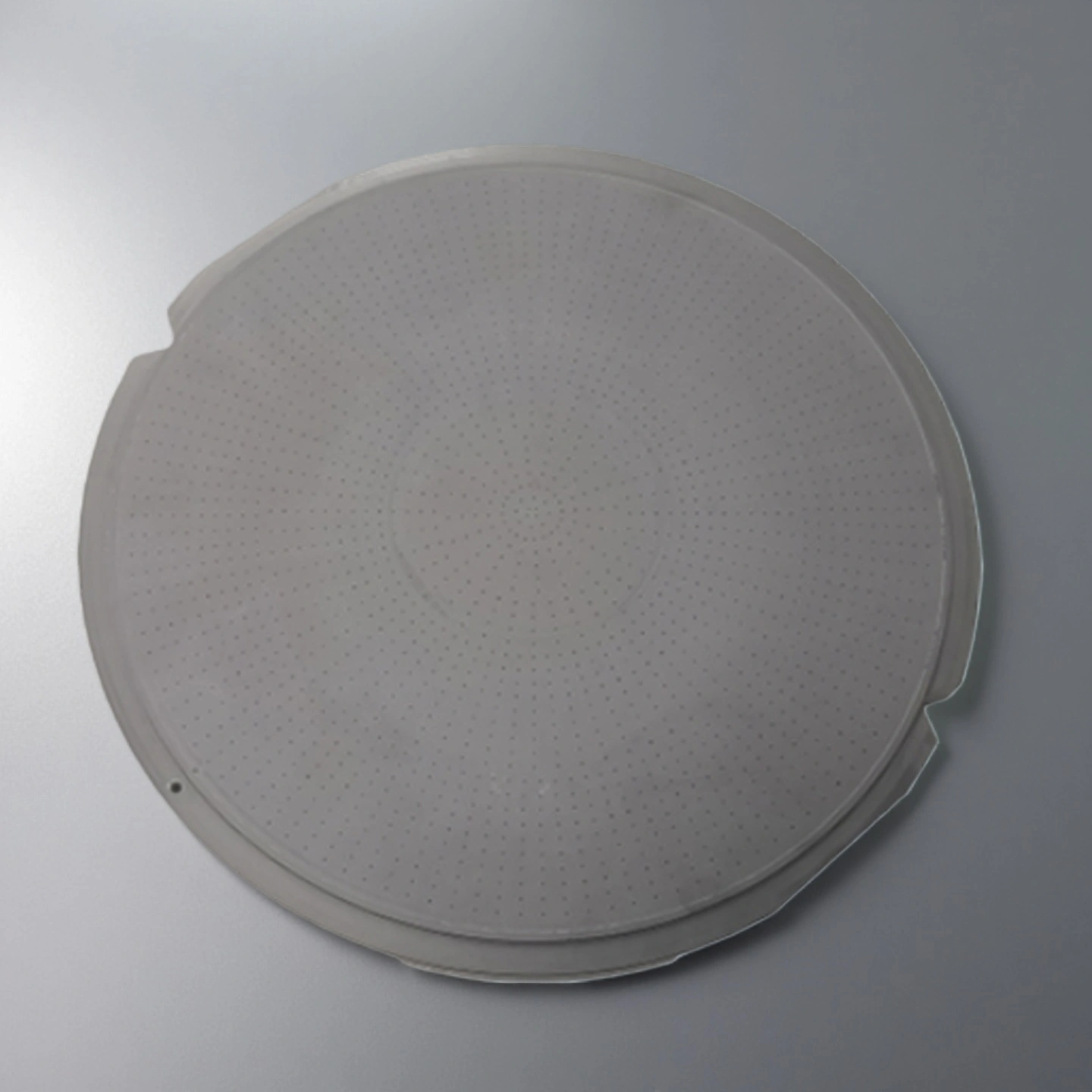

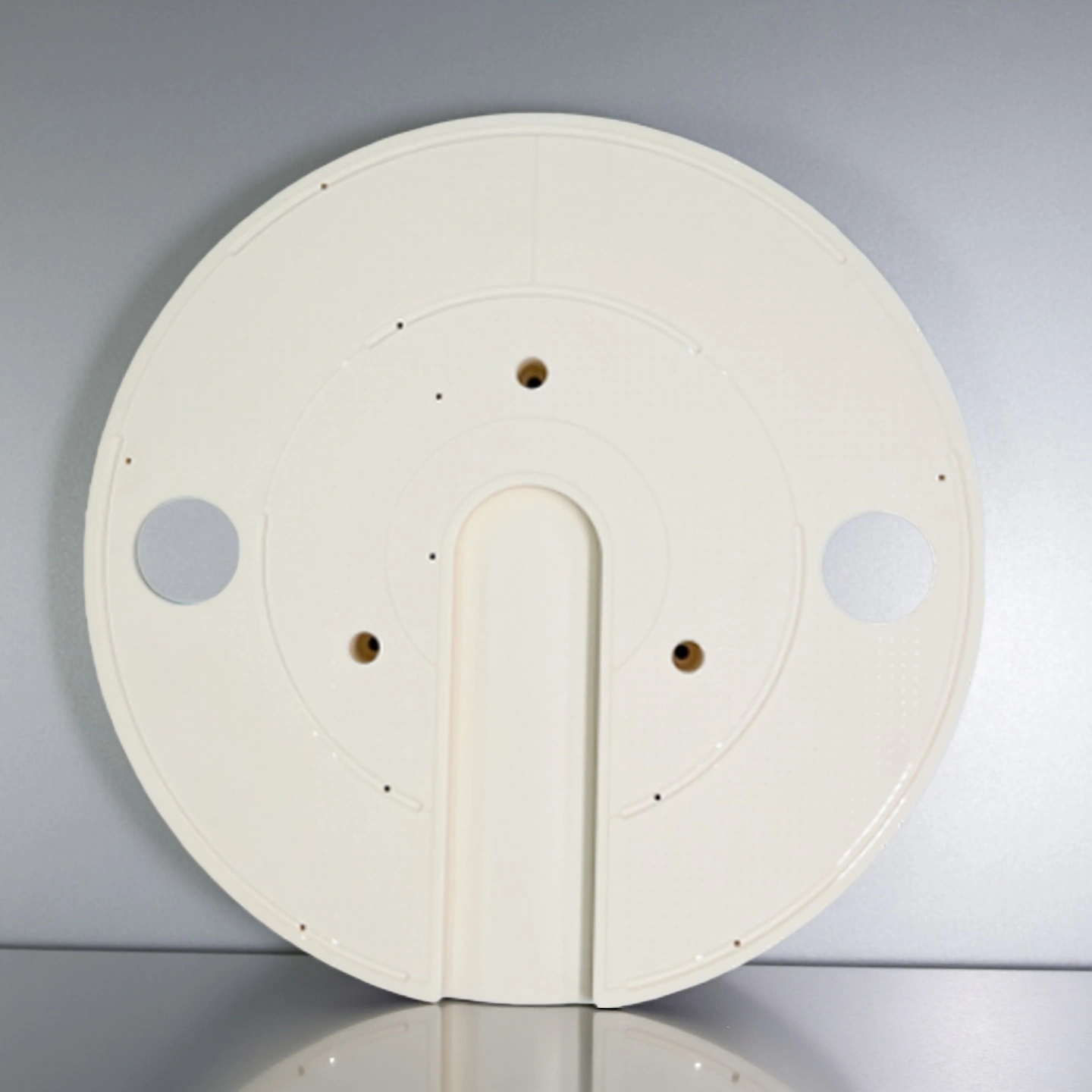

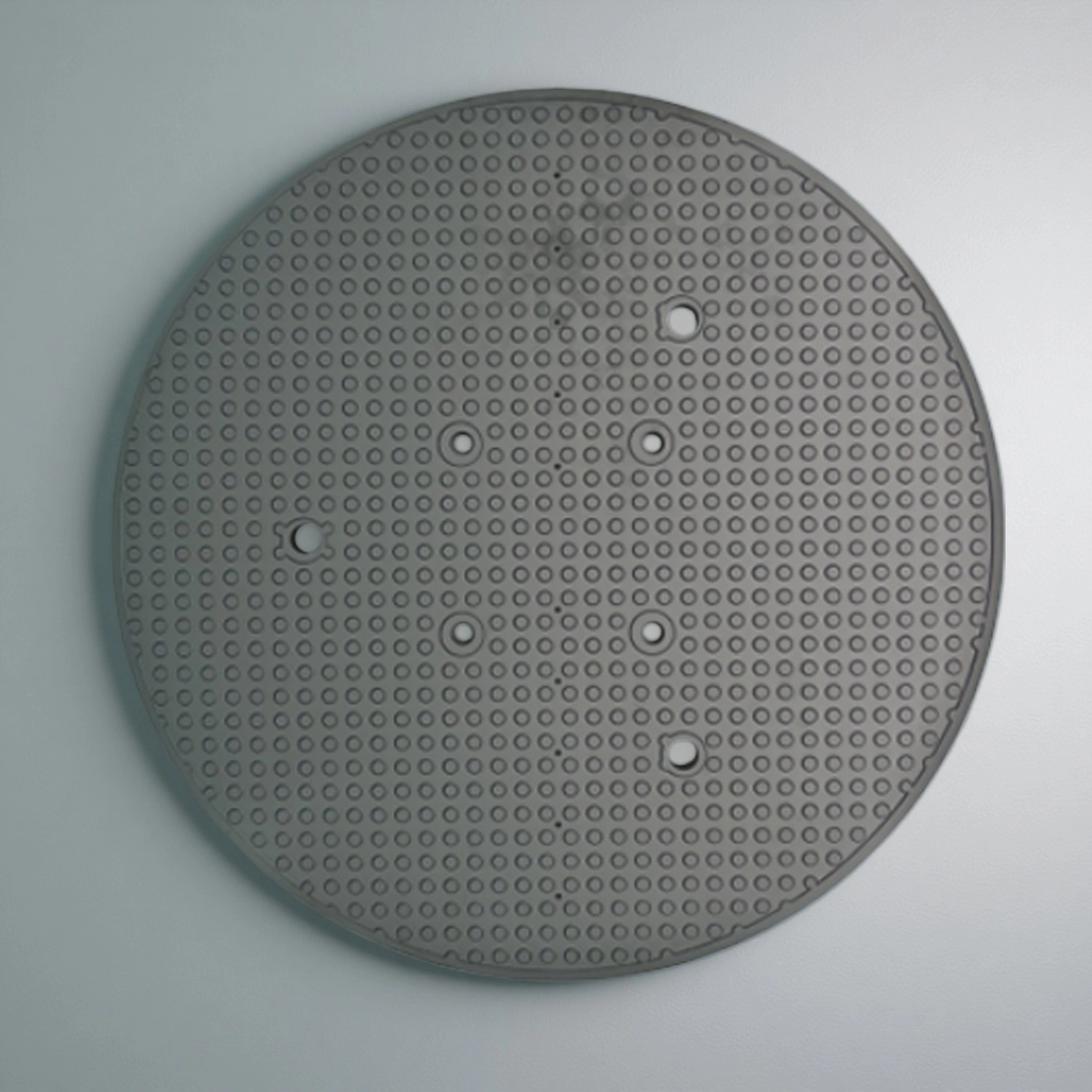

A High Purity Alumina Vacuum Chuck is a porous ceramic workholding plate made from high-purity Al₂O₃ that uses vacuum to clamp wafers, glass panels or other flat parts uniformly on its surface. Vacuum is drawn through a network of micron-scale pores and internal channels in the alumina body, keeping thin and fragile workpieces flat and stable during grinding, thinning, polishing, dicing or inspection while maintaining good cleanliness and dimensional stability.

High Purity Alumina Vacuum Chuck Benefits

-

Uniform clamping of ultrathin workpieces – the porous alumina surface draws vacuum through thousands of fine pores, distributing the holding force over the entire contact area instead of a few grooves. This helps keep wafers below 100 μm thickness or fragile glass panels flat during grinding, thinning or dicing, reducing local bending, print-through marks and sudden slip when the tool accelerates or decelerates.

-

