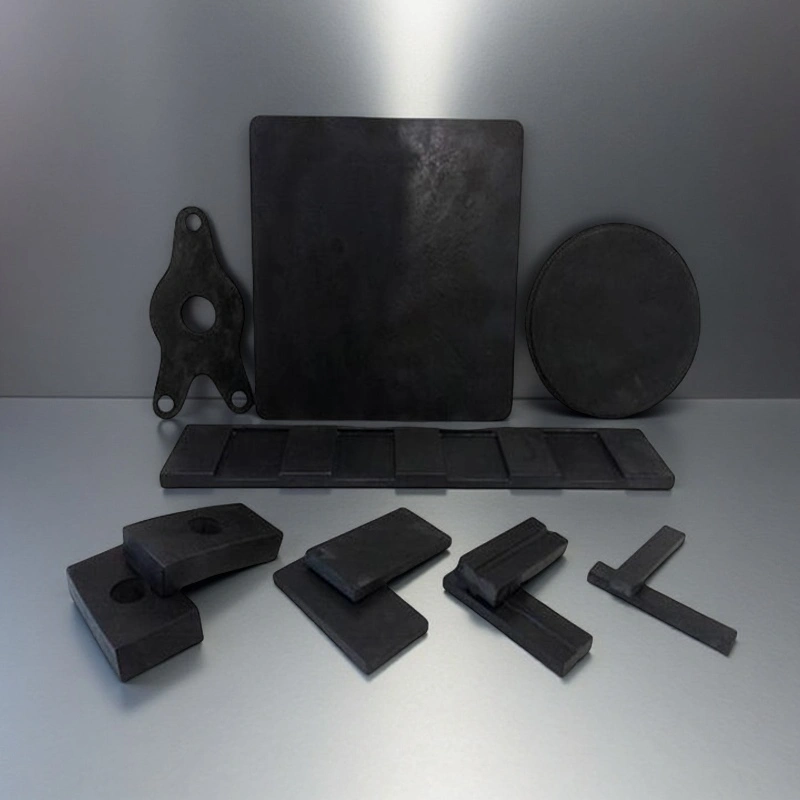

ADCERAX® Nitride Bonded Silicon Carbide Kiln Plate is engineered for high-performance applications in industrial sintering processes. Designed to withstand extreme temperatures and harsh environments, it offers exceptional thermal stability and mechanical strength. Widely used in ceramic and metallurgy industries, this kiln plate provides reliable support for materials during high-temperature sintering, ensuring stable, consistent results throughout the process.

Key Benefits of Nitride Bonded Silicon Carbide Kiln Plate

-

High Temperature Resistance: Withstands Up to 1500°C

-

The NBSiC Kiln Plate maintains its integrity even at temperatures exceeding 1500°C, making it perfect for extreme high-temperature sintering.

-

With a melting point well above 2000°C, it ensures stable performance under intense furnace conditions, preventing deformation.

-

-

Excellent Thermal Shock Resistance: Minimizes Cracking Risks

-

The unique combination of SiC and Si₃N₄ gives the NBSiC Kiln Plate excellent resistance to thermal shock, allowing it to endure rapid temperature changes without cracking.

-

This feature is especially important when the kiln undergoes frequent temperature cycles during production.

-

-

Superior Mechanical Strength: Supports Heavy Loads

-

NBSiC Kiln Plate offers high compressive strength (350 MPa at 1600°C) that allows it to support heavy ceramic or metal materials during the sintering process.

-

This robust strength helps minimize deflection under load, ensuring stable support and prolonged furnace use.

-

Technical Specifications of Nitride Bonded Silicon Carbide Kiln Plate

The Nitride Bonded Silicon Carbide Kiln Plate is engineered to deliver outstanding performance in high-temperature and demanding industrial sintering environments. Designed with a composite of SiC and Si₃N₄, it offers superior thermal stability, mechanical strength, and excellent corrosion resistance.

