Silicon nitride ball bearings are precision bearings that use silicon nitride (Si₃N₄) ceramic balls instead of traditional steel balls. Silicon nitride is a high-performance advanced ceramic material known for its low density, high hardness, electrical insulation, and thermal stability. Bearings made with Si₃N₄ balls can operate at higher speeds, lower friction, and in more extreme environments than conventional steel bearings.

Silicon Nitride Ball Bearing Benefits

-

High-Speed with Reduced Heat

Silicon nitride (Si₃N₄) balls have only 40% of the density of steel, which drastically lowers rotational inertia and rolling friction. This enables bearings to sustain higher n·dm values (up to 2.0×10⁶ mm/min under grease lubrication) while maintaining temperature rise within a safe 8–12 °C margin. The reduced centrifugal load helps extend grease life, improves high-rpm acceleration response, and minimizes dynamic imbalance in CNC spindles, turbines, and EV motors. -

Electrical Insulation and EDM Protection

Both hybrid and full ceramic configurations naturally interrupt the current path between shaft and housing. This prevents electrical discharge machining (EDM) and fluting damage in VFD-driven motors or high-frequency drives. Si₃N₄ ceramic balls have a resistivity above 10¹⁴ Ω·cm, acting as a stable electrical barrier. This feature enhances bearing reliability in inverter-fed systems and significantly extends service intervals—often doubling the mean time between failures compared with steel bearings. -

Dimensional Stability Under Load

Precision-ground raceways combined with optimized contact angles (15°, 25°, or 30°) maintain structural stiffness and uniform load distribution at high speeds. The low thermal expansion coefficient (3.2×10⁻⁶ /K) of Si₃N₄ minimizes internal clearance shifts under temperature gradients. In spindle and precision machining setups, this ensures surface finish repeatability within 0.2–0.4 µm Ra and runout stability within 2–5 µm, reducing geometric drift and vibration amplitude during long duty cycles. -

Corrosion and Non-Magnetic Adaptability

Full-ceramic or stainless/PEEK hybrid versions resist acids, alkalis, and humid environments where steel bearings would corrode. Their non-magnetic nature makes them suitable for sensitive applications such as vacuum chambers, magnetic measurement systems, and chemical dosing pumps. The absence of metallic contamination ensures consistent torque and cleanroom compatibility, even in Class 100 or ISO 5 environments. -

Predictable Service Life and Data Consistency

When matched with appropriate sealing and lubrication systems, Si₃N₄ ceramic ball bearings demonstrate highly stable temperature rise and vibration trends throughout the operating cycle. This predictability simplifies maintenance planning and allows condition monitoring systems to forecast replacement based on quantitative parameters (temperature ≤ +15 °C above baseline; vibration ≤ 1.2× initial RMS). Users typically observe 2–5 × longer service life than standard steel bearings in comparable duty conditions.

