A High Purity Alumina Ceramic Dome Cover is a ≥99.5% Al₂O₃ chamber lid shaped as a dome and used as the upper wall of plasma etch, PVD and CVD process chambers. It provides a dense, low-contamination barrier that resists plasma and chemicals, helping keep process conditions stable.

High Purity Alumina Ceramic Dome Cover Benefits

-

Geometry matched to your chamber design

Each High Purity Alumina Ceramic Dome Cover is produced according to chamber models or drawings so that bolt circles, seal grooves and reference surfaces align with existing vacuum hardware. -

Controlled wall thickness for process uniformity

Uniform wall thickness and curvature help maintain even plasma density and temperature distribution across the wafer or workpiece area. -

Low contamination alumina microstructure

High purity, low-sodium alumina and controlled sintering conditions reduce mobile ions and loose grains, which supports low particle counts during long coating runs. -

Machined sealing and reference surfaces

Critical sealing faces and alignment shoulders are machined to fine roughness, improving vacuum sealing and repeatable installation. -

Compatible with various chamber chemistries

The High Purity Alumina Ceramic Dome Cover is suitable for halogen-based etch gases and typical PVD/CVD environments when paired with appropriate chamber cleaning regimes.

High Purity Alumina Dome Cover Properties

| Item | Diameter(mm) | Length(mm) | Hore Diameter(μm) | Purity(%) | MOQ (pcs) |

| AT-FT-7001 | 20 | 10 | 0.8 | 98 | 10 |

| AT-FT-7002 | 25 | 15 | 0.8 | 98 | 10 |

| AT-FT-7003 | 36 | 15 | 0.8 | 98 | 10 |

| AT-FT-7004 | 30 | 48 | 0.8 | 98 | 10 |

| AT-FT-7005 | 35 | 10 | 1 | 98 | 10 |

| AT-FT-7006 | 40 | 20 | 0.8 | 98 | 10 |

| AT-FT-7007 | 60 | 35 | 0.8 | 98 | 10 |

| AT-FT-7008 | 80 | 48 | 0.8 | 98 | 10 |

High Purity Alumina Dome Cover Specifications

| High Purity Alumina Dome Cover | ||

| Item No. | Diameter (mm) | Thickness (mm) |

| AT-HP-Q01 | Customize | |

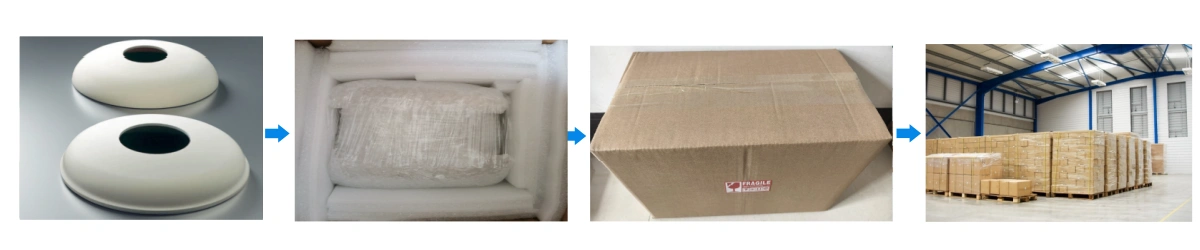

High Purity Alumina Dome Cover Packaging

- Each High Purity Alumina Ceramic Dome Cover is wrapped in clean soft film or foam sheet to protect the functional surfaces.

- The dome is fixed in a shaped foam or molded support inside a double corrugated carton or wooden crate to avoid shock during transport.