ADCERAX® Silicon Carbide Burner Nozzle is designed for high-temperature combustion environments where flame stability, thermal efficiency, and long-cycle reliability determine overall furnace performance. Its SiSiC/RBSiC microstructure supports consistent heat transfer and resistance to oxidation, allowing stable firing behavior even under rapid temperature swings and variable fuel-air conditions. This combination of thermal conductivity, structural endurance, and atmosphere tolerance makes it suitable for industrial kilns and reheating systems seeking improved uniformity, reduced energy consumption, and extended maintenance intervals.

High-Performance Features for Demanding Industrial Combustion

-

Thermal Stability at 1600°C

The nozzle performs reliably in continuous firing zones where peak gas temperatures reach up to 1600°C, maintaining structural integrity without deformation. This temperature margin allows stable operation during long heating cycles typical of tunnel kilns and roller kilns.

-

Fast Heat Transfer into Furnace Atmosphere

With conductivity reaching up to 160 W/m·K, the nozzle transfers heat faster than alumina components (<10 W/m·K), reducing burner response time. This improvement supports tighter control of firing curves and faster temperature recovery.

-

Accurate Flow Channel Configuration

Internal channels maintain cross-sectional integrity even under high-velocity gas flows reaching 50–90 m/s, supporting uniform mixing and stable jet formation. This helps prevent flame pulsation in premix systems.

Technical Specifications of Silicon Carbide Burner Nozzle

ADCERAX® Silicon Carbide Burner Nozzle is engineered with a high-strength SiSiC/RBSiC material system that delivers reliable performance under sustained high-temperature combustion, rapid thermal cycling, and chemically aggressive furnace atmospheres. Its microstructural uniformity, thermal conductivity, oxidation stability, and mechanical endurance support consistent operation in industrial kilns and high-efficiency combustion systems.

