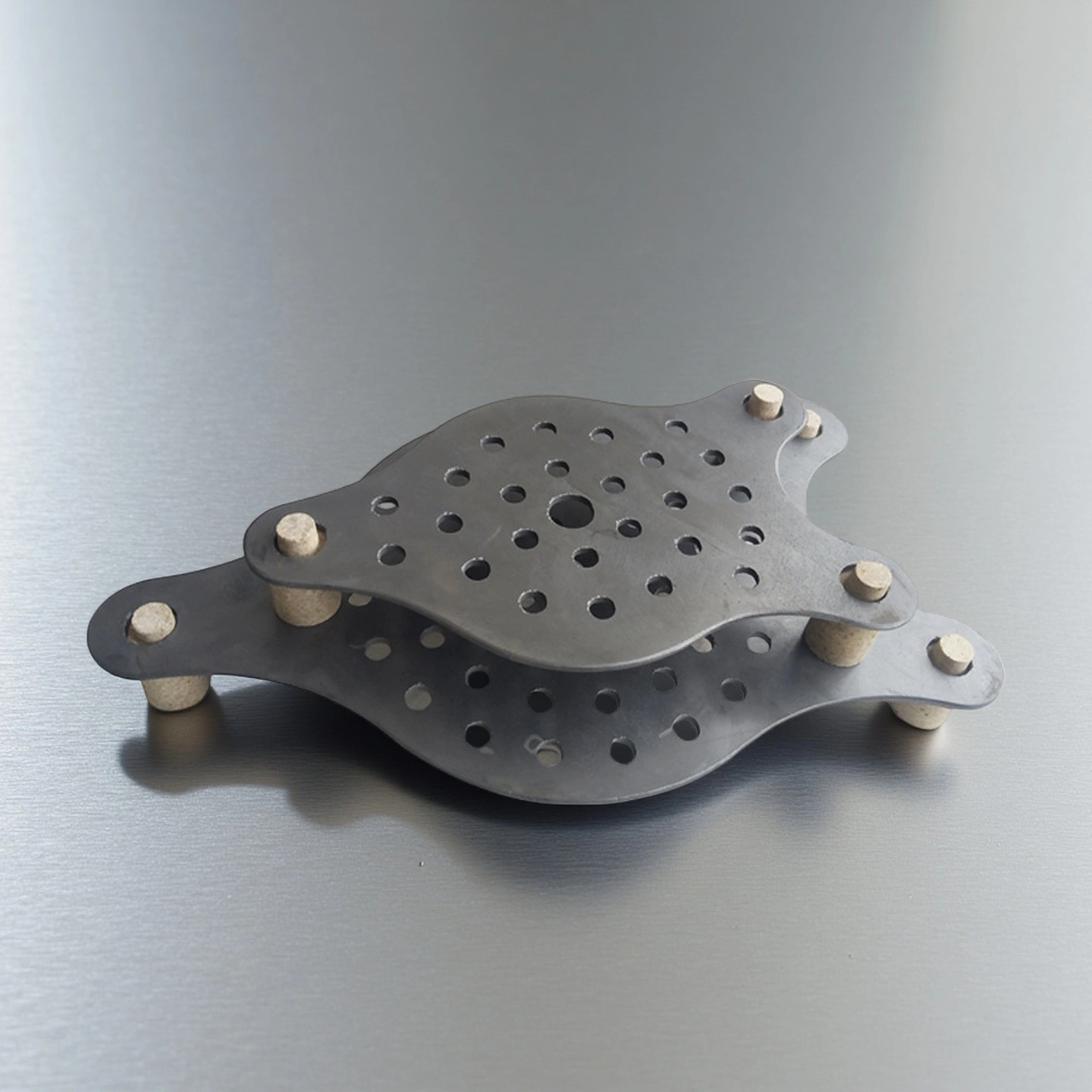

ADCERAX® Silicon Carbide Kiln Plate is designed to provide exceptional heat resistance and durability for industries that operate under extreme thermal and chemical conditions. Known for its excellent thermal shock resistance and mechanical strength, it is ideal for use in high-temperature environments such as furnaces, kilns, and reactors. Whether used in ceramics, metallurgy, or chemical processing, SiC Kiln Plate ensures reliable performance and long-lasting durability in demanding industrial applications.

Key Benefits of Silicon Carbide Kiln Plate

- Maximum Service Temperature: 1600°C

Silicon Carbide Kiln Plate can withstand temperatures up to 1600°C, ensuring consistent performance even in the most heat-intensive environments.