| Property | Specification |

|---|---|

| Maximum Operating Temperature | 1500°C |

| Melting Point | Over 2000°C |

| Thermal Expansion Coefficient | 2.7 x 10⁻⁶ /°C |

| Compressive Strength | 350 MPa at 1600°C |

| Flexural Strength | High (specific value TBD by testing) |

| Thermal Shock Resistance | High resistance to rapid temperature changes |

| Hardness | ≥9 Mohs |

| Density | 3.2 g/cm³ |

| Corrosion Resistance | Excellent in both acidic and alkaline environments |

| Oxidation Resistance | Stable at high temperatures in oxidizing environments |

| Electrical Insulation | Good (suitable for electrical applications) |

| Surface Finish | Smooth and non-contaminating |

| Surface Roughness | ≤0.2 µm (Ra) |

| Volume Stability | Stable under high thermal cycles |

| Wear Resistance | High durability in abrasive environments |

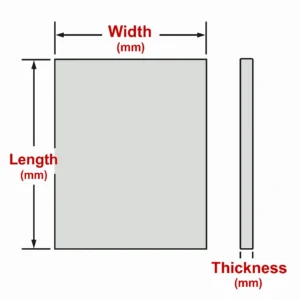

Dimensions of Nitride Bonded Silicon Carbide Kiln Plate

| Square NBSIC Refractory Plate | ||

| Item No. | Length(mm) | Width (mm) |

| AT-SIC-PB001 | 200 | 200 |

| AT-SIC-PB002 | 250 | 250 |

| AT-SIC-PB003 | 270 | 270 |

| AT-SIC-PB004 | 280 | 280 |

| AT-SIC-PB005 | 290 | 290 |

| AT-SIC-PB006 | 300 | 280 |

| AT-SIC-PB007 | 300 | 300 |

| AT-SIC-PB008 | 310 | 300 |

| AT-SIC-PB009 | 310 | 310 |

| AT-SIC-PB010 | 320 | 300 |

| AT-SIC-PB011 | 320 | 320 |

| AT-SIC-PB012 | 340 | 340 |

| AT-SIC-PB013 | 350 | 300 |

| AT-SIC-PB014 | 350 | 350 |

| AT-SIC-PB015 | 360 | 360 |

| AT-SIC-PB016 | 370 | 240 |

| AT-SIC-PB017 | 382 | 382 |

| AT-SIC-PB018 | 390 | 290 |

| AT-SIC-PB019 | 390 | 380 |

| AT-SIC-PB020 | 390 | 390 |

| AT-SIC-PB021 | 395 | 295 |

| AT-SIC-PB022 | 400 | 300 |

| AT-SIC-PB023 | 400 | 350 |

| AT-SIC-PB024 | 400 | 370 |

| AT-SIC-PB025 | 400 | 380 |

| AT-SIC-PB026 | 400 | 400 |

| AT-SIC-PB027 | 410 | 180 |

| AT-SIC-PB028 | 410 | 400 |

| AT-SIC-PB029 | 410 | 410 |

