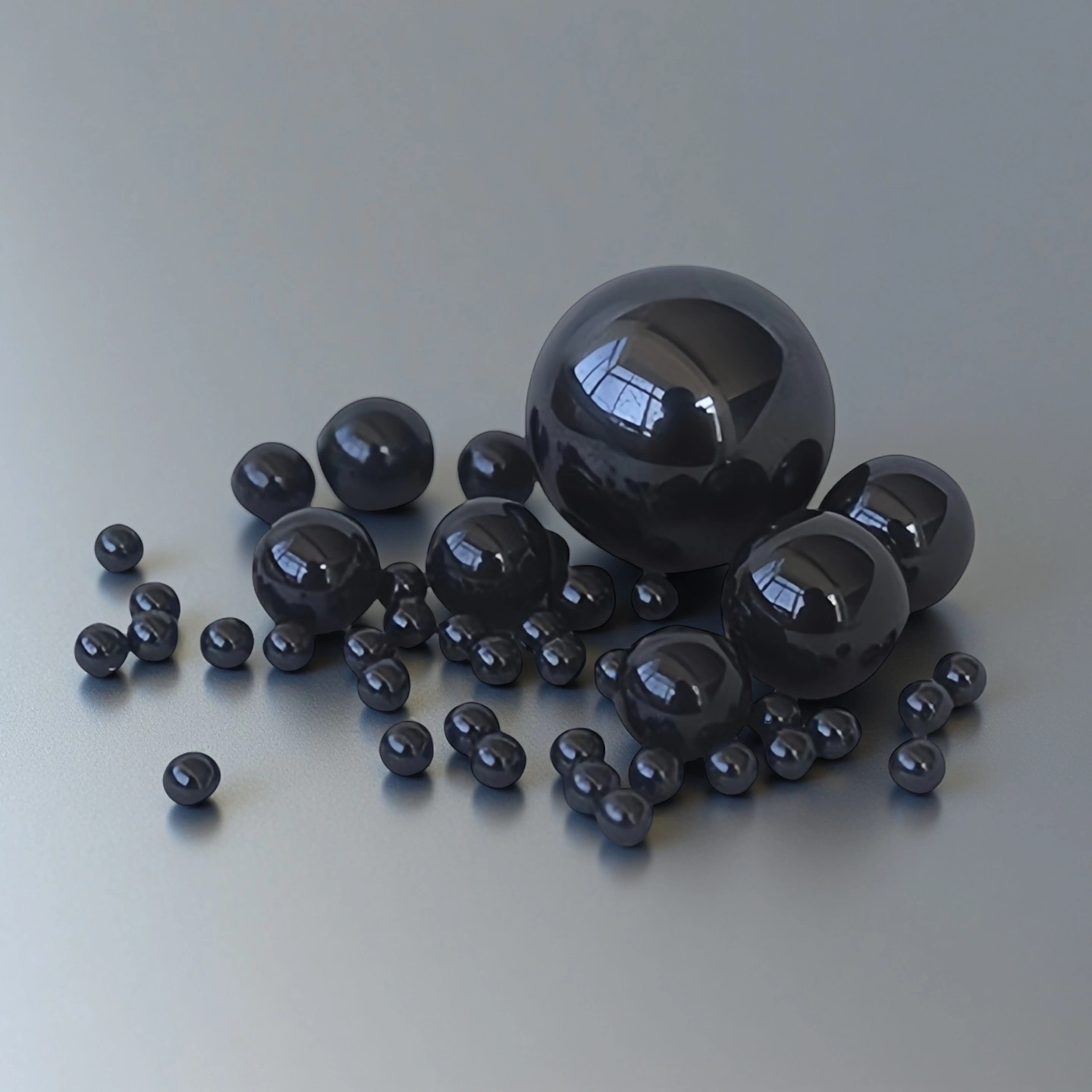

Silicon nitride bearing balls are ceramic rolling elements specifically engineered for hybrid and full-ceramic bearing assemblies, where they function as the load-transmitting and motion-determining components inside the bearing structure.

Unlike metallic counterparts, these balls are optimized for high rotational velocity, electrical insulation, and endurance under marginal lubrication or contaminated environments. They are manufactured to ISO 3290-2 Grade G5–G16 precision through isostatic pressing and gas-pressure sintering, ensuring sub-micron roundness and uniform microstructure for dynamic balance at ultra-high speeds.

Silicon Nitride Bearing Balls Benefits

-

High DN-Value Endurance: Designed for spindle and traction bearing systems operating above 1.8–2.2 million DN, minimizing centrifugal load on raceways and allowing continuous operation at extreme speeds without geometric distortion.

-

Electrically Insulated Operation: The non-conductive Si₃N₄ lattice prevents electrical discharge machining (EDM) and fluting damage in inverter-driven motors, reducing current-induced bearing failure rates by over 90% compared with steel.

-

Stable Contact Geometry: Maintains a consistent Hertzian stress field even under axial preload or temperature gradient, which effectively lowers cage wear and prevents false brinelling during dynamic acceleration cycles.

-

Oil-Starved Reliability: Sustains a thin-film lubrication regime under λ ratios below 1.0, maintaining surface integrity during transient or intermittent lubrication conditions where steel bearings would seize.

