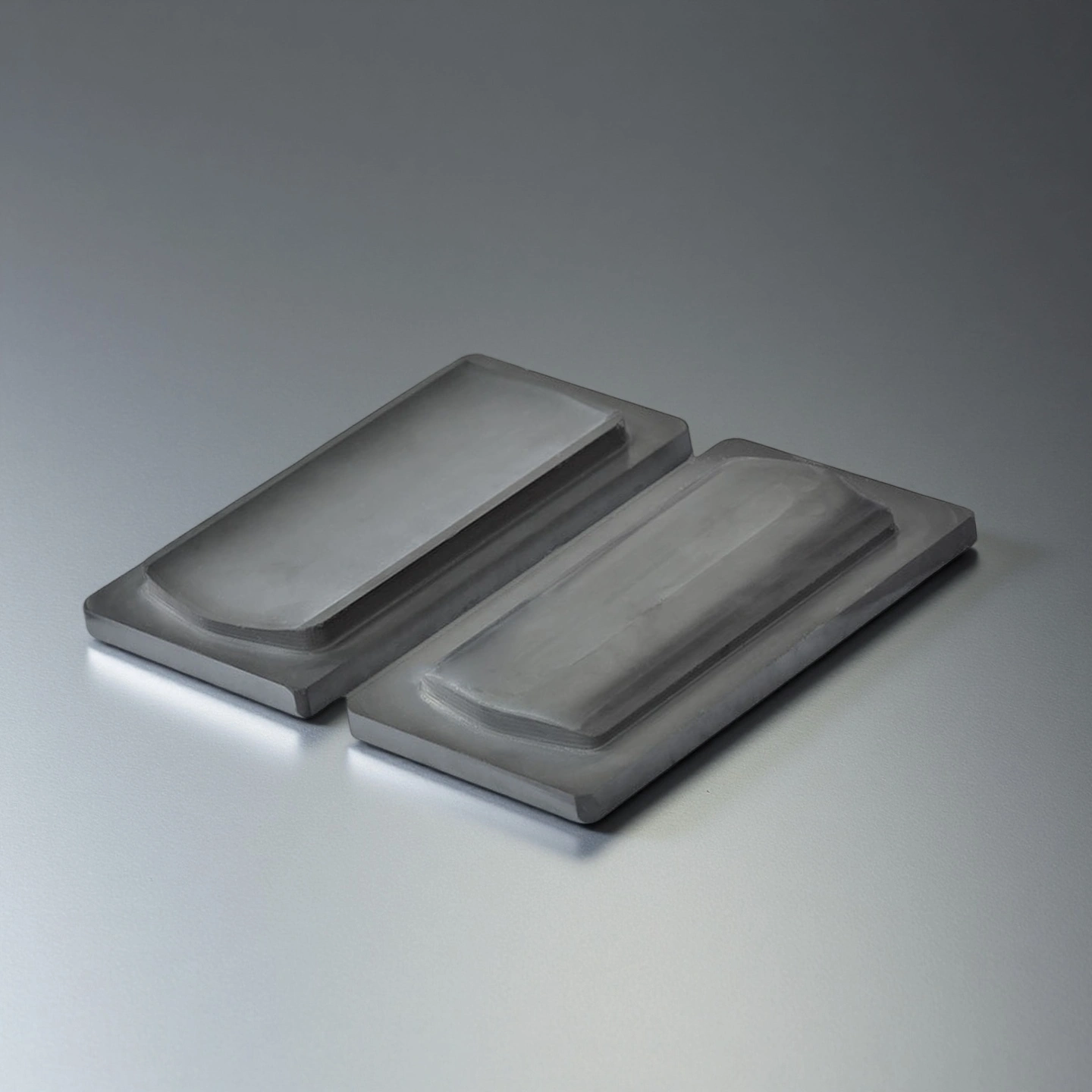

ADCERAX® Silicon Carbide Mold for Glass Molding supports high-temperature glass forming environments where 3D cover glass, curved automotive displays, and precision optical components require stable cavity geometry and consistent thermal behavior. Its material system enables uniform heat transfer and maintains structural integrity during repeated heating cycles, creating predictable forming conditions across complex surfaces. These characteristics help manufacturers achieve steady yield performance and reduce production interruptions as glass designs become more intricate and thermal loading becomes more demanding.

