ADCERAX® Silicon Carbide Mechanical Seal is a high-performance sealing solution designed for the most demanding industrial applications. Known for its exceptional resistance to wear, corrosion, and high temperatures, it ensures reliable operation in fluid handling systems across industries like chemical processing, oil and gas, and power generation. Engineered to withstand harsh environments, this seal significantly reduces downtime and maintenance costs, offering an extended operational lifespan.

Performance Characteristics of Silicon Carbide Mechanical Seal

-

Hardness Rating: With a hardness of 9.2 on the Mohs scale, SiC seals are significantly harder than most traditional materials, extending service life.

-

Temperature Resistance: Capable of withstanding temperatures up to 1600°C, SiC seals perform reliably in high-temperature operations, such as in power plants and oil refining.

-

Corrosion Resistance: SiC seals are effective in systems exposed to highly corrosive chemicals like acids and alkalis, reducing the risk of premature failure.

-

Reduced Maintenance: The exceptional wear resistance minimizes the need for frequent replacements, contributing to lower operational downtime.

-

Continuous Operation: With its thermal shock resistance, the seal can handle rapid temperature changes without cracking or failure.

Technical Specifications of Silicon Carbide Mechanical Seal

The Silicon Carbide Mechanical Seal is engineered to provide exceptional performance under the most demanding conditions. Designed to withstand extreme temperatures, pressures, and aggressive chemicals, it is ideal for use in industries such as chemical processing, oil & gas, and power generation.

| Property |

Specification |

| Material |

Silicon Carbide (SiC) |

| Hardness |

9.2 Mohs Scale |

| Temperature Resistance |

Up to 1600°C |

| Pressure Resistance |

Up to 200 bar |

| Chemical Resistance |

Acid, Alkali, Solvents |

| Thermal Expansion |

3.1 x 10⁻⁶ /°C (Coefficient) |

| Wear Resistance |

Excellent, low abrasion |

| Friction Coefficient |

< 0.1 |

| Density |

3.10 g/cm³ |

| Porosity |

< 0.5% |

| Flexural Strength |

650 MPa |

| Compressive Strength |

2500 MPa |

| Thermal Conductivity |

120 W/m·K |

| Electrically Conductive |

No (Insulator) |

| Corrosion Resistance |

Excellent in aggressive media |

Dimensions of Silicon Carbide Mechanical Seal

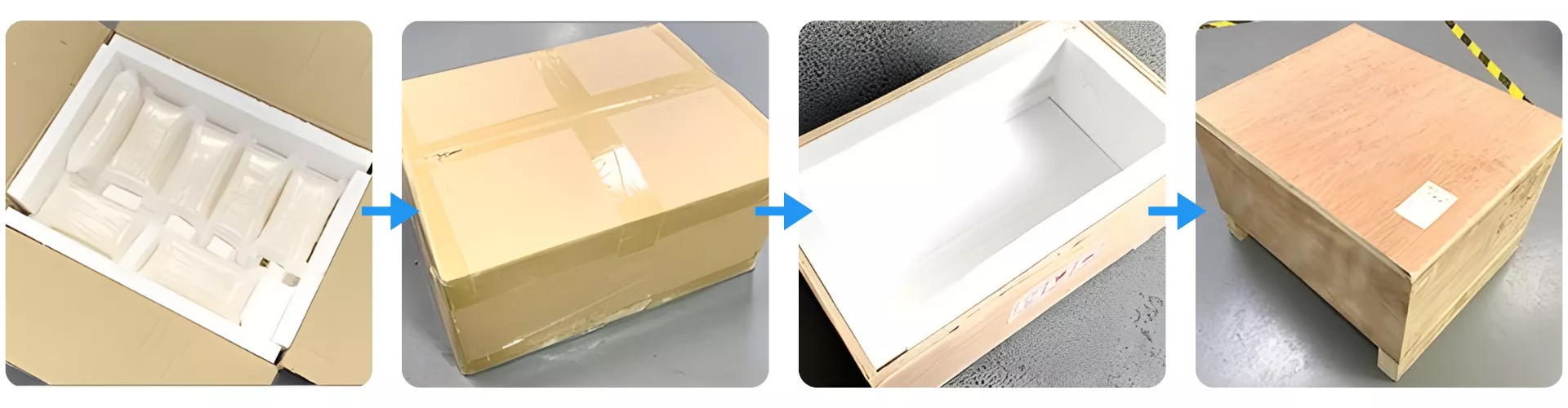

Packaging Method for Silicon Carbide Mechanical Seal

The Silicon Carbide Mechanical Seal is carefully packed to ensure safe and secure transportation. The packaging includes custom foam inserts to prevent damage during transit, ensuring that the seal arrives in perfect condition. Each unit is placed in a sturdy, sealed cardboard box, which is then reinforced with wooden crates for added protection.

Solving Industry Challenges with ADCERAX® Silicon Carbide Mechanical Seal

The Silicon Carbide Mechanical Seal from ADCERAX® is specifically designed to address the challenges faced by industrial sectors such as chemical processing, oil and gas, and power generation. These industries require seals that perform reliably under extreme conditions, including high pressures, temperatures, and exposure to aggressive chemicals.

-

Overcoming Chemical Corrosion Challenges in Chemical Processing

✅Key Advantages

1. Superior Chemical Resistance

The Silicon Carbide Mechanical Seal is highly resistant to a wide range of aggressive chemicals, including acids, alkalis, and solvents. This ensures long-lasting performance even in chemical plants that handle corrosive substances, where traditional seals would typically degrade quickly.

2. Enhanced Seal Longevity

SiC seals significantly extend the lifespan of pump systems by reducing the frequency of seal replacements. Their durability in harsh chemical environments minimizes operational interruptions and contributes to lower maintenance costs, which is crucial for ensuring continuous operation.

