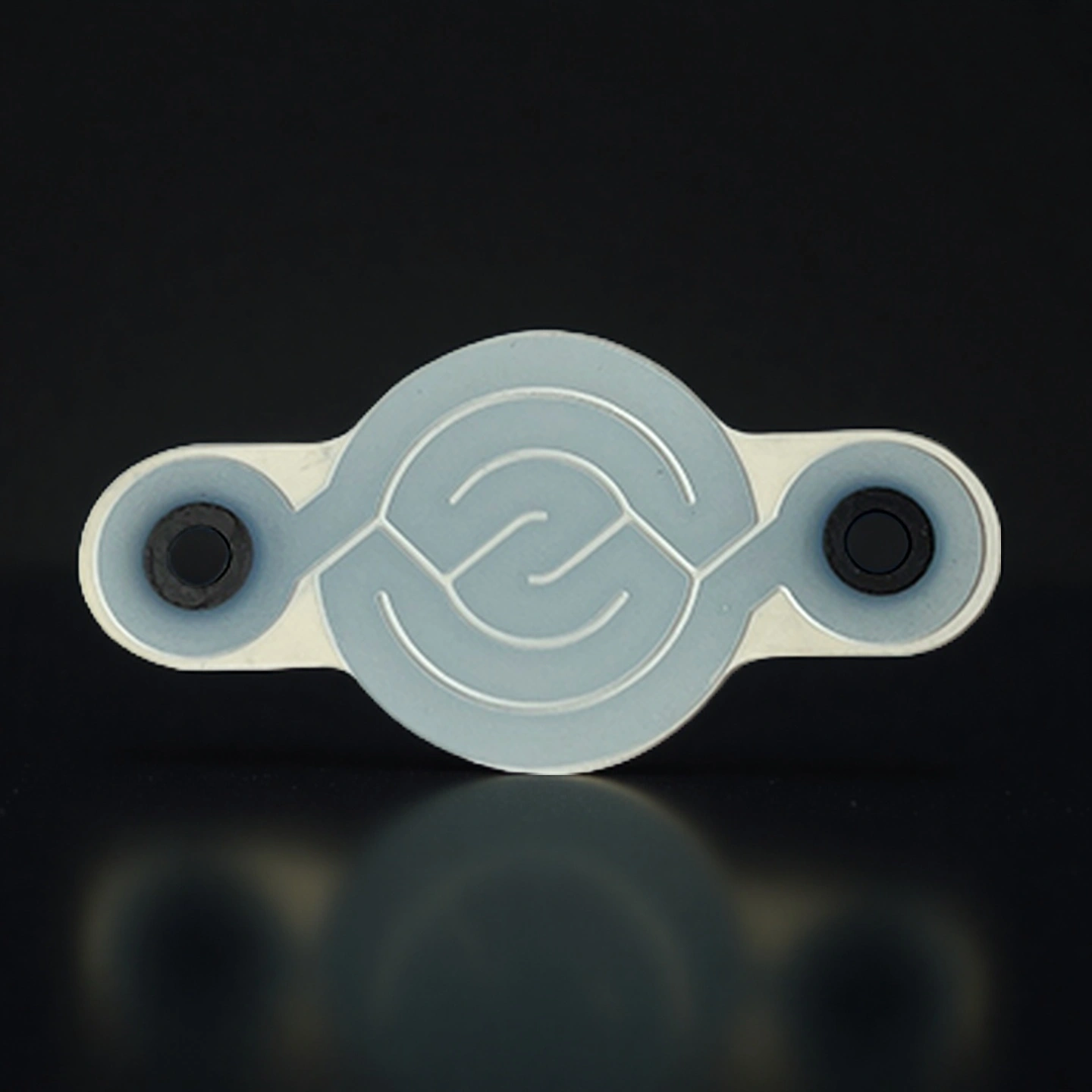

Boron Nitride Heater is a composite heating element designed for precision temperature control in UHV environments. Using pyrolytic boron nitride as the dielectric substrate and pyrolytic graphite as the resistive core, it combines excellent thermal conductivity, high insulation, and superior thermal shock resistance. It is widely integrated into PVD, ALD, and MBE chambers, as well as metallurgical sintering and high-temperature reactors.

