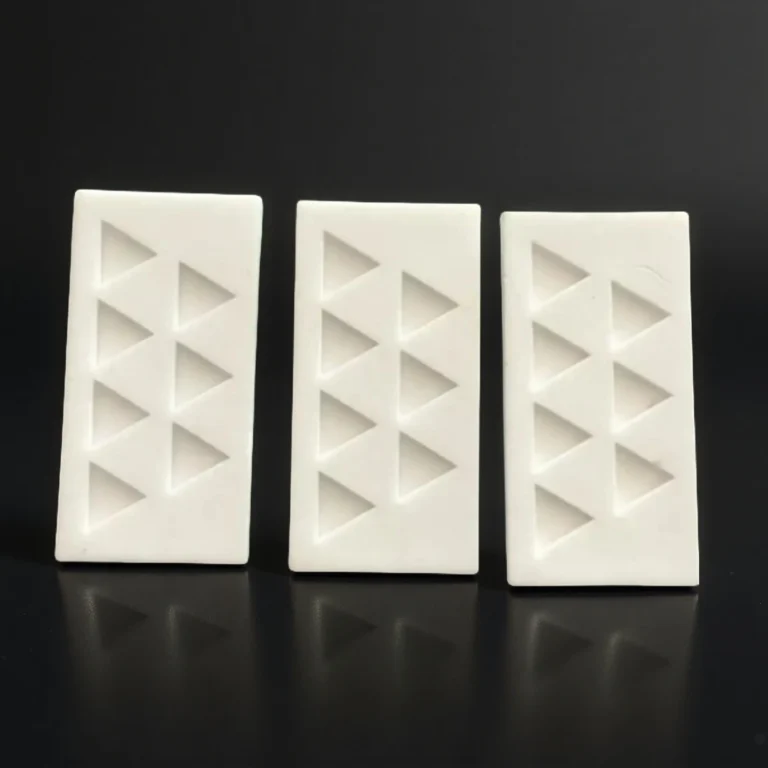

Silicon carbide ceramic trays are high-performance products primarily used in industries where high temperatures and thermal conductivity are required. Made from a combination of silicon and carbon materials, these trays provide exceptional resistance to oxidation and chemical damage, making them suitable for use in furnaces, kilns, and other high-temperature environments.

Advantages of Silicon Carbide Ceramic Tray

- Dimensional Precision ±0.2mm – Maintains flatness for consistent sintering

- High Working Lifespan – Survives >300 cycles at ≥1500°C in oxidizing atmosphere

- Customized Geometry – Available in open, closed, grooved, or stepped surface styles

- Reduced Defect Risk – Prevents warping and particle shedding within controlled environments

- Engineered Body – Densified and finished to prevent microcracks and edge abrasion

