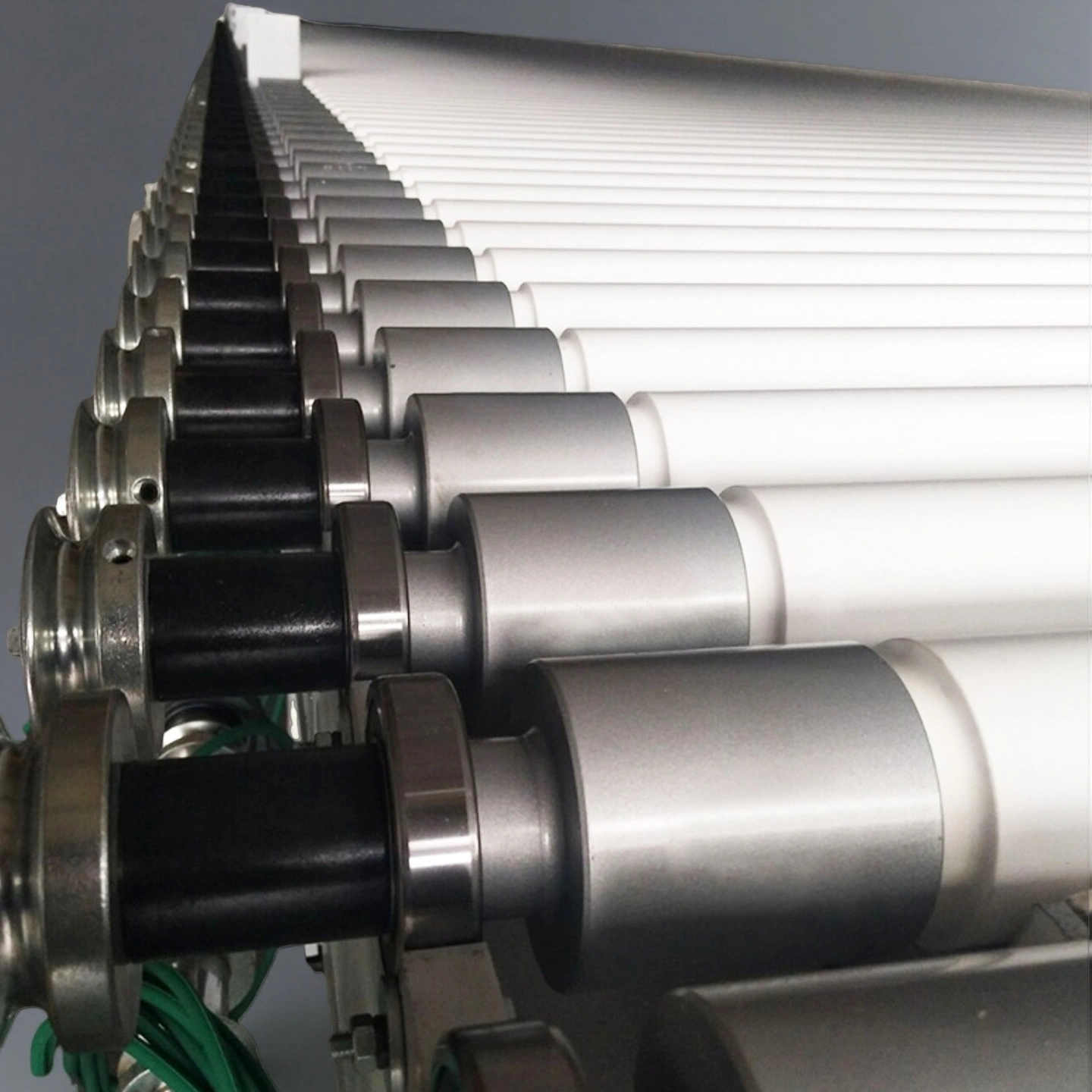

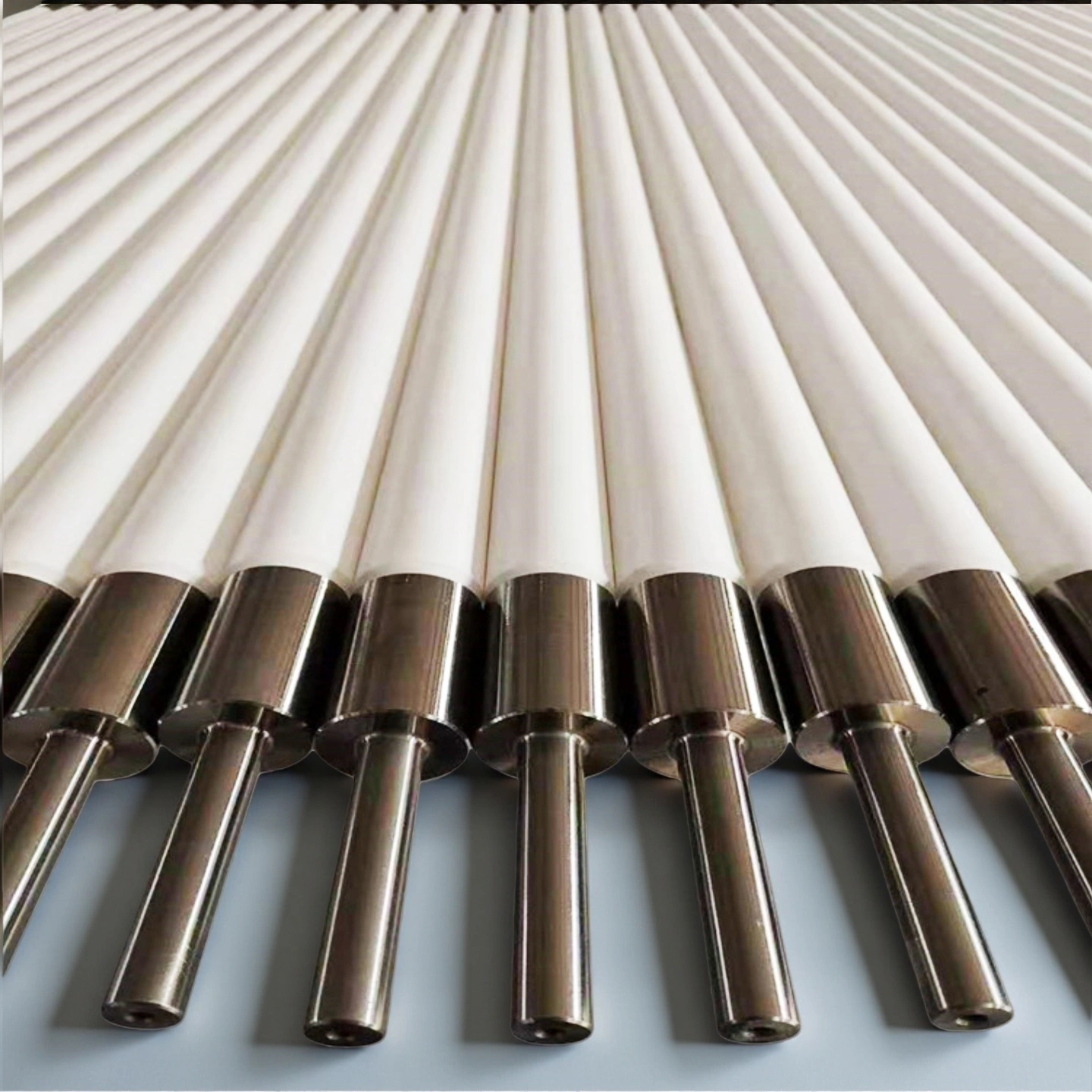

Quartz ceramic rollers are fused-silica–based roller components used to transport products through high-temperature zones in glass tempering furnaces, solar cell firing lines and industrial roller kilns. They combine low thermal expansion, thermal shock resistance and stable dimensional behaviour at elevated temperatures, allowing continuous conveying without distortion or excessive run-out.