| Property |

Specification |

| Material System |

SiSiC / RBSiC |

| SiC Content |

> 90% |

| Bulk Density |

2.95–3.05 g/cm³ |

| Open Porosity |

< 1% |

| Flexural Strength (RT) |

> 100 MPa |

| Compressive Strength |

> 900 MPa |

| Thermal Conductivity |

120–160 W/m·K |

| Maximum Use Temperature |

1350–1600°C |

| Thermal Shock Resistance |

800–1000°C quench stability |

| Oxidation Resistance |

Stable above 1300°C |

| Creep Resistance |

Low deformation under >1400°C soak |

| Chemical Resistance |

Acid/alkali/chloride/sulfur tolerant |

| Young’s Modulus |

≈ 320–340 GPa |

| Hardness |

≈ 22–25 GPa |

Dimensions of Silicon Carbide Burner Nozzle

|

Item |

Inner Diameter(mm) |

Outer Diameter(mm) |

Length(mm) |

|

AT-THG-P1001 |

30 |

50 |

100-2000 |

|

AT-THG-P1002 |

35 |

55 |

100-2000 |

|

AT-THG-P1003 |

40 |

65 |

100-2000 |

|

AT-THG-P1004 |

45 |

70 |

100-2000 |

|

AT-THG-P1005 |

50 |

70 |

100-2000 |

|

AT-THG-P1006 |

55 |

75 |

100-2000 |

|

AT-THG-P1007 |

60 |

78 |

100-2000 |

|

AT-THG-P1008 |

65 |

80 |

100-2000 |

|

AT-THG-P1009 |

70 |

80 |

100-2000 |

|

AT-THG-P1010 |

80 |

105 |

100-2000 |

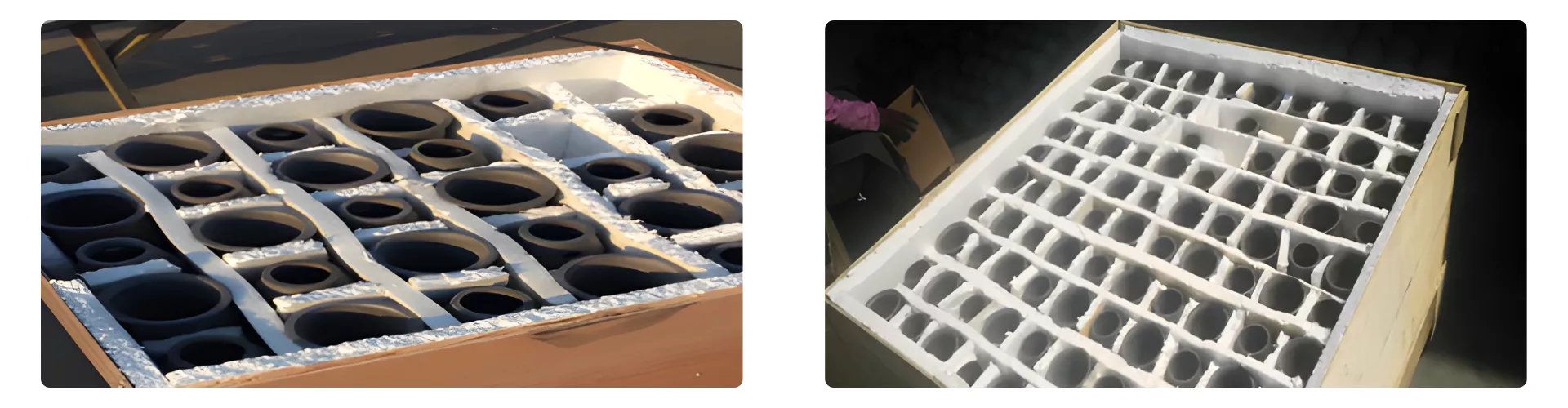

Packaging Process for Silicon Carbide Burner Nozzle

Silicon Carbide Burner Nozzle is packed in reinforced wooden crates with custom-cut foam cells that immobilize each nozzle during long-distance transport. The compartmentalized layout prevents surface abrasion and impact concentration, keeping the SiSiC/RBSiC components stable under vibration. Every crate is sealed with moisture-controlled insulation to ensure the nozzles arrive in pristine condition for immediate installation.

ADCERAX® Silicon Carbide Burner Nozzle Resolves Critical Combustion Challenges in Modern Industrial Heating Systems

ADCERAX® Silicon Carbide Burner Nozzle used in advanced industrial kilns, reheating furnaces, and high-temperature oxidation systems is required to stabilize flame geometry, withstand rapid thermal fluctuations, and deliver predictable heat transfer under chemically aggressive atmospheres.

-

Silicon Carbide Burner Nozzle in Roller Hearth Kilns

✅Key Advantages

1. Controlled Lateral Temperature Profile

The ADCERAX® Silicon Carbide Burner Nozzle helps cut lateral kiln temperature deviation from typical ±18–25°C down into an optimized band of about ±8–12°C. This tighter profile reduces differential shrinkage and densification scatter across electronic ceramic layers.

2. Stable Flame Geometry over Long Campaigns

High thermal conductivity in the range of 120–160 W/m·K supports consistent jet penetration even after 200–300 hours of continuous firing. Flame shape remains stable as the kiln cycles through load changes, reducing the need for frequent curve retuning.

3. Reduced Hot/Cold Zone Formation

Microstructural stability at 1350–1500°C limits local loss of conductivity that usually leads to hot or cold spots near burner ports. As a result, the kiln maintains more uniform conditions along the roller path and improves dimensional stability of the fired components.

✅ ️Problem Solved

An electronic ceramics producer operating a roller hearth kiln experienced lateral temperature deviations of around ±20°C, which led to warpage and density variation across multilayer parts. Frequent firing-curve corrections were required to keep yields acceptable, increasing energy use and engineering workload. After implementing ADCERAX® Silicon Carbide Burner Nozzle with optimized outlet geometry, cross-kiln deviation was reduced into the ±8–10°C range under the same production rate. The kiln ran longer without curve interventions, and the proportion of batches requiring rework decreased noticeably as shrinkage behavior became more consistent.

-

Silicon Carbide Burner Nozzle in Steel Reheating Furnaces

✅Key Advantages

1. Extended Throat Life in Scale-Laden Flow

With compressive strength above 900 MPa, the ADCERAX® Silicon Carbide Burner Nozzle resists erosion from scale and high-velocity combustion gases. Campaigns that previously required nozzle inspection every 3–6 months can be extended to significantly longer intervals under comparable firing schedules.

2. Stable Burner Alignment and Impingement

High stiffness in the 320–340 GPa Young’s modulus range keeps burner throats from deforming as furnace walls expand and contract. Flame impingement angle on billets and slabs stays within a narrow deviation band, supporting more even reheating across the load.

3. Improved Thermal Balance Across the Furnace Zone

By maintaining outlet geometry at 1250–1450°C operating temperatures, the nozzle supports more uniform gas distribution across the furnace section. Temperature variation along the steel length and width can be reduced by 10–15°C, helping stabilize downstream rolling forces.

✅ ️Problem Solved

A long-product mill running a pusher-type reheating furnace found that refractory nozzles eroded unevenly under scale-laden flows, causing burner misalignment and non-uniform steel temperature. Variations in reheating led to fluctuating rolling loads and frequent fine-tuning of furnace setpoints. After switching to ADCERAX® Silicon Carbide Burner Nozzle, throat wear over a similar operating period was markedly lower, and burner orientation remained within the intended design envelope. Furnace temperature maps showed a reduction of cross-section deviation by approximately 10–15°C, and the frequency of corrective burner adjustments decreased over subsequent campaigns.

-

Silicon Carbide Burner Nozzle in Tunnel Kilns

✅Key Advantages

1. Longitudinal Temperature Stability

The nozzle supports high thermal conductivity that stabilizes heat transfer along the tunnel axis, ensuring more repeatable firing conditions. This stability reduces the development of hot–cold bands that typically impair ceramic dimensional accuracy.

2. Sustained Geometry Integrity

The SiC microstructure retains throat geometry under 1350–1500°C tunnel kiln operation, preventing flame distortion caused by progressive oxidation. This integrity maintains a predictable flame profile across long campaigns.