- Compressive Strength: 2500–3000 MPa

With impressive compressive strength, SiC Kiln Plate ensures superior structural integrity, even in high-pressure environments.

- Flexural Strength: 350–400 MPa

The excellent flexural strength of the kiln plate guarantees reliable performance in furnaces and kilns where heavy loads are common.

- Oxidation Resistance

It performs well even in high-oxygen environments, preventing degradation and maintaining long-term reliability in demanding conditions.

- Corrosion Resistance

The material's resistance to corrosion from molten metals and other industrial chemicals ensures durability and longevity, even in the harshest applications.

Technical Specifications of Silicon Carbide Kiln Plate

The Silicon Carbide Kiln Plate is engineered for optimal performance under extreme industrial conditions. Known for its exceptional thermal resistance, durability, and strength, it provides reliable solutions in high-temperature environments, including ceramics, metallurgy, and chemical processing.

| Property |

Specification |

| Material Composition |

High-Purity Silicon Carbide (≥99.9% SiC) |

| Density |

~3.15 g/cm³ |

| Thermal Conductivity |

120–180 W/m·K |

| Compressive Strength |

2500–3000 MPa |

| Flexural Strength |

350–400 MPa |

| Hardness |

Mohs hardness 9.5 |

| Maximum Service Temperature |

1600°C |

| Coefficient of Thermal Expansion (CTE) |

4.0–5.0 × 10⁻⁶/°C |

| Oxidation Resistance |

Excellent resistance to high-oxygen environments |

| Chemical Resistance |

Resistant to acids, bases, and molten metals |

| Thermal Shock Resistance |

High resistance to rapid temperature fluctuations |

| Surface Finish |

Smooth or textured, customizable |

| Durability |

Superior wear and corrosion resistance |

| Mechanical Strength |

Suitable for heavy-load applications |

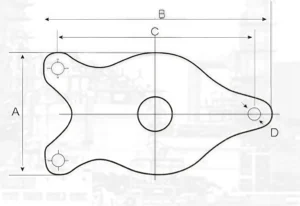

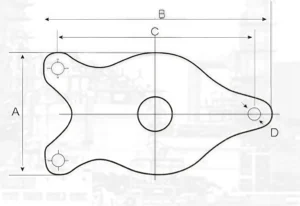

Dimensions of Silicon Carbide Kiln Plate

Packaging of Silicon Carbide Kiln Plate

Silicon Carbide Kiln Plate is carefully packed to ensure its safety during transit and handling. Each plate is first securely wrapped and then placed in sturdy cardboard boxes, providing protection from external pressure and impacts. The boxes are further reinforced with wooden crates, ensuring that SiC Kiln Plate arrives at its destination in perfect condition.

Solving Industry-Specific Application Challenges with ADCERAX® Silicon Carbide Kiln Plate

The Silicon Carbide Kiln Plate from ADCERAX® is designed to address the specific challenges faced by industries that operate under extreme heat and harsh conditions. Its exceptional durability, thermal shock resistance, and chemical resilience make it the go-to solution for applications in ceramics manufacturing, metallurgy, glass production, battery material processing, and chemical processing.

-

Ceramic Manufacturing: Optimized for High-Temperature Firing and Sintering

✅Key Advantages

1. Thermal Shock Resistance

The Silicon Carbide Kiln Plate can handle rapid temperature changes without cracking, ensuring stable performance in environments where extreme heating and cooling occur. This resistance minimizes the risk of downtime during the firing process.

2. High Mechanical Strength

With a flexural strength of 350–400 MPa, the Silicon Carbide Kiln Plate provides exceptional support during high-temperature sintering, maintaining structural integrity even under heavy loads. This reduces the likelihood of plate failure in the furnace.

3. Chemical Resistance

The material is highly resistant to corrosive chemicals commonly found in ceramic processing, such as acids and bases, ensuring the kiln plate’s longevity. This helps avoid plate degradation and maintains consistent firing quality.

✅ ️Problem Solved

In a large ceramic manufacturing plant, frequent kiln plate failures were causing production delays and increased maintenance costs due to cracks and chemical corrosion. The introduction of ADCERAX® Silicon Carbide Kiln Plates solved these issues by providing plates that withstood extreme temperature fluctuations without cracking, while also resisting the corrosive effects of chemical agents. This led to a reduction in downtime and maintenance, resulting in improved production efficiency and a noticeable decrease in operational costs over six months.

-

Metallurgical Industry: Furnace Linings for High-Temperature Metal Processing

✅Key Advantages

1. High-Temperature Endurance

The Silicon Carbide Kiln Plate can endure temperatures up to 1600°C, making it ideal for use in high-temperature metal smelting and casting applications. This feature ensures long-term performance without the risk of material failure in extreme heat.

