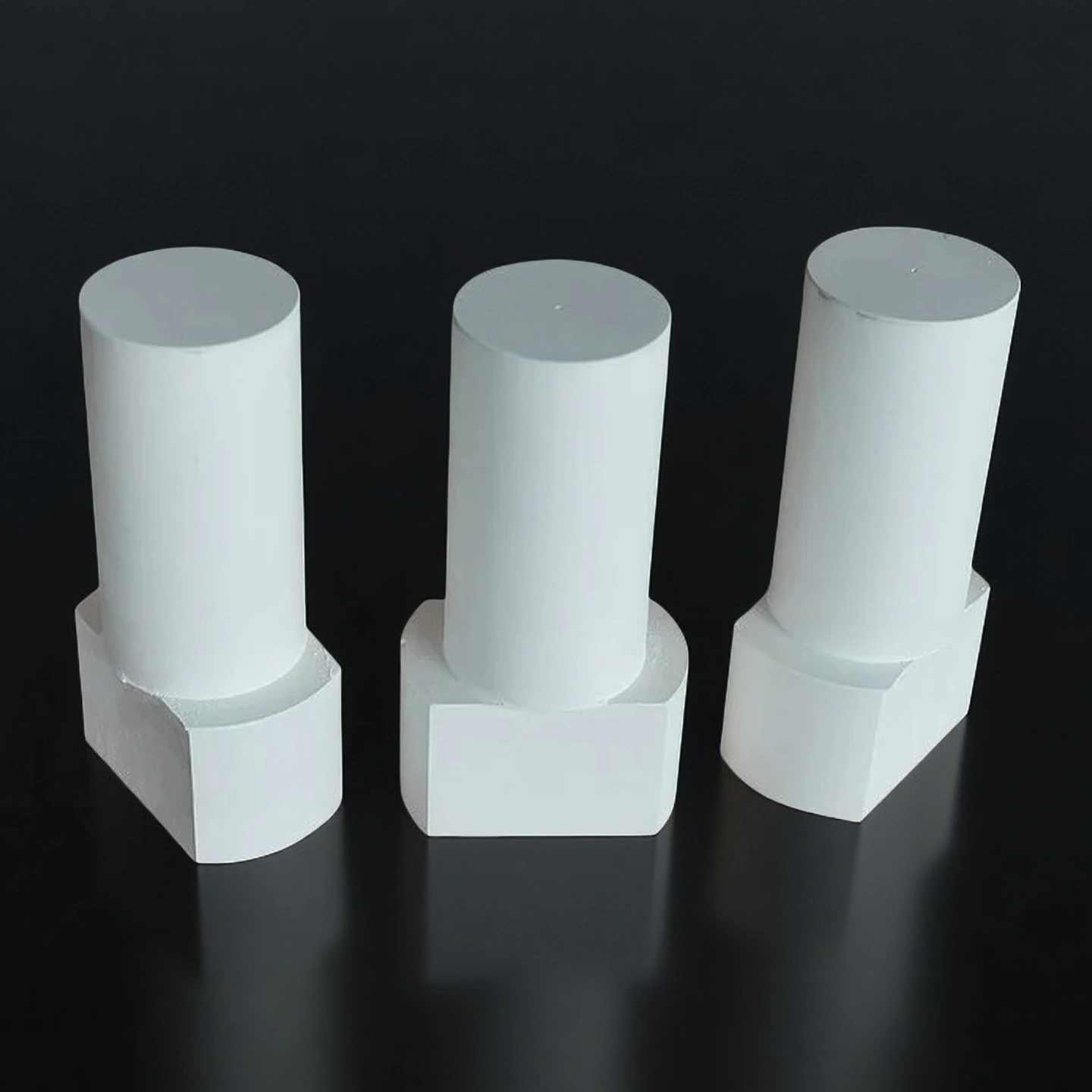

Boron Nitride Insulating Column is a precision-machined component made from hexagonal boron nitride (h-BN) ceramic, designed to provide electrical insulation and thermal stability inside high-temperature industrial equipment. It functions as a support post, spacer, or standoff in systems where both electrical isolation and high heat resistance are critical.

Boron Nitride Insulating Column Benefits

-

Non-wetting to Molten Al/Mg: BN columns resist metal adhesion and oxidation, reducing buildup on tooling and cutting clean-down time by up to 60%.

-

High Dielectric Stability at Temperature: Maintains >10¹² Ω·cm resistivity and strong insulation in vacuum and plasma zones, preventing arcing and leakage.

-

Machinable Precision Geometry: Allows ±0.05 mm tolerance with clean edges and threaded or stepped ends for consistent fixture alignment.

-

Thermal Shock Resistance: Low expansion (~1.0 × 10⁻⁶ /K) and good conductivity enable survival through repeated cycles to 1500 °C+.

-

Functional Surface Options: Polished, raw, or blasted finishes improve grip, fit, or electrical isolation based on assembly requirements.

BN Insulating Column Properties

| Property | Unit | Pyrolytic Boron Nitride | Hot Pressed Boron Nitride |

| Purity | 99.99% | 99.50% | |

| Density | g/cm3 | 2.15-2.19 | 1.96-2 |

| Hardness | HV0.5 | 651 | 62 |

| Volume resistivity | Ohm*cm | 2*1014 | 1.2*1014 |

| Dielectric strength | kV/mm | 55 | 76 |

| Maximum working temperature | ℃ | 1000 (air), 2300 (vacuum) | 900 (air), 1850 (vacuum) |

| Bending strength | MPa | 173 (A direction) | 310 |

| Thermal conductivity | W/m*K | 60 (A direction) | 55 |

| Tensile strength | MPa | 112 (A direction) | 110 |

| Thermal expansion coefficient | /℃ | 6*10-7 | 1.8*10-6 |

| Compressive strength | MPa | 154 (A direction) | 120 |

BN Insulating Column Specifications

| Item No. | Diameter (mm) | Thickness (mm) | Purity |

| AT-BN-LS1001 | Customize | ||

BN Ceramic Insulating Column Packaging

- Individually packed in anti-static foam trays

- Sealed moisture barrier bags