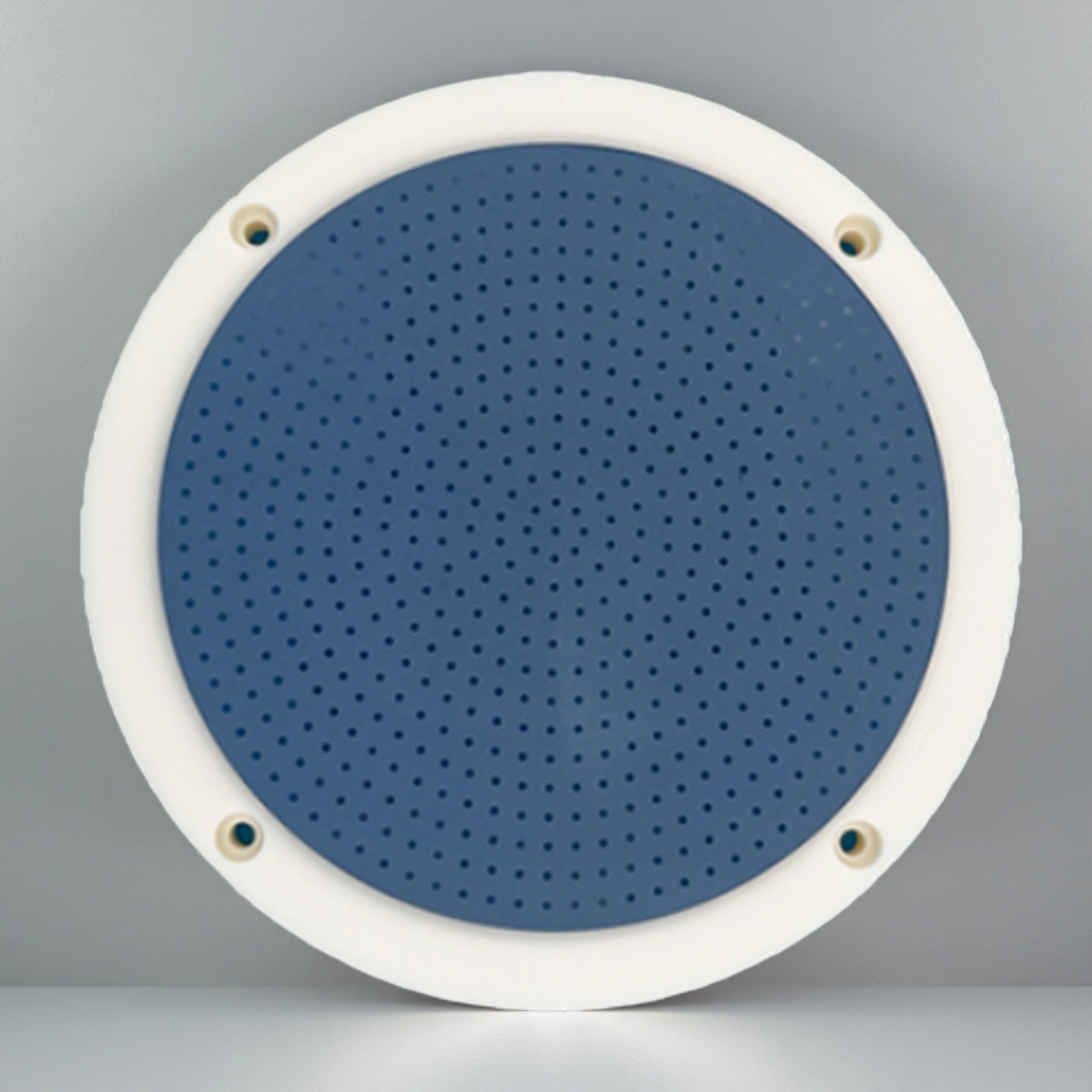

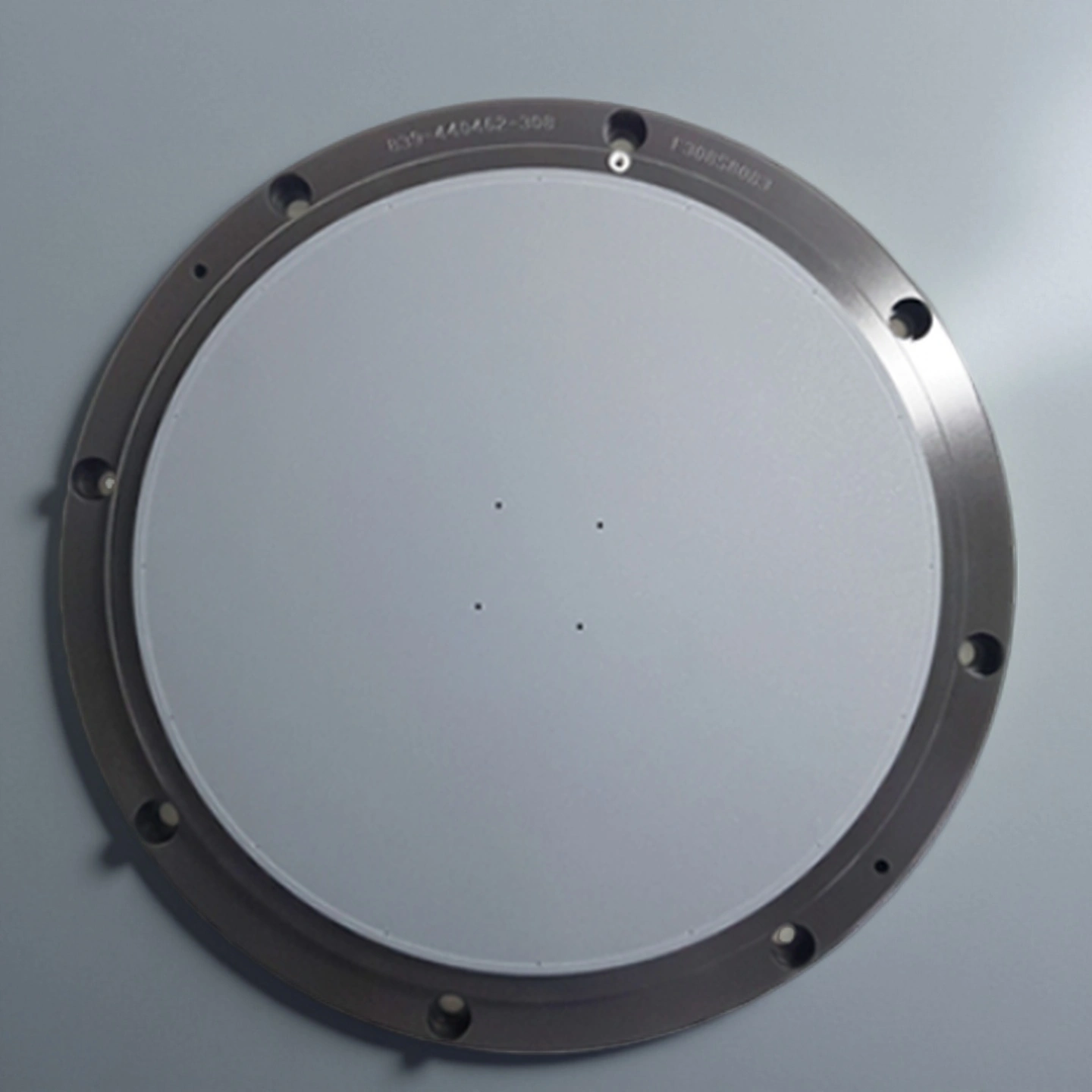

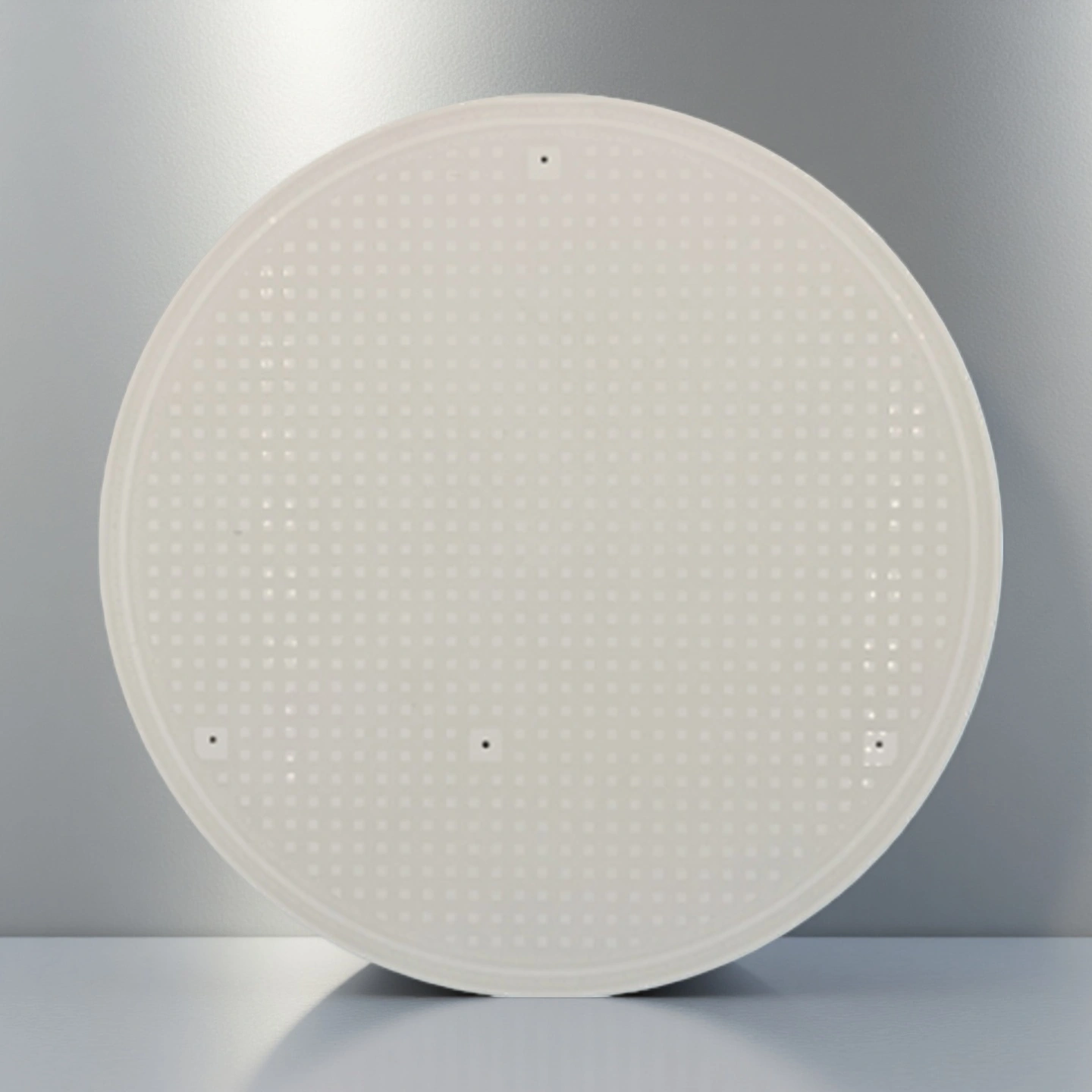

A high purity alumina electrostatic chuck is a ceramic clamping plate that uses electrostatic force to hold wafers, glass panels or other flat substrates in place during vacuum, plasma or thermal processing. It is made from high-purity Al₂O₃ as the dielectric body with embedded electrodes and, when a voltage is applied, it generates a controlled electrostatic attraction that stabilises the substrate, supports uniform temperature control and reduces mechanical contact points that can.

High Purity Alumina Electrostatic Chuck Benefits

-

Process-matched electrode layout – Electrode pattern, polarity and clamping area are adapted to the customer’s chamber geometry and process pressure range, improving chucking uniformity and release behaviour.

-

Controlled gas distribution – Backside grooves and gas holes are machined in the alumina body to support helium or process gas distribution, with edge design attention around holes to mitigate local arcing risk.

-

Optimised surface quality – The clamping surface is ground and optionally polished to a specified flatness and roughness, helping to stabilise friction and reduce stiction after plasma or thermal cycles.

-

High purity dielectric body – The alumina composition and firing route are selected for stable resistivity and dielectric strength under repeated thermal cycling, reducing leakage and charging drift.

-

Integration with cooling and mounting features – The chuck can be machined to interface with metallic baseplates, cooling channels and lift-pin modules, simplifying integration into existing vacuum chambers.

High Purity Alumina Electrostatic Chuck Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

High Purity Alumina Electrostatic Chuck Specifications

| High Purity Alumina Electrostatic Chuck | ||

| Item No. | Diameter (mm) | Thickness (mm) |

| AT-HP-JDP01 | Customize | |

High Purity Alumina Electrostatic Chuck Packaging

- Each high purity alumina electrostatic chuck is first wrapped with clean, non-abrasive protective film to shield the clamping surface from scratches.

- Cushioning foam or tailored foam inserts surround the ceramic in a rigid inner carton, limiting movement during transport.