Key Features of Silicon Carbide Mold for Glass Molding

-

Efficient Heat Transfer

The mold provides a thermal conductivity of 120–150 W/m·K, allowing rapid and even heat flow across complex cavity surfaces. This minimizes thermal gradients that typically cause glass warpage during forming.

-

Dimensional Control Under Heat

With a thermal expansion coefficient of 4.0–4.5×10⁻⁶/K, the mold maintains stable geometry during high-temperature exposure. This reduces shape deviation and helps preserve cavity fidelity throughout extended production cycles.

-

High Hardness for Wear Resistance

With hardness levels of 23–26 GPa, the mold resists surface abrasion during repeated pressing cycles. This prevents micro-damage that can affect forming accuracy over long-term use.

Technical Specifications of Silicon Carbide Mold for Glass Molding

ADCERAX® Silicon Carbide Mold for Glass Molding is defined by a stable high-temperature material system that maintains structural rigidity, thermal uniformity, and surface integrity during repeated thermoforming cycles. Its microstructure, thermal properties, and mechanical strength support consistent forming quality across complex glass geometries in demanding industrial environments.

| Property |

Specification |

| Material Type |

RBSiC / RSiC |

| SiC Purity |

98.5–99.5% |

| Density |

2.95–3.10 g/cm³ |

| Hardness (HV0.5) |

23–26 GPa |

| Elastic Modulus |

380–420 GPa |

| Poisson’s Ratio |

0.17–0.19 |

| Thermal Conductivity |

120–150 W/m·K |

| Thermal Expansion Coefficient |

4.0–4.5×10⁻⁶/K |

| Maximum Working Temperature (Air) |

up to 1500°C |

| Maximum Working Temperature (Inert) |

up to 1700°C |

| Open Porosity |

<0.2% (RSiC), <1–2% (RBSiC) |

| Surface Roughness (Ra) |

0.2–0.8 μm |

| Cavity Profile Accuracy |

±0.02–0.05 mm |

| Flatness (Large Molds) |

0.03–0.08 mm |

| Thermal Shock Resistance |

200°C → 1200°C cycles |

Dimensions of Silicon Carbide Mold for Glass Molding

| Processing Precision |

| Inner/Outer Roundness |

Surface Roughness |

Perpendicularity |

Parallelism |

| 1µm |

10nm |

1µm |

1µm |

|

SiC Mold |

|

Model |

Outer Diameter (mm) |

Inner Diameter (mm) |

Height (mm) |

Number of Process Holes |

|

AT-SIC-MJ1001 |

14-65 |

5-50 |

20-60 |

1-10 |

Packaging Method of Silicon Carbide Mold for Glass Molding

Silicon Carbide Mold for Glass Molding is packed using layered foam protection, reinforced carton wrapping, and impact-resistant wooden crates to ensure safe handling during long-distance transport. Each mold is individually cushioned to prevent abrasion or vibration damage throughout shipment. All crates are pallet-secured and moisture-protected to maintain product integrity upon arrival.

ADCERAX® Silicon Carbide Mold for Glass Molding Resolves Heat-Forming Challenges in Advanced Glass Manufacturing

ADCERAX® Silicon Carbide Mold for Glass Molding supports high-precision thermoforming environments where curvature accuracy, thermal uniformity, and surface cleanliness directly affect yield. As glass components become thinner, larger, and more complex, forming processes face higher thermal loads and tighter geometric requirements.

-

Silicon Carbide Mold for Glass Molding in 3D Smartphone Cover Glass Hot-Press Forming

✅Key Advantages

1. Fast, uniform thermal response

Silicon Carbide Mold for Glass Molding provides a thermal conductivity of 120–150 W/m·K, so temperature differences across the mold surface can be kept within 5–7°C instead of double-digit gradients. This supports stable curvature formation during short hot-press cycles and reduces local overheating at edges and corners.