High flatness for precision grinding and metrology – after precision grinding and lapping, a high purity alumina vacuum chuck can reach flatness on the order of a few microns over a 200–300 mm clamping area. This gives the workpiece a stable reference plane, supports tight SFQR and total-thickness-variation control, and reduces chuck-induced errors in optical or 3D measurement systems.

-

Stable material for cleanroom use – high purity alumina has low outgassing and good resistance to common cleaning agents and process chemicals, so the vacuum chuck introduces fewer mobile ions and particles into the process chamber. The hard ceramic surface also resists wear from repeated wafer loading, which helps maintain cleanliness and dimensional stability over long tool lifetimes.

-

Microporous surface adaptable to many part sizes – controlled pore size and porosity let one high purity alumina vacuum chuck hold full wafers, partial wafers or multiple small components without redesigning the fixture. By tuning pore characteristics and vacuum zoning, the same chuck can be used for different product families while keeping leakage within the pump capacity and maintaining consistent holding force.

-

Serviceable workholding platform – unlike soft vacuum cups or thin carrier plates that are replaced frequently, porous ceramic vacuum chucks can be re-lapped when the surface wears or flatness drifts. This allows users to restore performance, extend service life across many maintenance cycles and lower the long-term fixture cost per processed wafer or part.

High Purity Alumina Vacuum Chuck Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

High Purity Alumina Vacuum Chuck Specification

| High purity alumina vacuum chuck | ||

| Item No. | Diameter (mm) | Thickness (mm) |

| AT-HP-XP01 | Customize | |

High Purity Alumina Ceramic Vacuum Chuck Packaging

- Each high purity alumina vacuum chuck is cleaned, dried and covered with a cleanroom-grade protective film on the porous surface.

- The chuck is locked in a custom foam cradle or molded tray to prevent edge damage and bending during transport.