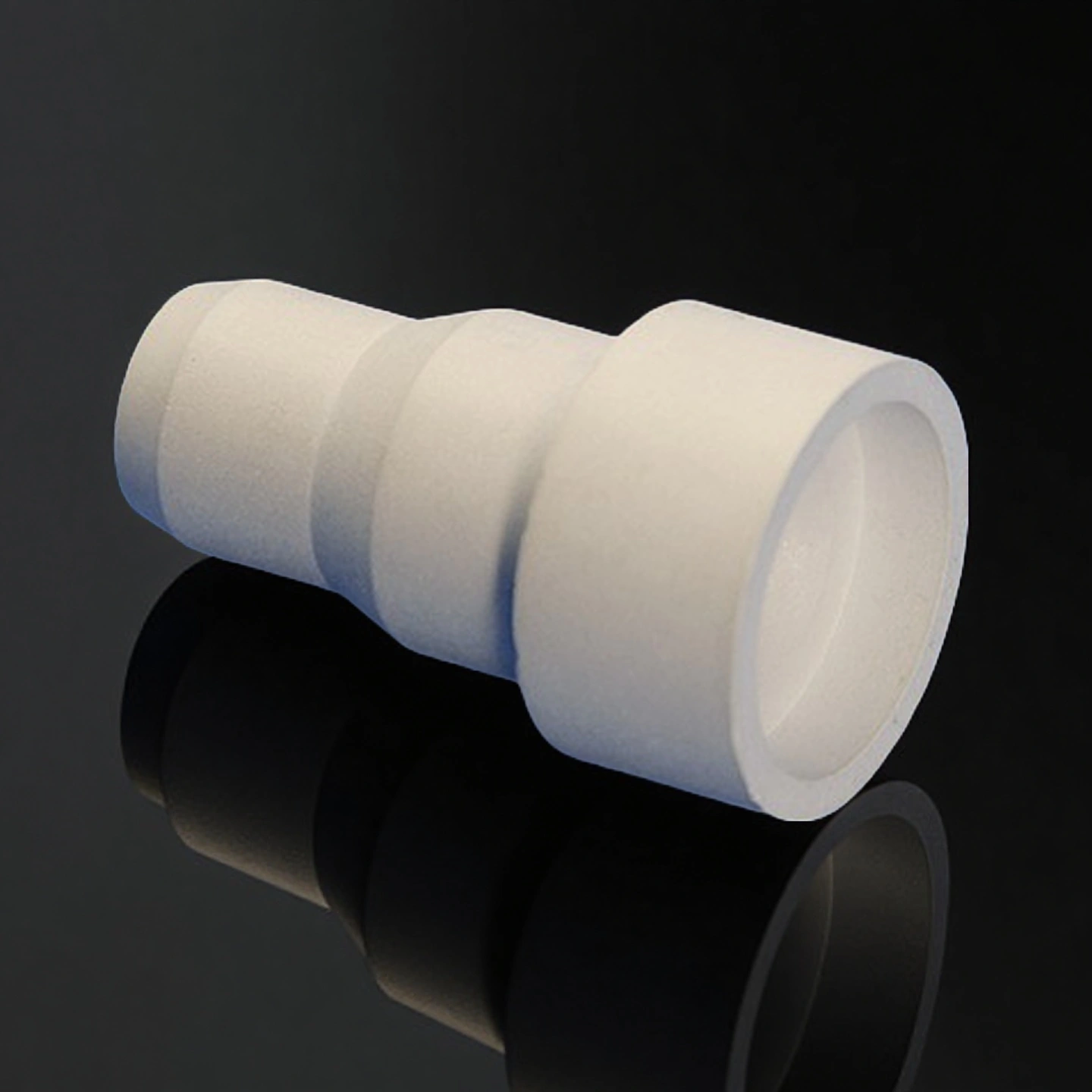

Boron nitride (BN) ceramic nozzle is a precision-machined, high-temperature nozzle made from hot-pressed hexagonal BN (sometimes BN-ZrO₂ composite, a.k.a. ZSBN). It’s used to shape and control gas or molten-metal jets in processes such as metal powder atomization, aluminum/copper casting, thermal spray, and protective-atmosphere equipment. BN’s surface is non-wetting to most molten metals, so the orifice stays clean, resists clogging, and holds geometry under heat.

Boron Nitride Ceramic Nozzle Benefits

1. Non-Wetting to Molten Metals

Hot-pressed BN is chemically inert to molten Al, Zn, and Cu alloys. It prevents adhesion and clogging, keeping the orifice clean and extending stable spray operation by 70 %+ compared with alumina or SiC nozzles.