| AT-SIC-PB030 | 420 | 370 |

| AT-SIC-PB031 | 420 | 380 |

| AT-SIC-PB032 | 420 | 400 |

| AT-SIC-PB033 | 420 | 420 |

| AT-SIC-PB034 | 430 | 330 |

| AT-SIC-PB035 | 430 | 380 |

| AT-SIC-PB036 | 430 | 390 |

| AT-SIC-PB037 | 430 | 400 |

| AT-SIC-PB038 | 430 | 420 |

| AT-SIC-PB039 | 440 | 340 |

| AT-SIC-PB040 | 440 | 390 |

| AT-SIC-PB041 | 440 | 420 |

| AT-SIC-PB042 | 450 | 300 |

| AT-SIC-PB043 | 450 | 340 |

| AT-SIC-PB044 | 450 | 350 |

| AT-SIC-PB045 | 450 | 380 |

| AT-SIC-PB046 | 450 | 400 |

| AT-SIC-PB047 | 450 | 420 |

| AT-SIC-PB048 | 450 | 450 |

| AT-SIC-PB049 | 460 | 350 |

| AT-SIC-PB050 | 460 | 360 |

| AT-SIC-PB051 | 460 | 370 |

| AT-SIC-PB052 | 460 | 390 |

| AT-SIC-PB053 | 460 | 400 |

| AT-SIC-PB054 | 460 | 420 |

| AT-SIC-PB055 | 460 | 450 |

| AT-SIC-PB056 | 460 | 460 |

| AT-SIC-PB057 | 465 | 380 |

| AT-SIC-PB058 | 470 | 300 |

| AT-SIC-PB059 | 470 | 330 |

| AT-SIC-PB060 | 470 | 390 |

| AT-SIC-PB061 | 470 | 400 |

| AT-SIC-PB062 | 475 | 475 |

| AT-SIC-PB063 | 480 | 360 |

| AT-SIC-PB064 | 480 | 370 |

| AT-SIC-PB065 | 480 | 380 |

| AT-SIC-PB066 | 480 | 390 |

| AT-SIC-PB067 | 480 | 400 |

| AT-SIC-PB068 | 480 | 420 |

| AT-SIC-PB069 | 480 | 450 |

| AT-SIC-PB070 | 480 | 480 |

| AT-SIC-PB071 | 490 | 360 |

| AT-SIC-PB072 | 490 | 400 |

| AT-SIC-PB073 | 495 | 445 |

| AT-SIC-PB074 | 500 | 260 |

| AT-SIC-PB075 | 500 | 360 |

| AT-SIC-PB076 | 500 | 370 |

| AT-SIC-PB077 | 500 | 380 |

| AT-SIC-PB078 | 500 | 400 |

| AT-SIC-PB079 | 500 | 420 |

| AT-SIC-PB080 | 500 | 430 |

| AT-SIC-PB081 | 500 | 450 |

| AT-SIC-PB082 | 500 | 460 |

| AT-SIC-PB083 | 500 | 480 |

| AT-SIC-PB084 | 500 | 500 |

| AT-SIC-PB085 | 505 | 375 |

| AT-SIC-PB086 | 510 | 390 |

| AT-SIC-PB087 | 520 | 370 |

| AT-SIC-PB088 | 520 | 400 |

| AT-SIC-PB089 | 520 | 480 |

| AT-SIC-PB090 | 520 | 500 |

| AT-SIC-PB091 | 525 | 485 |