Silicon Nitride Ceramic Ball Bearing Properties

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

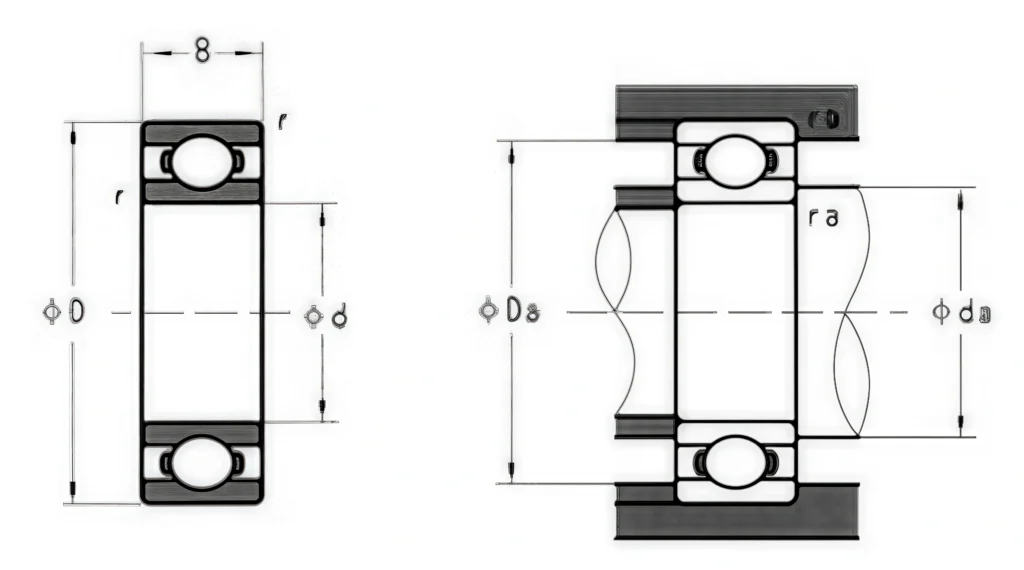

Silicon Nitride Bearing Specifications

| Silicon Nitride Bearing | |||||||||

| Specific size of bearings | Installation size | ||||||||

| Item No. | Bearing Mode(mm) | Inner Diameter (mm) | Outer Diameter (mm) | Height (mm) | R minimum | da-min | da-max | Da-max | ra-max |