-

Extended Fatigue Life: Demonstrates an L₁₀ life over 10 times higher than steel bearings under contaminated lubrication tests, attributed to lower contact stress, minimal adhesion wear, and superior rolling fatigue resistance.

Si3N4 Bearing Balls Properties

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

Ceramic Si3N4 Bearing Balls Specifications

| Silicon Nitride Ball | |

| Item No. | Diameter(mm) |

| AT-DHG-Q001 | 0.1-0.2 |

| AT-DHG-Q002 | 0.2-0.3 |

| AT-DHG-Q003 | 0.3-0.4 |

| AT-DHG-Q004 | 0.4-0.5 |

| AT-DHG-Q005 | 0.5-0.6 |

| AT-DHG-Q006 | 0.6-0.7 |

| AT-DHG-Q007 | 0.7-0.8 |

| AT-DHG-Q008 | 0.8-1.0 |

| AT-DHG-Q009 | 1.0-1.2 |

| AT-DHG-Q010 | 1.2-1.4 |

| AT-DHG-Q011 | 0.794 |

| AT-DHG-Q012 | 1.191 |

| AT-DHG-Q013 | 1.588 |

| AT-DHG-Q014 | 1.984 |

| AT-DHG-Q015 | 2.000 |

| AT-DHG-Q016 | 2.381 |

| AT-DHG-Q017 | 2.500 |

| AT-DHG-Q018 | 2.778 |

| AT-DHG-Q019 | 3.000 |

| AT-DHG-Q020 | 3.175 |

| AT-DHG-Q021 | 3.500 |

| AT-DHG-Q022 | 3.969 |

| AT-DHG-Q023 | 4.000 |

| AT-DHG-Q024 | 4.500 |

| AT-DHG-Q025 | 4.763 |

| AT-DHG-Q026 | 5.000 |

| AT-DHG-Q027 | 5.556 |

| AT-DHG-Q028 | 5.953 |

| AT-DHG-Q029 | 6.000 |

| AT-DHG-Q030 | 6.350 |

| AT-DHG-Q031 | 6.747 |

| AT-DHG-Q032 | 7.000 |

| AT-DHG-Q033 | 7.144 |

| AT-DHG-Q034 | 7.500 |

| AT-DHG-Q035 | 7.938 |

| AT-DHG-Q036 | 8.000 |

| AT-DHG-Q037 | 8.334 |

| AT-DHG-Q038 | 8.731 |

| AT-DHG-Q039 | 9.000 |

| AT-DHG-Q040 | 9.128 |

| AT-DHG-Q041 | 9.525 |

| AT-DHG-Q042 | 9.922 |

| AT-DHG-Q043 | 10.000 |

| AT-DHG-Q044 | 10.319 |

| AT-DHG-Q045 | 11.000 |

| AT-DHG-Q046 | 11.113 |

| AT-DHG-Q047 | 11.509 |

| AT-DHG-Q048 | 11.906 |

| AT-DHG-Q049 | 12.000 |

| AT-DHG-Q050 | 12.303 |

| AT-DHG-Q051 | 12.700 |

| AT-DHG-Q052 | 13.494 |

| AT-DHG-Q053 | 14.288 |

| AT-DHG-Q054 | 15.081 |

| AT-DHG-Q055 | 15.875 |

| AT-DHG-Q056 | 16.000 |

| AT-DHG-Q057 | 16.669 |

| AT-DHG-Q058 | 17.462 |

| AT-DHG-Q059 | 18.256 |

| AT-DHG-Q060 | 19.050 |

| AT-DHG-Q061 | 19.844 |

| AT-DHG-Q062 | 20.000 |

| AT-DHG-Q063 | 20.638 |

| AT-DHG-Q064 | 21.431 |

| AT-DHG-Q065 | 22.225 |

| AT-DHG-Q066 | 23.019 |

| AT-DHG-Q067 | 23.813 |

| AT-DHG-Q068 | 24.000 |

| AT-DHG-Q069 | 24.606 |

| AT-DHG-Q070 | 25.000 |

| AT-DHG-Q071 | 25.400 |

| AT-DHG-Q072 | 26.988 |

| AT-DHG-Q073 | 27.000 |

| AT-DHG-Q074 | 28.575 |

| AT-DHG-Q075 | 30.000 |

| AT-DHG-Q076 | 30.163 |

| AT-DHG-Q077 | 31.750 |

| AT-DHG-Q078 | 33.338 |

| AT-DHG-Q079 | 34.925 |

| AT-DHG-Q080 | 36.513 |

| AT-DHG-Q081 | 38.100 |

| AT-DHG-Q082 | 39.688 |

| AT-DHG-Q083 | 40.000 |

| AT-DHG-Q084 | 41.275 |

| AT-DHG-Q085 | 42.863 |

| AT-DHG-Q086 | 44.450 |

| AT-DHG-Q087 | 45.000 |

| AT-DHG-Q088 | 47.625 |

| AT-DHG-Q089 | 50.800 |

| AT-DHG-Q090 | 53.975 |

Si3N4 Bearing Balls Packaging

- Anti-static sealed PE bags

- Foam-padded inner box with product label