2. Erosion Resistance

Silicon Carbide Kiln Plate is highly resistant to the erosion caused by molten metals and slag. Its wear resistance significantly reduces the frequency of replacements, ensuring consistent performance in harsh metal processing environments.

3. Corrosion Resistance

The material’s ability to resist chemical attacks from molten metals and high-temperature environments ensures a longer service life. This minimizes downtime and reduces the need for frequent furnace linings replacement in metal treatment processes.

✅ ️Problem Solved

A metallurgical company faced frequent failure of their furnace linings due to the aggressive chemical reactions between the molten metal and conventional kiln plates, leading to frequent downtime and replacement costs. After switching to ADCERAX® Silicon Carbide Kiln Plates, the company saw a significant reduction in the erosion of furnace linings, even under intense molten metal conditions. This led to extended maintenance intervals and improved productivity in their metal casting operations.

-

Chemical Processing: High-Performance Heat-Resistant Components

✅Key Advantages

1. Oxidation Resistance

The Silicon Carbide Kiln Plate is resistant to oxidation in high-oxygen environments, ensuring its stability and longevity in reactors and heat exchangers used in chemical processing. This provides reliable performance in environments where oxidation can quickly degrade other materials.

2. Corrosion Resistance

The plate’s exceptional resistance to aggressive chemicals, such as acids and bases commonly found in chemical reactors, ensures long-term durability. It helps maintain the operational integrity of chemical processing systems.

3. High-Temperature Stability

With the ability to withstand temperatures of up to 1600°C, Silicon Carbide Kiln Plates maintain their structural integrity in high-temperature reactors, ensuring that the heat treatment processes in chemical plants are not interrupted.

✅ ️Problem Solved

A chemical processing plant was dealing with frequent failures of their heat exchangers and reactors due to the aggressive corrosion from chemicals and high temperatures. The installation of ADCERAX® Silicon Carbide Kiln Plates solved this issue by providing highly durable components that withstood the harsh chemical environment while maintaining high-temperature stability. This led to a reduction in maintenance costs and ensured continuous operation without the need for frequent replacements.

User Guide for Proper Handling and Maintenance of ADCERAX® Silicon Carbide Kiln Plate

To ensure the long-lasting performance and optimal use of Silicon Carbide Kiln Plate, it's essential to follow proper handling, storage, and maintenance guidelines. ADCERAX® Silicon Carbide Kiln Plate is designed to meet the demands of high-temperature and chemically aggressive environments, but it requires careful attention during its usage and storage.

-

Proper Handling and Transportation

1. Avoid Impact Damage: Always handle Silicon Carbide Kiln Plate with care to prevent sudden impacts, which can lead to cracks or chips.

2. Use Protective Packaging: When transporting the plates, ensure they are securely packaged in their protective containers to minimize movement and potential damage during transit.

3. Lift with Proper Equipment: Use suitable lifting equipment to avoid placing unnecessary strain on the kiln plate during handling.

-

Storing for Maximum Longevity

1. Store in Dry Conditions: Keep Silicon Carbide Kiln Plate in a dry environment to prevent moisture exposure, which can affect its thermal and mechanical properties.

2. Avoid Direct Sunlight: Prolonged exposure to direct sunlight can lead to thermal expansion, so store the kiln plates away from heat sources.

3. Stack Correctly: When stacking Silicon Carbide Kiln Plate, make sure the plates are aligned and supported evenly to prevent warping or bending under pressure.

-

Operating SiC Kiln Plate Under High-Temperature Conditions

1. Control Heating and Cooling Rates: Gradually increase or decrease the temperature to prevent thermal shock, which can cause the kiln plate to crack or fail.

2. Monitor Temperature Fluctuations: Ensure the Silicon Carbide Kiln Plate is exposed to consistent temperature levels during operation to avoid damage due to sudden temperature changes.

3. Use in Designated Applications: Always use Silicon Carbide Kiln Plate within the recommended temperature range (up to 1600°C) to ensure optimal performance and durability.

-

Regular Maintenance and Inspection

1. Inspect for Cracks or Wear: Regularly check Silicon Carbide Kiln Plate for any signs of cracks or wear, especially after extended periods of use in high-temperature environments.

2. Clean After Use: After each use, allow the plate to cool before gently cleaning it with a dry cloth to remove any debris or residue that could affect its performance in future applications.

3. Prevent Chemical Exposure: Ensure that the kiln plate is not exposed to highly reactive chemicals or molten metals beyond the specified resistance limits to maintain its integrity.