2. High Dimensional Accuracy

CNC-machined to ±0.05 mm tolerance and Ra < 0.4 µm surface finish, ensuring uniform jet geometry and consistent powder or droplet size in atomization and casting systems.

3. Thermal Shock Resistance

Withstands rapid temperature changes up to 800 °C / min without cracking. The BN crystal structure disperses stress effectively during heating and quenching cycles.

4. Long Service Life

Delivers 3–5 × the operational life of conventional ceramic nozzles, reducing downtime, replacement frequency, and overall maintenance cost in continuous casting lines.

5. Stable Under Vacuum/Inert Atmospheres

Maintains full mechanical and chemical stability up to 1800 °C with no gas release, ideal for vacuum furnaces, atomization chambers, and inert-gas casting environments.

Boron Nitride Ceramic Nozzle Properties

|

Property |

Unit |

Pyrolytic Boron Nitride |

Hot Pressed Boron Nitride |

|

Purity |

|

99.99% |

99.50% |

|

Density |

g/cm3 |

2.15-2.19 |

1.96-2 |

|

Hardness |

HV0.5 |

651 |

62 |

|

Volume resistivity |

Ohm*cm |

2*1014 |

1.2*1014 |

|

Dielectric strength |

kV/mm |

55 |

76 |

|

Maximum working temperature |

℃ |

1000 (air), 2300 (vacuum) |

900 (air), 1850 (vacuum) |

|

Bending strength |

MPa |

173 (A direction) |

310 |

|

Thermal conductivity |

W/m*K |

60 (A direction) |

55 |

|

Tensile strength |

MPa |

112 (A direction) |

110 |

|

Thermal expansion coefficient |

/℃ |

6*10-7 |

1.8*10-6 |

|

Compressive strength |

MPa |

154 (A direction) |

120 |

BN Ceramic Nozzle Specifications

|

Amorphous and Nanocrystalline BN Ceramic Nozzle |

|

Item No. |

Outer Diameter(mm) |

Inner Diameter(mm) |

|

AT-BNC-PZ1001 |

Customize |

|

Powder metallurgy BN Ceramic Nozzle |

|

Item No. |

Outer Diameter(mm) |

Inner Diameter(mm) |

|

AT-BN-PZ1001 |

Customize |

Boron Nitride Nozzle Packaging

- Each nozzle is individually packed in anti-static foam-lined boxes.

Boron Nitride Nozzle Applications

Boron nitride ceramic nozzles are widely applied in metal atomization, continuous alloy casting, and additive manufacturing, where extreme temperatures, reactive melts, and high gas flow rates demand precision and chemical stability. ADCERAX’s BN nozzles provide consistent performance, reduced downtime, and measurable efficiency gains across diverse industrial processes.

-

Metal Powder Atomization Industry

✅Key Advantages

1. Jet Stability Under High Pressure (≤ 6 MPa): Maintains laminar spray and uniform particle size distribution during high-pressure atomization with nitrogen or argon gas.

2. Reduced Metal Build-Up: The non-wetting BN surface lowers adhesion of aluminum or magnesium alloys, decreasing nozzle clogging by up to 70 % and improving process continuity.

3. Extended Lifetime: Hot-pressed BN nozzles maintain geometry and flow path integrity for 20 – 60 hours of continuous operation, with minimal erosion or surface degradation.

4. Improved Powder Quality: Consistent spray angle and orifice precision reduce fines content and narrow particle size distribution (D₅₀ variation < 8 %).

5. Easy Maintenance: Smooth inner surface allows post-run cleaning without mechanical abrasion or acid treatment.

✅ Problem Solved

A German metal powder manufacturer producing aluminum-based alloys experienced frequent clogging and flow deviation using alumina nozzles, resulting in three days of production loss (~ USD 50,000). After switching to ADCERAX BN ceramic nozzles, their nozzle replacement cycle increased from 18 hours to over 50 hours, and atomized powder uniformity improved by 22 %, verified through internal laser diffraction analysis.

-

Aluminum & Copper Alloy Casting

✅Key Advantages

1. Non-Wetting to Molten Alloys: Prevents oxide build-up and stream deviation, maintaining precise metal flow control.

2. Excellent Thermal Shock Endurance: Withstands repeated contact with 700–1000 °C molten aluminum without cracking or delamination.

3. Dimensional Stability: Orifice tolerance held within ± 0.05 mm, ensuring steady casting speed and smooth flow profile.

4. Reduced Downtime: Longer nozzle service life lowers replacement frequency and improves furnace uptime.

5. Chemical Inertness: Resists reaction with fluxes, reducing inclusions in cast products and improving metal surface quality.