| AT-SIC-PB092 | 530 | 330 |

| AT-SIC-PB093 | 530 | 335 |

| AT-SIC-PB094 | 530 | 500 |

| AT-SIC-PB095 | 535 | 175 |

| AT-SIC-PB096 | 540 | 370 |

| AT-SIC-PB097 | 540 | 420 |

| AT-SIC-PB098 | 550 | 100 |

| AT-SIC-PB099 | 550 | 200 |

| AT-SIC-PB100 | 550 | 300 |

| AT-SIC-PB101 | 550 | 330 |

| AT-SIC-PB102 | 550 | 370 |

| AT-SIC-PB103 | 550 | 410 |

| AT-SIC-PB104 | 550 | 420 |

| AT-SIC-PB105 | 550 | 450 |

| AT-SIC-PB106 | 550 | 500 |

| AT-SIC-PB107 | 560 | 200 |

| AT-SIC-PB108 | 560 | 480 |

| AT-SIC-PB109 | 570 | 460 |

| AT-SIC-PB110 | 570 | 500 |

| AT-SIC-PB111 | 570 | 550 |

| AT-SIC-PB112 | 580 | 430 |

| AT-SIC-PB113 | 580 | 470 |

| AT-SIC-PB114 | 580 | 500 |

| AT-SIC-PB115 | 590 | 510 |

| AT-SIC-PB116 | 590 | 520 |

| AT-SIC-PB117 | 600 | 120 |

| AT-SIC-PB118 | 600 | 200 |

| AT-SIC-PB119 | 600 | 300 |

| AT-SIC-PB120 | 600 | 305 |

| AT-SIC-PB121 | 600 | 400 |

| AT-SIC-PB122 | 600 | 500 |

| AT-SIC-PB123 | 600 | 550 |

| AT-SIC-PB124 | 600 | 600 |

| AT-SIC-PB125 | 610 | 240 |

| AT-SIC-PB126 | 610 | 400 |

| AT-SIC-PB127 | 610 | 480 |

| AT-SIC-PB128 | 620 | 560 |

| AT-SIC-PB129 | 620 | 570 |

| AT-SIC-PB130 | 620 | 600 |

| AT-SIC-PB131 | 630 | 410 |

| AT-SIC-PB132 | 650 | 400 |

| AT-SIC-PB133 | 650 | 600 |

| AT-SIC-PB134 | 650 | 650 |

| AT-SIC-PB135 | 660 | 340 |

| AT-SIC-PB136 | 660 | 520 |

| AT-SIC-PB137 | 665 | 500 |

| AT-SIC-PB138 | 670 | 360 |

| AT-SIC-PB139 | 700 | 600 |

| AT-SIC-PB140 | 720 | 400 |

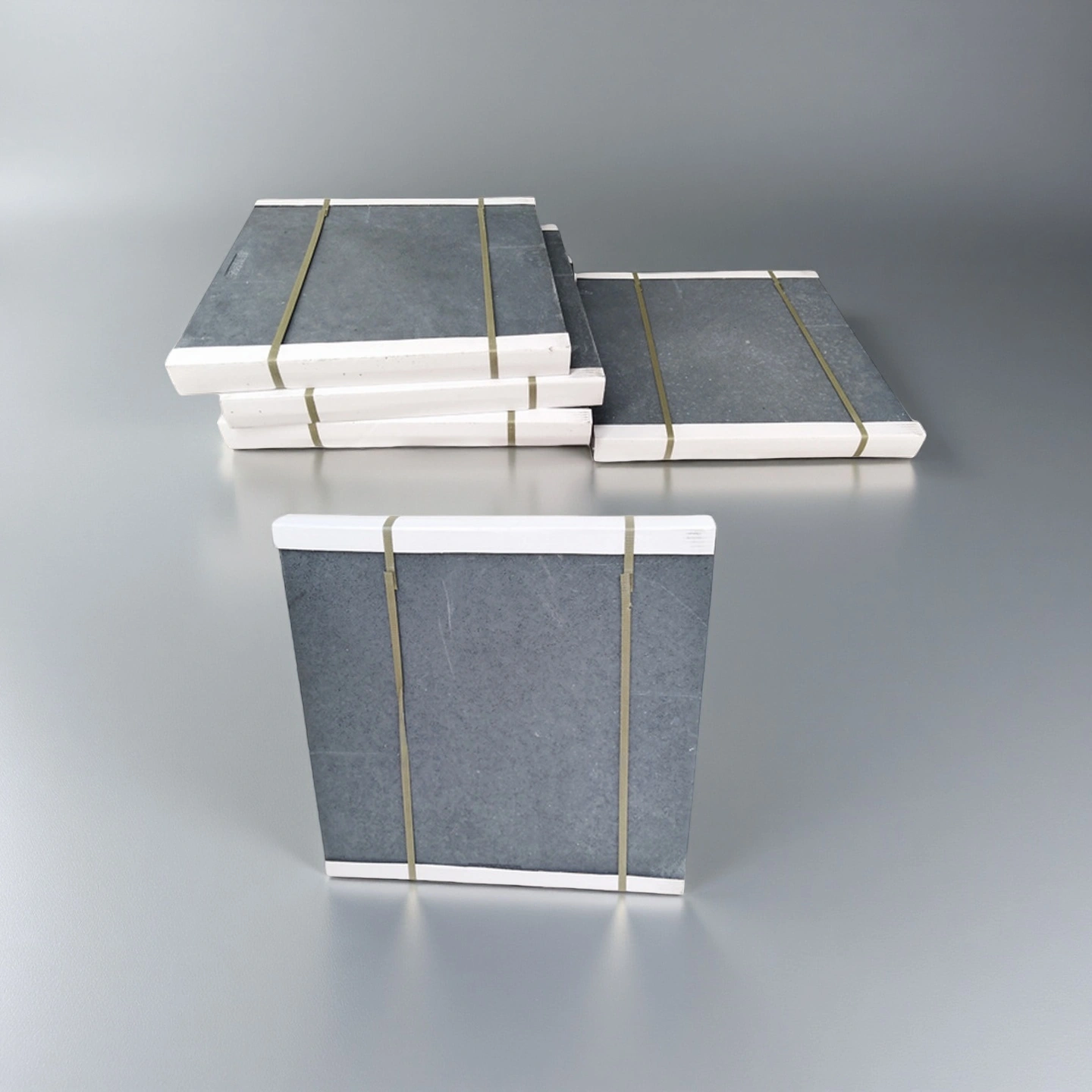

Packaging of Nitride Bonded Silicon Carbide Kiln Plate

The Nitride Bonded Silicon Carbide Kiln Plate is carefully packaged to ensure safe delivery. It is first wrapped in protective materials, then placed in sturdy cartons to prevent damage during transportation. Finally, the plates are secured in wooden crates for added protection, ensuring they arrive in perfect condition for use.