| AT-DHG-ZC684CE | 684CE | 4 | 9 | 2.5 | 0.1 | 4.8 | / | 8.2 | 0.1 |

| AT-DHG-ZC694CE | 694CE | 4 | 0.15 | 5.2 | / | 9.8 | 0.15 | 0.15 | |

| AT-DHG-ZC604CE | 604CE | 4 | 0.2 | 5.6 | / | 10.4 | 0.2 | 0.2 | |

| AT-DHG-ZC624CE | 624CE | 5 | 0.2 | 5.6 | / | 11.4 | 0.2 | 0.2 | |

| AT-DHG-ZC634CE | 634CE | 5 | 0.3 | 6 | / | 14 | 0.3 | 0.3 | |

| AT-DHG-ZC685CE | 685CE | 5 | 11 | 3 | 0.15 | 6.2 | / | 9.8 | 0.15 |

| AT-DHG-ZC695CE | 695CE | 4 | 0.2 | 6.6 | / | 11.4 | 0.2 | 0.2 | |

| AT-DHG-ZC605CE | 605CE | 5 | 0.2 | 6.6 | / | 12.4 | 0.2 | 0.2 | |

| AT-DHG-ZC625CE | 625CE | 5 | 0.3 | 7 | / | 14 | 0.3 | 0.3 | |

| AT-DHG-ZC635CE | 635CE | 6 | 0.3 | 7 | / | 17 | 0.3 | 0.3 | |

| AT-DHG-ZC686CE | 686CE | 6 | 13 | 3.5 | 0.15 | 7.2 | / | 11.8 | 0.15 |

| AT-DHG-ZC696CE | 696CE | 5 | 0.2 | 7.6 | / | 13.4 | 0.2 | 0.2 | |

| AT-DHG-ZC606CE | 606CE | 6 | 0.3 | 8 | / | 15 | 0.3 | 0.3 | |

| AT-DHG-ZC626CE | 626CE | 6 | 0.3 | 8 | / | 17 | 0.3 | 0.3 | |

| AT-DHG-ZC636CE | 636CE | 7 | 0.3 | 8 | / | 20 | 0.3 | 0.3 | |

| AT-DHG-ZC687CE | 687CE | 7 | 14 | 3.5 | 0.15 | 8.2 | / | 12.8 | 0.15 |

| AT-DHG-ZC697CE | 697CE | 5 | 0.3 | 9 | / | 15 | 0.3 | 0.3 | |

| AT-DHG-ZC607CE | 607CE | 6 | 0.3 | 9 | / | 17 | 0.3 | 0.3 | |

| AT-DHG-ZC627CE | 627CE | 7 | 0.3 | 9 | / | 20 | 0.3 | 0.3 | |

| AT-DHG-ZC637CE | 637CE | 9 | 0.3 | 9 | / | 24 | 0.3 | 0.3 | |

| AT-DHG-ZC688CE | 688CE | 8 | 16 | 4 | 0.2 | 9.6 | / | 14.4 | 0.2 |

| AT-DHG-ZC698CE | 698CE | 6 | 0.3 | 10 | / | 17 | 0.3 | 0.3 | |

| AT-DHG-ZC608CE | 608CE | 7 | 0.3 | 10 | / | 20 | 0.3 | 0.3 | |

| AT-DHG-ZC628CE | 628CE | 8 | 0.3 | 10 | / | 22 | 0.3 | 0.3 | |

| AT-DHG-ZC638CE | 638CE | 9 | 0.3 | 10 | / | 26 | 0.3 | 0.3 | |

| AT-DHG-ZC689CE | 689CE | 9 | 17 | 4 | 0.2 | 10.6 | / | 15.4 | 0.2 |

| AT-DHG-ZC699CE | 699CE | 6 | 0.3 | 11 | / | 18 | 0.3 | 0.3 | |

| AT-DHG-ZC609CE | 609CE | 7 | 0.3 | 11 | / | 22 | 0.3 | 0.3 | |

| AT-DHG-ZC629CE | 629CE | 8 | 0.3 | 11 | / | 24 | 0.3 | 0.3 | |

| AT-DHG-ZC639CE | 639CE | 10 | 0.6 | 13 | / | 26 | 0.6 | 0.6 | |

| AT-DHG-ZC6800CE | 6800CE | 10 | 19 | 5 | 0.3 | 12 | 12 | 17 | 0.3 |

| AT-DHG-ZC6900CE | 6900CE | 6 | 0.3 | 12 | 12.5 | 20 | 0.3 | 0.3 | |

| AT-DHG-ZC6000CE | 6000CE | 8 | 0.3 | 12 | 13 | 24 | 0.3 | 0.3 | |

| AT-DHG-ZC6200CE | 6200CE | 9 | 0.6 | 14 | 16 | 26 | 0.6 | 0.6 | |

| AT-DHG-ZC6300CE | 6300CE | 11 | 0.6 | 14 | 16.5 | 31 | 0.6 | 0.6 | |

| AT-DHG-ZC6801CE | 6801CE | 12 | 21 | 5 | 0.3 | 14 | 14 | 19 | 0.3 |