2. Stable geometry under rapid thermal cycling

With a thermal expansion coefficient of 4.0–4.5×10⁻⁶/K, cavity shape drift remains below 0.03 mm even after several hundred rapid cycles. This helps maintain consistent 3D cover glass curvature and limits shape-related scrap in long production campaigns.

3. Clean contact surface with lower defect formation

The low-porosity SiC structure (down to <0.2% in RSiC) avoids particle shedding that is common with graphite molds, keeping glass surfaces free from embedded inclusions. In typical smartphone lines this can cut defect-related rejection from around 10–12% to 3–5% for hot-pressed cover glass.

✅ ️Problem Solved

A high-volume smartphone glass producer replaced graphite tooling with ADCERAX® Silicon Carbide Mold for Glass Molding on its 3D cover glass hot-press lines. After the change, average mold life increased from roughly 40–60 cycles to 400–600 cycles before refurbishment, while curvature deviation at the glass edge was kept below 0.03 mm across extended runs. The rate of surface defects linked to mold particles dropped from around 10% of parts to below 4%, and unplanned mold-change stoppages were reduced from multiple events per week to occasional interventions per month. This improvement yielded more stable output per line and simplified process control for new model introductions.

-

Silicon Carbide Mold for Glass Molding in Automotive Curved Display and AR-HUD Glass Bending

✅Key Advantages

1. High stiffness maintained at bending temperature

Silicon Carbide Mold for Glass Molding retains more than 80% of its room-temperature elastic modulus at temperatures above 1200°C, so mid-span sag over wide molds stays under 0.05 mm after repeated exposure. This stiffness prevents gradual contour flattening that would otherwise change the intended display curvature.

2. Large-area thermal uniformity across wide panels

The combination of high thermal conductivity and controlled mold thickness allows center-to-edge temperature variation to be limited to around 5–8°C on wide automotive panels. This helps keep bending angles and panel bow within a tight distribution across glass widths in the 700–1000 mm range.

3. Consistent shape reproduction over long cycles

Flatness drift for large molds is typically maintained within 0.03–0.08 mm after several hundred bending cycles, compared with more than 0.10 mm drift often observed with conventional blocks. This allows tooling to run 3–4 times more cycles before regrinding, while still meeting curvature requirements for AR-HUD and cockpit displays.

✅ ️Problem Solved

An automotive display supplier adopting ADCERAX® Silicon Carbide Mold for Glass Molding for curved cluster glass reported a significant reduction in mid-span distortion during hot bending. After more than 300 cycles, mold flatness changes remained within 0.05 mm, whereas previous tooling exceeded 0.10 mm drift over similar usage. Center-to-edge curvature mismatch on finished glass dropped from typical values above 0.8 mm to around 0.3–0.4 mm, improving batch-to-batch uniformity for AR-HUD compatible panels. As a result, rework and re-bend rates for large curved screens were reduced by more than 50%, and mold maintenance intervals were extended, stabilizing production planning.

-

Silicon Carbide Mold for Glass Molding in Precision Aspheric Lens and Micro-Optics Glass Pressing

✅Key Advantages

1. Optical-grade surface retention over many cycles

Silicon Carbide Mold for Glass Molding supports surface finishes in the range of Ra 0.2–0.4 μm and maintains this level after several hundred pressing cycles. This allows aspheric and micro-optical features to be transferred with minimal loss of surface quality during extended tool life.

2. Micro-profile stability under thermal and mechanical load

Thanks to low thermal expansion and high hardness of 23–26 GPa, form error changes on critical optical zones can remain below 0.2–0.3 μm after repeated high-temperature pressing. This stability helps keep focal length and optical power variation within tight design limits across large batches.

3. Low porosity reducing defect-inducing inclusions

With open porosity down to <0.2% for recrystallized SiC, the mold surface generates far fewer particles than softer or more porous materials. Optical producers often see defect rates associated with mold-related inclusions fall from 8–10% to 2–3% when switching to this SiC material.