Quartz Ceramic Rollers Benefits

-

Low run-out and straightness control

– Total indicated run-out and straightness can be controlled within a few tenths of a millimetre over multi-meter lengths, supporting stable tracking of glass sheets and ceramic products. -

Low thermal expansion and high temperature stability

– Fused silica quartz ceramic rollers maintain dimensional stability at 1000–1100°C with a typical CTE around 0.5×10⁻⁶/K, reducing thermal distortion and misalignment in roller hearth systems. -

Thermal shock resistance in cyclic furnace operation

– Quartz ceramic rollers tolerate repeated heating and cooling cycles in production furnaces, reducing breakage during start-up, maintenance and process changes. -

Clean surface and low contamination to products

– High purity quartz ceramic material and controlled surface finish help minimise particle shedding, surface marks and contamination on glass, wafers and ceramic products. -

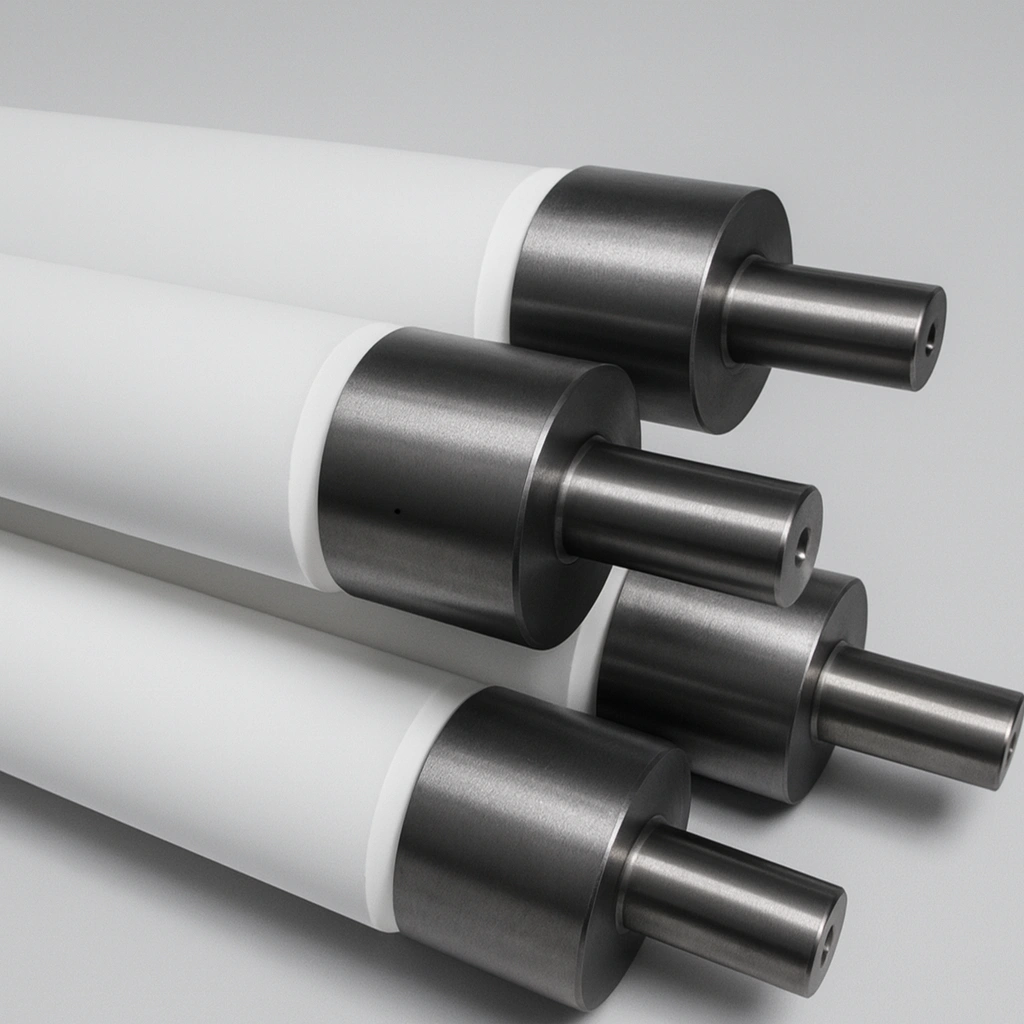

Adaptable end designs for various drive systems

– Ends can be machined for keyed connections, tapered seating, metal end caps or bearing interfaces, making quartz ceramic rollers compatible with existing drive and support systems.