| AT-DHG-ZC6901CE | 6901CE | 6 | 0.3 | 14 | 14.5 | 22 | 0.3 | 0.3 | |

| AT-DHG-ZC16001CE | 16001CE | 7 | 0.3 | 14 | / | 26 | 0.3 | 0.3 | |

| AT-DHG-ZC6001CE | 6001CE | 8 | 0.3 | 14 | 15.5 | 26 | 0.3 | 0.3 | |

| AT-DHG-ZC6201CE | 6201CE | 10 | 0.6 | 16 | 17 | 28 | 0.6 | 0.6 | |

| AT-DHG-ZC6301CE | 6301CE | 12 | 1 | 17 | 18 | 32 | 1 | 1 | |

| AT-DHG-ZC6802CE | 6802CE | 15 | 24 | 5 | 0.3 | 17 | 17 | 22 | 0.3 |

| AT-DHG-ZC6902CE | 6902CE | 7 | 0.3 | 17 | 17 | 26 | 0.3 | 0.3 | |

| AT-DHG-ZC16002CE | 16002CE | 8 | 0.3 | 17 | / | 30 | 0.3 | 0.3 | |

| AT-DHG-ZC6002CE | 6002CE | 9 | 0.3 | 17 | 19 | 30 | 0.3 | 0.3 | |

| AT-DHG-ZC6202CE | 6202CE | 11 | 0.6 | 19 | 20.5 | 31 | 0.3 | 0.3 | |

| AT-DHG-ZC6302CE | 6302CE | 13 | 1 | 20 | 22.5 | 37 | 1 | 1 | |

| AT-DHG-ZC6803CE | 6803CE | 17 | 26 | 5 | 0.3 | 19 | 19 | 24 | 0.3 |

| AT-DHG-ZC6903CE | 6903CE | 7 | 0.3 | 19 | 19.5 | 28 | 0.3 | 0.3 | |

| AT-DHG-ZC16003CE | 16003CE | 8 | 0.3 | 19 | / | 33 | 0.3 | 0.3 | |

| AT-DHG-ZC6003CE | 6003CE | 10 | 0.3 | 19 | 21.5 | 33 | 0.3 | 0.3 | |

| AT-DHG-ZC6203CE | 6203CE | 12 | 0.6 | 21 | 23.5 | 36 | 0.6 | 0.6 | |

| AT-DHG-ZC6303CE | 6303CE | 14 | 1 | 22 | 25.5 | 42 | 1 | 1 | |

| AT-DHG-ZC6403CE | 6403CE | 17 | 1.1 | 23.5 | / | 55.5 | 1 | 1 | |

| AT-DHG-ZC6804CE | 6804CE | 20 | 32 | 7 | 0.3 | 22 | 22.5 | 30 | 0.3 |

| AT-DHG-ZC6904CE | 6904CE | 9 | 0.3 | 22 | 24 | 35 | 0.3 | 0.3 | |

| AT-DHG-ZC16004CE | 16004CE | 8 | 0.3 | 22 | / | 40 | 0.3 | 0.3 | |

| AT-DHG-ZC6004CE | 6004CE | 12 | 0.6 | 24 | 25.5 | 38 | 0.6 | 0.6 | |

| AT-DHG-ZC6204CE | 6204CE | 14 | 1 | 25 | 26.5 | 42 | 1 | 1 | |

| AT-DHG-ZC6304CE | 6304CE | 15 | 1.1 | 26.5 | 28 | 45.5 | 1 | 1 | |

| AT-DHG-ZC6404CE | 6404CE | 19 | 1.1 | 26.5 | / | 65.5 | 1 | 1 | |

| AT-DHG-ZC6805CE | 6805CE | 25 | 37 | 7 | 0.3 | 27 | 27 | 35 | 0.3 |

| AT-DHG-ZC6905CE | 6905CE | 9 | 0.3 | 27 | 28.5 | 40 | 0.3 | 0.3 | |

| AT-DHG-ZC16005CE | 16005CE | 8 | 0.3 | 27 | / | 45 | 0.3 | 0.3 | |

| AT-DHG-ZC6005CE | 6005CE | 12 | 0.6 | 29 | 30 | 43 | 0.6 | 0.6 | |

| AT-DHG-ZC6205CE | 6205CE | 15 | 1 | 30 | 32 | 47 | 1 | 1 | |

| AT-DHG-ZC6305CE | 6305CE | 17 | 1.1 | 31.5 | 36 | 55.5 | 1 | 1 | |

| AT-DHG-ZC6405CE | 6405CE | 21 | 1.5 | 33 | / | 72 | 1.5 | 1.5 | |

| AT-DHG-ZC6806CE | 6806CE | 30 | 42 | 7 | 0.3 | 32 | 32 | 50 | 1 |

| AT-DHG-ZC6906CE | 6906CE | 9 | 0.3 | 32 | 34 | 57 | 1 | 1 | |

| AT-DHG-ZC16006CE | 16006CE | 9 | 0.3 | 32 | 42.5 | 65.5 | 1 | 1 | |