Boron Nitride Heater Benefits

- Engineered Precision – Three-layer PBN–PG–PBN structure ensures stable, uniform heating. The anisotropic graphite core distributes heat evenly with minimal ΔT across the wafer.

- CVD-Fabricated Purity – Both PBN and PG layers are made by CVD, achieving 99.99% purity, fully dense microstructure, and ultra-low outgassing, suitable for UHV systems.

- High Thermal Shock Resistance – Withstands >200 K/s thermal ramp rate without cracking; maintains conductivity of 60–120 W/m·K through repeated cycles.

- Electrical Insulation – Dual PBN layers provide ≥ 1×10¹² Ω·cm resistivity and > 5 kV/mm dielectric strength for safe use in vacuum and plasma environments.

- Industrial Reliability – Proven lifespan of 1000 + cycles under high vacuum; resistance drift stays within ±1.5 %, ensuring consistent performance in semiconductor and metallurgical systems.

Boron Nitride Ceramic Heater Properties

| Property | Unit | Pyrolytic Boron Nitride | Hot Pressed Boron Nitride |

| Purity | 99.99% | 99.50% | |

| Density | g/cm3 | 2.15-2.19 | 1.96-2 |

| Hardness | HV0.5 | 651 | 62 |

| Volume resistivity | Ohm*cm | 2*1014 | 1.2*1014 |

| Dielectric strength | kV/mm | 55 | 76 |

| Maximum working temperature | ℃ | 1000 (air), 2300 (vacuum) | 900 (air), 1850 (vacuum) |

| Bending strength | MPa | 173 (A direction) | 310 |

| Thermal conductivity | W/m*K | 60 (A direction) | 55 |

| Tensile strength | MPa | 112 (A direction) | 110 |

| Thermal expansion coefficient | /℃ | 6*10-7 | 1.8*10-6 |

| Compressive strength | MPa | 154 (A direction) | 120 |

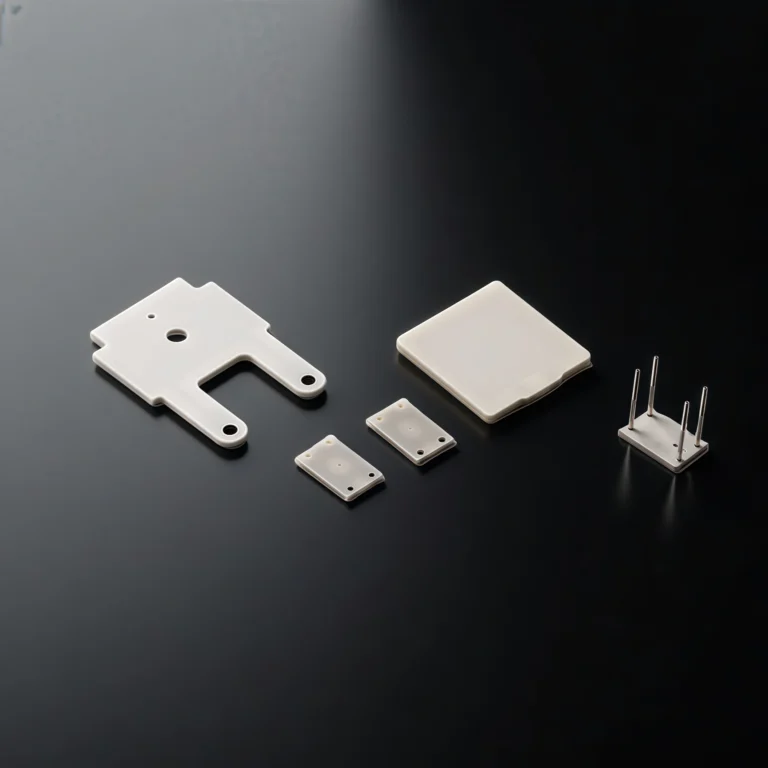

Boron Nitride Heater Specifications

| Boron Nitride Heater | ||

| Item No. | Diameter(mm) | Height (mm) |

| AT-BNC-H1001 | Customize | |

BN Heater Packaging

- Each heater is individually packed in anti-static pouches.

- Placed inside foam-cut trays with cavity support for all diameters.