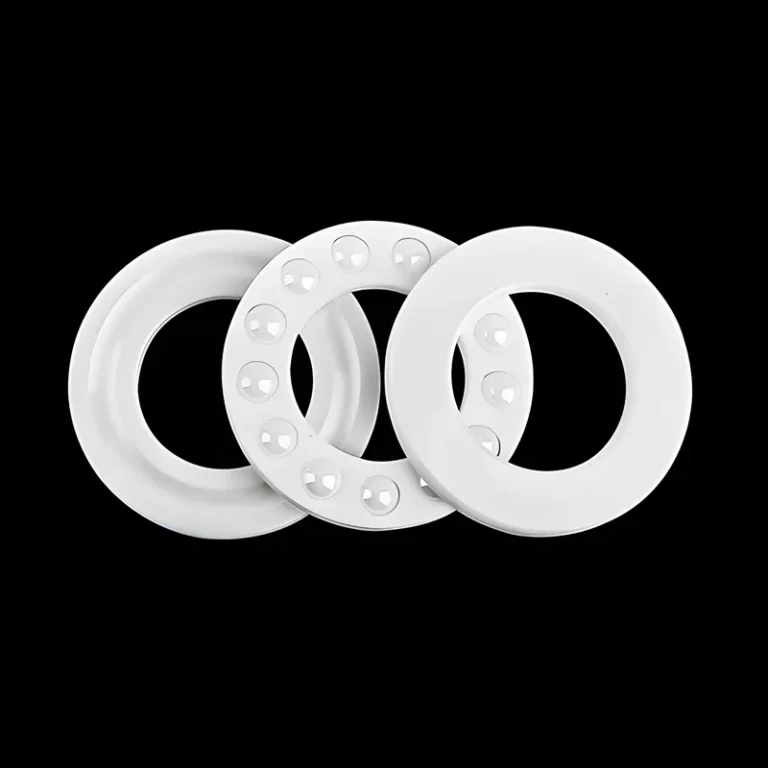

Silicon nitride bearing rollers are precision-engineered ceramic rolling elements made from Si₃N₄ (silicon nitride) material. They are used inside high-speed bearings, spindle assemblies, motors, pumps, and turbomachinery where metal rollers cannot meet the demands of temperature, corrosion, or electrical insulation.

Silicon Nitride Bearing Rollers Benefits

- Low Mass for High RPM

Silicon nitride rollers are approximately 60% lighter than steel, with a density of around 3.2 g/cm³, effectively lowering centrifugal forces and reducing contact stress during high-speed rotation. This lower mass allows spindles and motors to achieve higher acceleration and deceleration rates with less energy loss. The reduced dynamic load also decreases bearing noise and vibration, extending lubricant life and mechanical endurance in continuous-operation systems. - Electrical Insulation

The inherent electrical resistivity of Si₃N₄ (~10¹² Ω·cm) prevents stray-current discharge and EDM pitting in inverter-driven motors and generators, where steel paths often suffer from surface fluting. By isolating the rolling elements electrically, silicon nitride rollers eliminate current leakage through bearing races, thus prolonging bearing and motor lifespan, particularly in variable-frequency drive (VFD) applications. - Surface Finish Control

Each roller can be precision-polished to surface finishes as fine as Ra ≤ 0.02 µm, ensuring stable friction characteristics and rapid run-in. The ultra-smooth surface reduces asperity contact and micro-scuffing under boundary lubrication, leading to consistent torque and quieter operation. Such surface control is critical for high-speed spindles, aerospace gyros, and vacuum pumps operating with minimal lubrication films. - Geometric Precision

Tight roundness and cylindricity tolerances (often within ±0.001 mm) maintain a stable contact ellipse and minimize runout, vibration, and uneven load distribution. This high-level geometric precision ensures predictable preload behaviour, improved dynamic balance, and reduced resonance under extreme speeds, making these rollers suitable for precision CNC spindles and medical device actuators. - Corrosion and Chemical Tolerance

Silicon nitride is chemically inert to most acids, alkalis, and moisture, maintaining surface integrity where bearing steels corrode or pit. In neutral or mildly acidic environments, Si₃N₄ demonstrates long-term dimensional stability and low wear rates, making it ideal for process pumps, marine drives, and humid cleanroom environments. The material’s stable oxide layer prevents reaction with lubricants, ensuring consistent friction and reduced contamination risk.

Silicon Nitride Bearing Rollers Properties

1. Silicon Nitride Bearing Rollers Technical Data

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

2. Roller Grade Specifications (Unit: μm)

| Tolerance Grade | Ra | ||

|---|---|---|---|

| Rolling Surface (max) | End Face (max) | Chamfer (max) | |

| 0 | 0.1 | 0.125 | 1.25 |

| I | 0.125 | 1.16 | 1.25 |

| II | 0.16 | 0.25 | 2.5 |

| III | 0.25 | 0.32 | 2.5 |

Si3N4 Bearing Roller Specifications

| Silicon Nitride Bearing Rollers | ||

| Item No. | Diameter(mm) | Height(mm) |

| AT-SIN-GZ001 | 3 | 4 |

| AT-SIN-GZ002 | 3 | 5 |

| AT-SIN-GZ003 | 3 | 5.5 |

| AT-SIN-GZ004 | 5 | 6.5 |

| AT-SIN-GZ005 | 5 | 8 |

| AT-SIN-GZ006 | 10 | 10 |

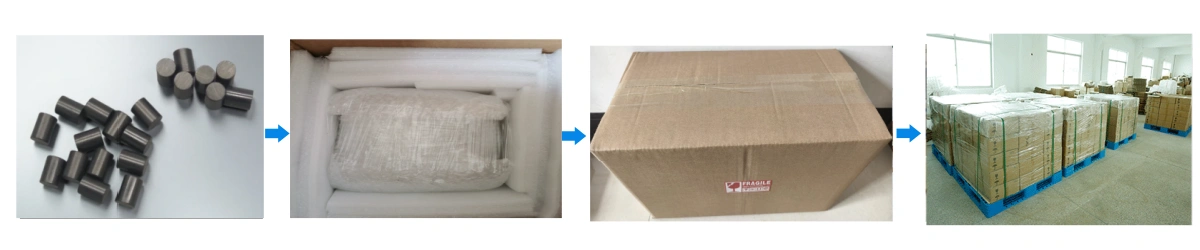

Si₃N₄ Bearing Ceramic Rollers Packaging

- Each roller is individually packed in anti-static foam trays.

- Sealed and moisture-proof packaging is available for export.