✅ Problem Solved

An Italian continuous casting equipment OEM reported daily nozzle failure when using SiC materials under molten aluminum exposure.

After switching to ADCERAX BN nozzles, nozzle lifespan increased by a factor of 4, cutting weekly replacements to one. Casting defects caused by oxide contamination dropped by 30 %, and the plant achieved a smoother laminar flow profile verified through inline monitoring.

-

Additive Manufacturing & Thermal Spray

✅Key Advantages

1. Precision Feed Control: Maintains stable powder or gas delivery for metal 3D printing, plasma, and HVOF spray systems.

2. Electrical Insulation: Prevents arcing in plasma or induction-based nozzles, preserving stable plasma columns and uniform coating texture.

3. High Temperature Stability (≤ 1800 °C): Performs under inert or vacuum conditions without gas release, ensuring clean deposition environments.

4. Enhanced Surface Finish: Polished BN surface minimizes turbulence and maintains laminar gas flow during spray coating.

5. Custom Geometry Flexibility: Supports fine orifice and multi-jet designs for controlled spray pattern shaping.

✅ Problem Solved

A U.S. additive manufacturing powder supplier experienced inconsistent powder feed rates and frequent nozzle erosion in their plasma atomization system.

After integrating ADCERAX BN ceramic nozzles, erosion depth after 100 cycles was < 0.1 mm, and process downtime dropped by 35 %. The resulting printed parts showed improved layer density and smoother surface finish, verified by optical profilometry.

Boron Nitride Ceramic Nozzle Usage Instructions

Proper installation and maintenance of boron nitride ceramic nozzles ensure optimal flow precision, long service life, and consistent product quality in high-temperature atomization and casting systems. Follow the guidelines below to achieve the best operational performance.

-

Installation

1. Verify orifice alignment and seating flatness before tightening. Misalignment can cause off-axis gas flow or uneven atomization.

2. Use non-metallic tools (ceramic or polymer tips) on nozzle edges to prevent micro-cracks during setup.

3. Apply even torque across flange or thread connections; typical recommended torque ≤ 5 Nm for small nozzles.

4. Check seal integrity and gasket condition before operation—essential for vacuum or inert-gas atomization systems.

5. If mounting multiple nozzles, ensure equal spacing and parallel orientation to maintain uniform spray cone geometry.

-

Operation

1. Gradual Heating: Increase temperature at ≤ 10 °C/s to prevent thermal shock. Preheat slowly when switching from room temperature to 1000 °C+.

2. Controlled Gas Feed: Keep nitrogen or argon supply clean and dry (< 5 ppm moisture) to avoid oxidation residue on the inner surface.

3. Monitor Flow Pattern: Inspect spray alignment and droplet dispersion visually or via inline camera every 8–10 hours of operation.

4. Replacement Indicator: Replace the nozzle once erosion depth exceeds 0.1 mm or the atomization angle deviates by > 2°.

5. For long continuous runs (> 24 h), schedule short cooldown intervals to release accumulated thermal stress.

-

Storage

1. Store in a dry, temperature-controlled area below 40 % RH, ideally at 20–25 °C.

2. Keep nozzles sealed in moisture-proof bags with silica gel to avoid surface oxidation.

3. Stack nozzles horizontally with foam interleaves to prevent edge deformation or chipping.

4. Label each item with part number, batch, and last inspection date for traceability.

-

Cleaning & Maintenance

1. Clean after each run using compressed dry nitrogen or a soft bristle brush; never use metal picks or abrasive cloths.

2. For metal residue, warm to 400–500 °C in inert gas to loosen buildup, then purge.

3. Avoid acidic or alkaline solutions; BN reacts with strong oxidizers and hydroxides.

4. Before reuse after long storage (> 3 months), preheat to 200–300 °C for 30 min to remove absorbed moisture.

5. Record operation cycles in maintenance logs to predict replacement intervals.

-

Common User Errors & Recommended Solutions

1. Over-tightening during installation → micro-crack formation

Apply torque within design limits (≤ 5 Nm). Inspect seating surface flatness before tightening.

2. Sudden cooling after operation → thermal fracture

Always allow controlled furnace cooling below 200 °C before removal; avoid direct air quenching.

3. Exceeding gas-pressure limit → accelerated erosion

Operate strictly within rated working pressure ≤ 6 MPa. High gas velocity shortens lifespan.

4. Contact with moisture or flux chemicals → surface degradation

Use inert storage and avoid flux vapors near nozzle assemblies.

5. Improper alignment → unstable atomization cone

Check coaxiality and alignment after each installation; angular deviation should remain < 0.5°.