3. Leak-Free Operation in Aggressive Environments

By offering exceptional sealing integrity, the Silicon Carbide Mechanical Seal maintains a secure barrier between pumps and the surrounding environment, effectively preventing leaks of dangerous or corrosive chemicals. This is especially important for compliance with environmental and safety regulations.

✅ ️Problem Solved

In a recent case, a chemical processing plant faced continuous issues with traditional seals failing in corrosive chemical environments, leading to frequent downtime and expensive maintenance. By switching to ADCERAX® Silicon Carbide Mechanical Seals, the plant was able to drastically reduce seal failures and downtime. The seals' superior chemical resistance ensured a longer service life, which reduced maintenance costs by 30% and extended the time between replacements. The plant reported a 50% reduction in unplanned maintenance, allowing for more efficient and continuous operations.

-

Ensuring Reliability in High-Temperature Applications in Oil and Gas

✅Key Advantages

1. High-Temperature Stability

The Silicon Carbide Mechanical Seal can withstand extreme heat, up to 1600°C, which is essential in the oil and gas industry where high temperatures are common. This allows seals to function effectively in high-temperature environments without losing their sealing integrity.

2. Resilience Under High Pressure

Designed to handle high pressures (up to 200 bar or more), the SiC mechanical seal performs reliably even in deep wells or high-pressure pipelines, ensuring that the system remains leak-free and operates safely in hazardous conditions.

3. Reduced Risk of System Failure

The Silicon Carbide Mechanical Seal ensures the operational reliability of pumps and valves by preventing common issues such as seal failure due to thermal degradation. This improves system efficiency and safety, reducing the risk of costly breakdowns and maintaining productivity.

✅ ️Problem Solved

In an offshore oil rig, the pumps used for crude oil extraction were frequently experiencing seal failures due to high-pressure and high-temperature conditions. After switching to ADCERAX® Silicon Carbide Mechanical Seals, the oil rig saw zero seal failures during a 6-month trial period, despite operating in conditions exceeding 1500°C and 300 bar pressures. The SiC seals effectively eliminated leaks, resulting in a 40% reduction in downtime and 25% lower maintenance costs, ensuring smooth operations in a challenging environment.

-

Enhancing Pump Performance in Power Generation Systems

✅Key Advantages

1. Exceptional High-Pressure Resistance

The Silicon Carbide Mechanical Seal is engineered to perform under high-pressure conditions, commonly found in power generation plants. Its resistance to pressure ensures long-term performance in cooling pumps and other critical systems, maintaining system integrity even during peak operational loads.

2. Thermal Shock Resistance

The ability of SiC seals to withstand rapid temperature changes without cracking makes them ideal for power generation systems, where thermal cycles are common. This resistance helps maintain a consistent seal throughout the operational lifecycle.

3. Reduced Maintenance and Operational Downtime

By providing a long-lasting, reliable sealing solution, the Silicon Carbide Mechanical Seal reduces the need for frequent seal replacements and maintenance. This directly contributes to reducing downtime and optimizing the efficiency of power generation systems.

✅ ️Problem Solved

A nuclear power plant was struggling with frequent pump failures due to high-temperature fluctuations and high-pressure systems. After switching to ADCERAX® Silicon Carbide Mechanical Seals, the plant observed a 50% reduction in pump-related downtime. The seals’ thermal shock resistance ensured that they continued to perform reliably, even with rapid temperature changes, while their high-pressure resistance helped the pumps maintain stable operations. This resulted in significant operational cost savings and improved system reliability, ensuring uninterrupted power generation.

Essential User Guide for ADCERAX® Silicon Carbide Mechanical Seal

To ensure the long-lasting performance and reliability of the Silicon Carbide Mechanical Seal from ADCERAX®, it's important to follow specific usage and maintenance guidelines. This user guide provides essential information to help you install, maintain, and operate your seal in various industrial applications.

-

Installation Guidelines

1. Ensure Proper Alignment: Before installation, verify that the pump shaft is perfectly aligned with the housing. Misalignment can lead to uneven wear and seal failure.

2. Clean Installation Surface: Always clean the mounting surface of the pump thoroughly to prevent any contaminants from interfering with the seal's performance.

3. Use Proper Tools: Ensure that the installation tools used are designed for mechanical seal installation. This will help avoid damage to the seal during setup.

-

Operating Recommendations

1. Monitor Operating Conditions: Regularly monitor the temperature and pressure levels within the system to ensure that they remain within the recommended limits for the Silicon Carbide Mechanical Seal.

2. Prevent Dry Running: Always ensure that the seal is properly lubricated with the correct fluid before start-up to avoid damage caused by dry running.

3. Control Vibration: Excessive vibration can lead to premature wear of the seal. Make sure the system is operating smoothly with minimal vibrations.

-

Maintenance Tips

1. Inspect Regularly: Perform regular visual inspections to detect any signs of wear or leakage around the seal. Early detection helps avoid costly downtime.

2. Check Lubrication Levels: Ensure that the lubrication levels are sufficient to maintain the proper operation of the Silicon Carbide Mechanical Seal. Use only recommended lubricants.

3. Replace Worn Components: If the seal shows signs of significant wear or damage, replace it immediately to maintain system integrity.

-

Storage and Handling Instructions

1. Store in a Dry Area: Store the Silicon Carbide Mechanical Seal in a cool, dry place away from moisture to prevent damage.

2. Handle with Care: When handling the seal, avoid dropping or subjecting it to sudden impacts, as this can damage the ceramic material.

3. Protect from Contaminants: Ensure the seal is kept away from contaminants such as dust, dirt, or chemicals that could affect its performance during installation.

![]()