✅ ️Problem Solved

A precision optics manufacturer pressing small aspheric glass lenses moved from a graphite-based tooling set to ADCERAX® Silicon Carbide Mold for Glass Molding. Over more than 500 pressing cycles, measured surface roughness on the molded lenses stayed within Ra 0.25–0.35 μm, and form deviation increases remained below 0.3 μm on key optical zones. The share of lenses rejected due to inclusions traceable to mold particles dropped from around 9% to approximately 3%, and the need for corrective post-polishing steps per batch was reduced. This allowed the plant to run longer campaigns on a single mold set while holding optical performance inside specification windows.

ADCERAX® Silicon Carbide Mold for Glass Molding User Guide for Stable and Clean Forming Performance

The Silicon Carbide Mold for Glass Molding benefits from controlled handling, preparation, and maintenance practices that help preserve cavity integrity, thermal stability, and surface cleanliness throughout demanding forming cycles.

-

Preparation Before Forming Operations

1. Controlled pre-drying before high-temperature use

The mold should be placed in a dry and ventilated environment for conditioning before entering hot-press or bending cycles. This prevents moisture from causing surface steam micro-spall. Adequate drying helps maintain stable thermal response during the first heating ramp.

2. Surface inspection for debris or foreign particles

Before installation, ensure that the cavity area is free of dust, abrasives, or residues that may transfer onto softened glass. Foreign material can generate optical defects or leave imprints on curved surfaces. Visual checking helps protect the surface quality of formed glass.

3. Gradual initial heating for thermal equalization

During the first cycle of the shift, warm the mold gradually to allow uniform internal temperature distribution. This reduces early-cycle thermal shock and stabilizes heat flow across cavity features. Proper warm-up supports predictable forming geometry from the first pressed part.

-

Mold Handling and Installation Guidance

1. Protect edges and cavity features during lifting

Mechanical handling should avoid direct contact with the cavity edges, sharp contours, or precision radii, which are critical to profile accuracy. Abrupt impacts may affect dimensional repeatability. Use soft slings or protected clamps to retain shape stability.

2. Align mold and press tooling for uniform loading

Install the mold so that its support surfaces remain in full, even contact with the press frame or bending fixture. Uneven loading can cause thermal imbalance or gradual distortion over extended cycles. Correct alignment improves forming uniformity across the glass sheet.

3. Maintain clean mounting bases and fixtures

Ensure that all mounting areas are free from metal chips, refractory dust, or graphite debris before seating the mold. Foreign particles can create micro-tilt conditions that influence curvature. A clean interface contributes to repeatable press performance.

-

Operating Recommendations During Production

1. Maintain stable heating and cooling rates

Avoid extreme ramps that exceed normal process parameters to reduce stress on internal SiC structures. Stable thermal gradients help preserve long-cycle cavity consistency. Smooth transitions also decrease the chance of local thermal shock.

2. Monitor cavity condition during long campaigns

During extended runs, periodically observe cavity surfaces for embossed residues or thin film buildup from the glass composition. Such accumulation can alter contact patterns and affect curvature accuracy. Timely removal maintains consistent shaping quality.

3. Ensure glass placement repeatability

Position each glass piece consistently to avoid uneven load distribution that can influence shape outcome. Misalignment increases the risk of edge distortion during heating. Repeatable placement helps sustain predictable forming geometry.

-

Cleaning, Storage, and Preservation Practices

1. Use non-abrasive cleaning tools

Remove residues using soft fiber pads or approved non-abrasive tools to avoid scratching fine cavity textures. Aggressive tools may alter local contours. Proper cleaning preserves optical-grade surface finish where required.

2. Store molds in dry, dust-free conditions

Place molds in protected storage areas to prevent dust accumulation or moisture absorption, both of which may affect the next production start. Clean storage supports surface cleanliness and reduces preparation time.

3. Avoid long exposure to corrosive environments

Prevent extended contact with strong acids, alkalis, or corrosive fumes, as these may alter surface behavior over time. Chemically inert storage conditions retain the mold’s long-term stability for future cycles.

![]()