reduce change-out frequency.

- Weight-optimized jacket (aluminum or PU) to lower operator fatigue during long passes.

- Interface precision—repeatable thread and sealing face for tight holder coupling.

- Dimensional consistency across batches to support multi-gun setups and OEM kits.

Boron Carbide Sandblasting Nozzles Properties

| B₄C Propertites | |

| Hot Pressed Sintered B4C | |

| Purity of B₄C | ≥90 |

| Flexture strength (MPa) | 480 |

| Elastic Modulus (GPa) | 450 |

| Poisson's ratio | 0.21 |

| Compressive strength (MPa) | 2500 |

| Hardness (GPa) | ≥24 |

| Fracture toughness (MPa*m1/2) | 4 |

| Maximum working temperature (℃) | 1600 |

| Thermal conductivity (W/m*K) | 150 |

| Thermal expansion coefficient (/℃) | 4.4*10-6 |

| Thermal shock resistance (ΔT ℃) | 400 |

Specifications of Boron Carbide Nozzles

| Model | Size (mm) | Bore Diameter (mm) | Mounting Type | Working Temperature | Working Pressure (MPa) | Applicable Media |

| AT-BC-PZ1001 | 15×55×8 | 8 | Slot-mounted | ≤600 °C | 2.2 | All types of blasting abrasives |

| AT-BC-PZ1002 | 20×35×6 | 6 | Sleeve / Rubber sleeve / Snap-fit | ≤600 °C | 2.2 | All types of blasting abrasives |

| AT-BC-PZ1003 | 20×35×8 | 8 | Sleeve / Rubber sleeve / Snap-fit | ≤600 °C | 2.2 | All types of blasting abrasives |

| AT-BC-PZ1004 | 20×35×10 | 10 | Sleeve / Rubber sleeve / Snap-fit | ≤600 °C | 2.2 | All types of blasting abrasives |

| AT-BC-PZ1005 | 20×45×6 | 6 | Sleeve / Rubber sleeve / Snap-fit | ≤600 °C | 2.2 | All types of blasting abrasives |

| AT-BC-PZ1006 | 20×45×8 | 8 | Sleeve / Rubber sleeve / Snap-fit | ≤600 °C | 2.2 | All types of blasting abrasives |

| AT-BC-PZ1007 | 20×45×10 | 10 | Sleeve / Rubber sleeve / Snap-fit | ≤600 °C | 2.2 | All types of blasting abrasives |

| AT-BC-PZ1008 | 20×60×6 | 6 | Sleeve / Rubber sleeve / Snap-fit | ≤600 °C | 2.2 | All types of blasting abrasives |

| AT-BC-PZ1009 | 20×60×8 | 8 | Sleeve / Rubber sleeve / Snap-fit | ≤600 °C | 2.2 | All types of blasting abrasives |

| AT-BC-PZ1010 | 20×60×10 | 10 | Sleeve / Rubber sleeve / Snap-fit | ≤600 °C | 2.2 | All types of blasting abrasives |

| AT-BC-PZ1011 | 20×80×6 | 6 | Sleeve / Rubber sleeve / Snap-fit | ≤600 °C | 2.2 | All types of blasting abrasives |

| AT-BC-PZ1012 | 20×80×8 | 8 | Sleeve / Rubber sleeve / Snap-fit | ≤600 °C | 2.2 | All types of blasting abrasives |

| AT-BC-PZ1013 | 20×80×10 | 10 | Sleeve / Rubber sleeve / Snap-fit | ≤600 °C | 2.2 | All types of blasting abrasives |

| AT-BC-PZ1014 | 26×83×8 | 8 | Sleeve-mounted | ≤600 °C | 2.2 | All types of blasting abrasives |

| AT-BC-PZ1015 | 26×83×12 | 12 | Sleeve-mounted | ≤600 °C | 2.2 | All types of blasting abrasives |

| AT-BC-PZ1016 | 29×10×77 | 10 | Sleeve-mounted | ≤600 °C | 2.2 | All types of blasting abrasives |

| AT-BC-PZ1017 | 31×6.5×1.8 | 1.8 | Snap-fit | ≤600 °C | 2.2 | All types of blasting abrasives |

| AT-BC-PZ1018 | 20×35×3 | 3 | Sleeve / Rubber sleeve / Snap-fit | ≤600 °C | 2.2 | All types of blasting abrasives |

| AT-BC-PZ1019 | 20×35×4 | 4 | Sleeve / Rubber sleeve / Snap-fit | ≤600 °C | 2.2 | All types of blasting abrasives |

| AT-BC-PZ1020 | 20×35×12 | 12 | Snap-fit | ≤600 °C | 2.2 | All types of blasting abrasives |

| AT-BC-PZ1021 | 20×45×12 | 12 | Snap-fit | ≤600 °C | 2.2 | All types of blasting abrasives |

| AT-BC-PZ1022 | 20×60×12 | 12 | Snap-fit | ≤600 °C | 2.2 | All types of blasting abrasives |

| AT-BC-PZ1023 | 20×80×12 | 12 | Snap-fit | ≤600 °C | 2.2 | All types of blasting abrasives |

Boron Carbide Blast Nozzle Packaging

Each nozzle is packed in an individual shock-proof box with silica gel and protected caps on both ends.