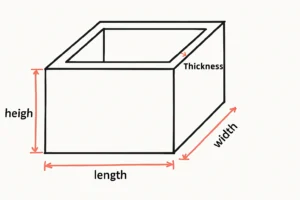

Specifications of SIC Ceramic Tray

Type 1-Rectangular SIC Ceramic Trays

| Item | Length(mm) | Width(mm) | Height(mm) | Thickness(mm) |

| AT-SIC-G1037 | 51.5 | 25.5 | 20.5 | 3.5 |

| AT-SIC-G1038 | 70 | 70 | 25 | 5 |

| AT-SIC-G1039 | 80.5 | 67.5 | 21 | 5 |

| AT-SIC-G1040 | 100 | 100 | 30 | 4 |

| AT-SIC-G1041 | 100 | 30 | 25 | 5 |

| AT-SIC-G1042 | 122 | 49 | 37 | 5 |

| AT-SIC-G1043 | 150 | 150 | 80 | 5.5 |

| AT-SIC-G1044 | 160 | 160 | 72 | 7 |

| AT-SIC-G1045 | 175 | 175 | 50 | 6 |

| AT-SIC-G1046 | 180 | 70 | 35 | 5.5 |

| AT-SIC-G1047 | 190 | 80 | 40 | 6 |

| AT-SIC-G1048 | 200 | 35 | 8 | 5.5 |

| AT-SIC-G1049 | 265 | 175 | 20 | 8 |

| AT-SIC-G1050 | 300 | 300 | 110 | 6 |

| AT-SIC-G1051 | 300 | 300 | 150 | 6.5 |

| AT-SIC-G1052 | 300 | 300 | 175 | 7.5 |

| AT-SIC-G1053 | 320 | 320 | 110 | 6.5 |

| AT-SIC-G1054 | 320 | 320 | 48 | 5.5 |

| AT-SIC-G1055 | 320 | 320 | 60 | 6 |

| AT-SIC-G1056 | 320 | 320 | 75 | 6 |

| AT-SIC-G1057 | 320 | 320 | 80 | 7 |

| AT-SIC-G1058 | 320 | 320 | 85 | 8 |

| AT-SIC-G1059 | 490 | 255 | 50 | 10 |

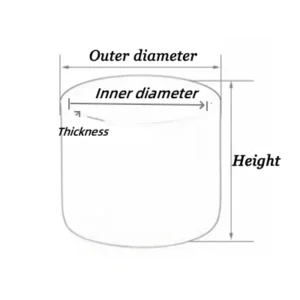

Type 2-Round SIC Ceramic Trays

| Item | Outer Diameter(mm) | Inner Diameter(mm) | Height(mm) | Thickness(mm) |

| AT-SIC-G1001 | 10.0 | 7.8 | 19.0 | 1.1 |

| AT-SIC-G1002 | 12 | 8 | 26 | 2 |

| AT-SIC-G1003 | 14.5 | 10.5 | 33.5 | 2 |

| AT-SIC-G1004 | 20 | 16 | 31 | 2 |

| AT-SIC-G1005 | 22 | 16 | 80 | 3 |

| AT-SIC-G1006 | 23 | 19 | 81 | 2 |

| AT-SIC-G1007 | 28 | 21 | 110 | 3.5 |

| AT-SIC-G1008 | 29 | 22 | 17.5 | 3.5 |

| AT-SIC-G1009 | 29 | 24 | 19.7 | 2.5 |

| AT-SIC-G1010 | 32.5 | 26.5 | 29 | 3 |

| AT-SIC-G1011 | 38 | 29 | 32.5 | 4.5 |

| AT-SIC-G1012 | 38 | 29.8 | 45 | 4.1 |

| AT-SIC-G1013 | 41 | 33 | 71.5 | 4 |

| AT-SIC-G1014 | 42 | 33 | 73 | 4.5 |

| AT-SIC-G1015 | 45 | 38 | 18 | 3.5 |

| AT-SIC-G1016 | 47.5 | 38 | 74 | 4.75 |

| AT-SIC-G1017 | 51 | 41 | 122 | 5 |

| AT-SIC-G1018 | 51 | 44 | 73 | 3.5 |

| AT-SIC-G1019 | 52 | 39 | 144 | 6.5 |

| AT-SIC-G1020 | 53 | 42 | 124 | 5.5 |

| AT-SIC-G1021 | 60 | 51 | 100 | 4.5 |

| AT-SIC-G1022 | 61 | 51 | 102 | 5 |

| AT-SIC-G1023 | 61 | 52 | 102 | 4.5 |

| AT-SIC-G1024 | 61.5 | 53 | 122 | 4.25 |

| AT-SIC-G1025 | 63 | 52 | 103.5 | 5.5 |

| AT-SIC-G1026 | 65 | 55 | 64.5 | 5 |

| AT-SIC-G1027 | 71 | 61 | 111 | 5 |

| AT-SIC-G1028 | 72.5 | 62.5 | 113 | 5 |

| AT-SIC-G1029 | 73 | 62.5 | 125.5 | 5.25 |

| AT-SIC-G1030 | 80 | 58 | 91 | 11 |

| AT-SIC-G1031 | 93 | 83 | 103 | 5 |

| AT-SIC-G1032 | 94 | 83.5 | 104.5 | 5.25 |

| AT-SIC-G1033 | 100 | 92 | 132 | 4 |

| AT-SIC-G1034 | 104 | 90 | 182 | 7 |

| AT-SIC-G1035 | 105 | 95 | 135.5 | 5 |

| AT-SIC-G1036 | 380 | 344 | 255 | 18 |

Packing

Each tray is individually packed using PE foam surfaces and double-corrugated cartons.