A High Purity Alumina Ceramic Grinding Disc is a flat disc made from high-purity alumina (typically ≥99.7–99.8% Al₂O₃) used as a working surface or carrier in flat grinding, lapping, and polishing processes. It provides a hard, wear-resistant, dimensionally stable interface that helps control flatness, thickness, and surface finish of the parts being processed.

High Purity Alumina Ceramic Grinding Disc Benefits

-

Flatness-grade options

Multiple flatness grades can be specified so the High Purity Alumina Ceramic Grinding Disc matches the contact uniformity your lapping or polishing recipe requires, helping control removal rate variation and reduce process drift over long runs. -

Low-wear working face

The alumina grinding surface maintains hardness and abrasion resistance in contact with slurry and abrasive media, extending the interval between resurfacing or replacement and keeping geometry changes predictable instead of sudden. -

Stable thickness profile

A controlled thickness and parallelism window helps keep pressure distribution and machine gap settings consistent across discs, which supports repeatable stock-removal behavior and reduces time spent on re-tuning fixtures. -

Edge integrity control (chamfer/radius options)

Edges can be supplied with defined chamfers or radii and chip-limit criteria, lowering the risk of edge chipping during handling and mounting and reducing the chance of loose fragments marking sensitive parts. -

Feature-ready geometry

The High Purity Alumina Ceramic Grinding Disc can integrate holes, slots, grooves, pockets, or step features to align with your existing carrier, slurry flow pattern, vacuum/hold-down layout, or mounting pattern, so new discs drop into current tooling without redesign.

High Purity Alumina Ceramic Grinding Disc Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

High Purity Alumina Grinding Disc Specification

| High Purity Alumina Grinding Disc | ||

| Item No. | Diameter (mm) | Thickness (mm) |

| AT-HP-YMB01 | Customize | |

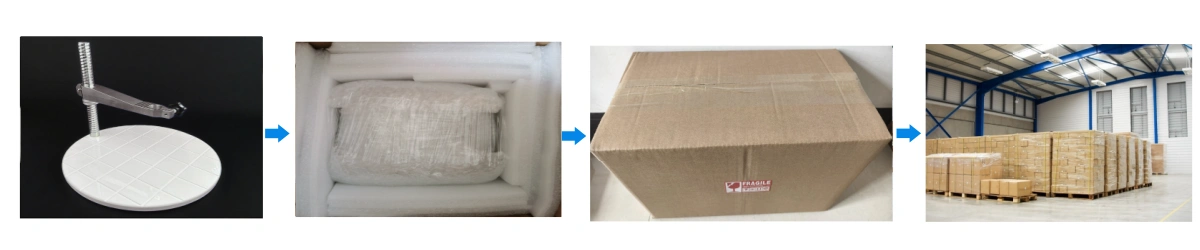

High Purity Alumina Grinding Disc Packaging

- Individual protection: each alumina disc is separated to avoid face-to-face contact marks.

- Edge protection: foam ring/corner protection reduces edge chipping in transit.