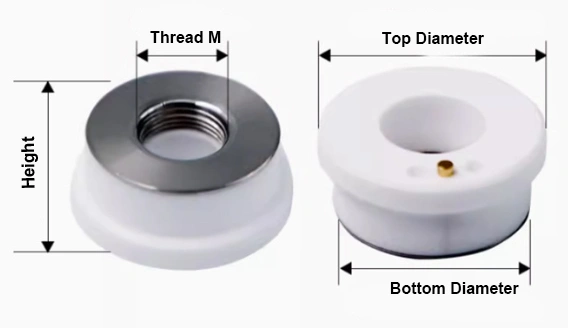

Ceramic ring for a laser cutting machine is a small insulating and positioning component installed between the nozzle and the contact/sensing assembly of the laser cutting head. Its job is to isolate the contact pin electrically, keep the nozzle coaxial with the optical axis, and maintain a consistent sensor gap so the head can trigger correctly during piercing and cutting.

Ceramic Ring for Laser Cutting Machine Benefits

- Low runout interface — nozzle coaxiality supported by concentricity targets (≤0.10 mm).

- Defined thickness stack-up — ring thickness tolerance (±0.05–±0.10 mm) stabilizes sensor gap.

- Material fit for duty — Al₂O₃ for standard use; ZTA option for impact-prone changeovers.

- Thread/model mapping — D28/M11, D32/M14, D41/M11 options reduce compatibility errors.

- Edge integrity — controlled chamfers to lower chip initiation during nozzle swaps.

Ceramic Ring for Laser Cutting Machine Specifications

| Ceramic Ring for Laser Cutting Machine | |||||

| Item NO. | Name | Maximum Outer Dia.(mm) | Lower Outer Dia.(mm) | Height(mm) | M(Thread) |

| AT-D32M14 | Ceramic Rings | 32 | 28 | 12 | M14 |

| AT-D28M11 | Ceramic Rings | 28 | 24.5 | 12 | M11 |

| AT-D25M10 | Ceramic Rings(OSPR) | 25 | 18 | 19 | M10 |

| AT-D21.5M8 | Ceramic Rings(OSPR-3D) | 21.5 | — | 14 | M8 |

| AT-D24M8 | Ceramic Rings(WSX-Mini) | 24 | 20 | 12 | M8 |

| AT-D17.8M8 | Ceramic Rings(OSPR-3D) | 17.8 | 15 | 12.6 | M8 |

| AT-D19.5M8 | Ceramic Rings(JQ-3D) | 19.5 | 16 | 12.5 | M8 |

| AT-D31M11 | Ceramic Rings(PLST) | 31 | 26 | 13.5 | M11 |

| AT-D28.7M11 | Ceramic Rings(IPG) | 28.7 | 23.3 | 10.5 | M11 |

| AT-D32M12 | Ceramic Rings(TL) | 32 | 28 | 12 | M12 |

| AT-D28M12 | Ceramic Rings(TL) | 28 | 24.5 | 12 | M12 |

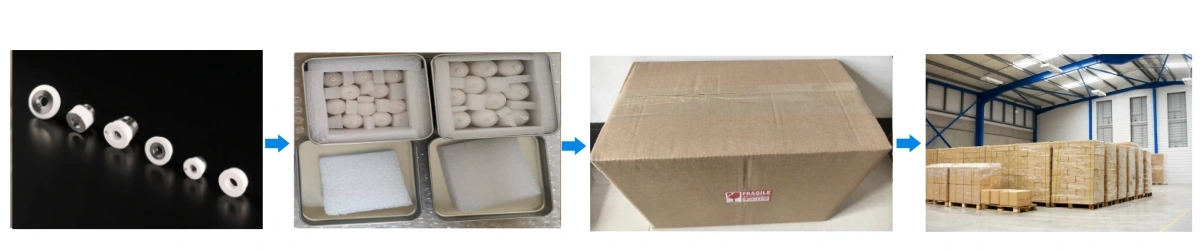

Ceramic Ring for Laser Cutting Machine Packaging

- Each ceramic ring is individually packed in anti-static foam trays.