Quartz Ceramic Rollers Properties

| Item | Value | |

| Chemical Composition | SiO2(Wt) | ≥99.8% |

| Al2O3 | ≤0.12% | |

| Fe2O3 | ≤0.02% | |

| TiO2 | ≤0.018% | |

| MgO | ≤0.004% | |

| Na2O | ≤0.004% | |

| CaO | ≤0.007% | |

| K2O | ≤0.004% | |

| Physical Properties | Bulk Density | ≥1.90-1.95g/cm3 |

| Apparent Porosity | ≤15% | |

| Apparent Porosity | ≥50MPa | |

| Flexural Strength (Room Temperature) | ≥25MPa | |

| Flexural Strength (High Temperature) | ≥28MPa | |

| Crystal Phase Content | <1% | |

| Thermal Shock Resistance (1100°C → water quench) | ≥10 | |

| Thermal Properties | Thermal Conductivity @ 20°C | 20℃:0.64W/m°K |

| 500℃:0.81W/m°K | ||

| 1090℃:0.88W/m°K | ||

| Thermal Expansion Coefficient (20–1100°C) | ≤0.9×106 | |

| Thermal Expansion Coefficient (20–1100°C) | 1650 |

Quartz Ceramic Rollers Specifications

| Item | Diameter(mm) | Length(mm) | Purity of Sio2(%) |

| AT-SYT-G1001 | 15 | 600 | 99.8 |

| AT-SYT-G1002 | 20 | 800 | 99.8 |

| AT-SYT-G1003 | 25 | 1000 | 99.8 |

| AT-SYT-G1004 | 30 | 1200 | 99.8 |

| AT-SYT-G1005 | 35 | 1250 | 99.8 |

| AT-SYT-G1006 | 40 | 1600 | 99.8 |

| AT-SYT-G1007 | 45 | 1800 | 99.8 |

| AT-SYT-G1008 | 50 | 2000 | 99.8 |

| AT-SYT-G1009 | 55 | 2280 | 99.8 |

| AT-SYT-G1010 | 60 | 2571 | 99.8 |

| AT-SYT-G1011 | 35 | 1230 | 99.8 |

| AT-SYT-G1012 | 70 | 2714 | 99.8 |

| AT-SYT-G1013 | 75 | 2987 | 99.8 |

| AT-SYT-G1014 | 85 | 3360 | 99.8 |

| AT-SYT-G1015 | 95 | 3805 | 99.8 |

| AT-SYT-G1016 | 20-31 | 1600-3100 | 99.8 |

| AT-SYT-G1017 | 32 | 1800-3100 | 99.8 |

| AT-SYT-G1018 | 33.7 | 1800-3100 | 99.8 |

| AT-SYT-G1019 | 35 | 2000-3200 | 99.8 |

| AT-SYT-G1020 | 36 | 2000-3300 | 99.8 |

| AT-SYT-G1021 | 40 | 2000-3500 | 99.8 |

| AT-SYT-G1022 | 42 | 2200-3800 | 99.8 |

| AT-SYT-G1023 | 45 | 2200-3800 | 99.8 |

| AT-SYT-G1024 | 50 | 2400-4600 | 99.8 |

| AT-SYT-G1025 | 55 | 2700-5000 | 99.8 |

| AT-SYT-G1026 | 60 | 2700-5000 | 99.8 |

| AT-SYT-G1027 | 65-120 | 3000-5000 | 99.8 |

| AT-SYT-G1028 | 150 | 1800-2600 | 99.8 |

| AT-SYT-G1029 | 180 | 1800-2600 | 99.8 |

| AT-SYT-G1030 | 300 | 2000-3800 | 99.8 |

Fused Quartz Ceramic Roller Packaging

- Each quartz ceramic roller is wrapped in soft protective film or foam sleeves along the full length to prevent surface abrasion.