3. Reduced Atmosphere-Induced Degradation

Low <1% open porosity limits chemical ingress from kiln atmospheres containing alkali volatilization or mineral dust. As a result, the nozzle maintains smooth internal surfaces that support clean combustion and controlled jet momentum.

✅ ️Problem Solved

A European ceramic manufacturer operating a high-throughput tunnel kiln reported recurrent longitudinal temperature drift attributed to flame asymmetry and geometry degradation of conventional burner nozzles. This issue caused variation in product shrinkage and required frequent adjustments to the primary and secondary air circuits. After installing ADCERAX® Silicon Carbide Burner Nozzle with optimized outlet shaping and oxidation-resistant SiC composition, longitudinal ΔT fluctuations decreased noticeably along the continuous firing path. The kiln maintained stable combustion behavior over long operating intervals without additional fuel compensation. Yield consistency improved as firing deviation narrowed and curve recalibration frequency dropped.

ADCERAX® Silicon Carbide Burner Nozzle User Guide for Safe, Stable, and Efficient Furnace Operation

The Silicon Carbide Burner Nozzle requires proper installation, commissioning, and maintenance control to ensure stable combustion behavior, predictable flame geometry, and long service life under high-temperature and variable-atmosphere conditions.

-

Installation Preparations and Mounting Requirements

1. Alignment Verification

Installing engineers should confirm that burner ports and furnace walls maintain stable axial alignment before mounting the nozzle. Misalignment increases stress concentration and leads to premature geometry drift during thermal expansion cycles. Correct anchor positioning ensures consistent jet penetration and predictable flame shape.

2. Interface Cleanliness Control

All mounting surfaces must be free from scale, dust, and unburnt residue to avoid micro-gaps that cause vibration during firing. Clean interfaces minimize local turbulence and support uniform heat release at burner outlets. Proper preparation also protects the microstructure from point-impact load during initial firing.

3. Progressive Tightening Sequence

Fastening components should be tightened using a gradual cross-pattern to maintain balanced mechanical load on the nozzle. Sudden one-side loading may create localized bending moments that affect long-term dimensional stability. A controlled tightening sequence improves sealing and ensures reliable early-cycle combustion.

-

Operating Conditions and Flame Tuning Recommendations

1. Stable Fuel–Air Ratio Management

Operators should maintain a consistent air-fuel ratio during firing curve transitions to reduce flame oscillation. Abrupt ratio shifts increase thermal shock load on the nozzle and disturb flame anchoring. Controlled adjustments help sustain uniform firing behavior across the combustion zone.

2. Gradual Temperature Ramp-Up

Furnaces should be brought to operating temperature through a progressive ramp to protect the SiC microstructure from unnecessary stress. Rapid spikes introduce steep temperature gradients that challenge thermal shock resistance. Smooth ramping stabilizes jet momentum and improves early-cycle uniformity.

3. Monitoring for Flame Drift

During prolonged runs, operators should periodically observe flame axis symmetry to identify drift caused by local turbulence or upstream pressure changes. Early correction prevents temperature imbalance in the firing zone. Consistent monitoring maintains stable geometry for long-cycle production.

-

Maintenance Intervals and Inspection Procedures

1. Regular Visual Surface Checks

Inspections should document surface condition, looking for abrasion marks, glaze formation, or early pitting caused by fuel impurities. Identifying light wear early prevents downstream disturbances in combustion pattern. Scheduled checks reduce unexpected downtime and maintain thermal uniformity.

2. Port Obstruction Assessment

High-dust or scale-forming environments require periodic verification that burner ports remain free from particulate blockage. Even partial obstruction creates asymmetric jet penetration and temperature deviation within the furnace. Routine cleaning preserves consistent heat transfer and predictable firing behavior.

3. Cycle-Based Replacement Planning

For facilities with high-thermal-load profiles, it is recommended to plan nozzle replacement based on operating hours and combustion intensity, not only visible wear. Proactive scheduling prevents sudden flame instability during high-output production. Predictive maintenance increases furnace uptime and operational reliability.

-

Handling, Storage, and Transportation Precautions

1. Shock-Free Handling Requirements

SiC components must be moved using stable lifting support to prevent point-load impacts. Improper handling can introduce micro-cracks that propagate under high-temperature cycling. Controlled movement ensures the nozzle retains its structural integrity through multiple firing campaigns.

2. Moisture-Controlled Storage

Nozzles should be stored in a dry, temperature-stable environment to avoid moisture condensation on the microstructure. Although the material is oxidation-resistant, moisture contact increases handling risks during ignition cycles. Controlled storage conditions protect long-cycle performance stability.

3. Protective Packaging Retention

Units should remain in foam-cell protective packaging until actual installation to avoid unintended contact damage. The packaging is designed to immobilize each nozzle and prevent edge impacts. Keeping the nozzle protected reduces installation-phase defects and ensures consistent commissioning results.

![]()