| AT-DHG-ZC6006CE | 6006CE | 13 | 1 | 35 | 36.5 | 53 | 1 | 1 | |

| AT-DHG-ZC6206CE | 6206CE | 16 | 1 | 35 | 38.5 | 60 | 1 | 1 | |

| AT-DHG-ZC6306CE | 6306CE | 19 | 1.1 | 36.5 | 42.5 | 68.5 | 1 | 1 | |

| AT-DHG-ZC6406CE | 6406CE | 23 | 1.5 | 54 | / | 82 | 2 | 2 | |

| AT-DHG-ZC6807CE | 6807CE | 35 | 47 | 7 | 0.3 | 37 | 37 | 45 | 0.3 |

| AT-DHG-ZC6907CE | 6907CE | 10 | 0.6 | 39 | 39 | 51 | 0.6 | 0.6 | |

| AT-DHG-ZC16007CE | 16007CE | 9 | 0.3 | 37 | / | 60 | 0.3 | 0.3 | |

| AT-DHG-ZC6007CE | 6007CE | 14 | 1 | 40 | 41.5 | 57 | 1 | 1 | |

| AT-DHG-ZC6207CE | 6207CE | 17 | 1.1 | 41.5 | 44.5 | 65.5 | 1 | 1 | |

| AT-DHG-ZC6307CE | 6307CE | 80 | 21 | 1.5 | 43 | 47 | 72 | 1.5 | |

| AT-DHG-ZC6407CE | 6407CE | 25 | 1.5 | 43 | / | 92 | 1.5 | 1.5 | |

| AT-DHG-ZC6808CE | 6808CE | 40 | 52 | 7 | 0.3 | 42 | 42 | 50 | 0.3 |

| AT-DHG-ZC6908CE | 6908CE | 12 | 0.6 | 44 | 46 | 58 | 0.6 | 0.6 | |

| AT-DHG-ZC16008CE | 16008CE | 9 | 0.3 | 42 | / | 66 | 0.3 | 0.3 | |

| AT-DHG-ZC6008CE | 6008CE | 15 | 1 | 45 | 47.5 | 63 | 1 | 1 | |

| AT-DHG-ZC6208CE | 6208CE | 18 | 1.1 | 46.5 | 50.5 | 73.5 | 1 | 1 | |

| AT-DHG-ZC6308CE | 6308CE | 23 | 1.5 | 48 | 53 | 80 | 1.5 | 1.5 | |

| AT-DHG-ZC6408CE | 6408CE | 27 | 2 | 49 | / | 101 | 2 | 2 | |

| AT-DHG-ZC6809CE | 6809CE | 45 | 58 | 7 | 0.3 | 47 | 47.5 | 56 | 0.3 |

| AT-DHG-ZC6909CE | 6909CE | 12 | 0.6 | 49 | 50 | 64 | 0.6 | 0.6 | |

| AT-DHG-ZC16009CE | 16009CE | 10 | 0.6 | 49 | / | 71 | 0.6 | 0.6 | |

| AT-DHG-ZC6009CE | 6009CE | 16 | 1 | 50 | 53.5 | 70 | 1 | 1 | |

| AT-DHG-ZC6209CE | 6209CE | 19 | 1.1 | 51.5 | 55.5 | 78.5 | 1 | 1 | |

| AT-DHG-ZC6309CE | 6309CE | 25 | 1.5 | 53 | 61.5 | 92 | 1.5 | 1.5 | |

| AT-DHG-ZC6409CE | 6409CE | 29 | 2 | 54 | / | 111 | 2 | 2 | |

| AT-DHG-ZC6810CE | 6810CE | 50 | 65 | 7 | 0.3 | 52 | 52.5 | 63 | 0.3 |

| AT-DHG-ZC6910CE | 6910CE | 12 | 0.6 | 54 | 55 | 68 | 0.6 | 0.6 | |

| AT-DHG-ZC16010CE | 16010CE | 10 | 0.6 | 54 | / | 76 | 0.6 | 0.6 | |

| AT-DHG-ZC6010CE | 6010CE | 16 | 1 | 55 | 58.5 | 75 | 1 | 1 | |

| AT-DHG-ZC6210CE | 6210CE | 20 | 1.1 | 56.5 | 60 | 83.2 | 1 | 1 | |

| AT-DHG-ZC6310CE | 6310CE | 27 | 2 | 59 | 68 | 101 | 2 | 2 | |

| AT-DHG-ZC6410CE | 6410CE | 31 | 2.1 | 61 | / | 119 | 2 | 2 | |

| AT-DHG-ZC6811CE | 6811CE | 55 | 72 | 9 | 0.3 | 57 | 59 | 70 | 0.3 |

| AT-DHG-ZC6911CE | 6911CE | 13 | 1 | 60 | 61.5 | 75 | 1 | 1 | |

| AT-DHG-ZC16011CE | 16011CE | 11 | 0.6 | 59 | / | 86 | 0.6 | 0.6 | |

| AT-DHG-ZC6011CE | 6011CE | 18 | 1.1 | 61.5 | 64 | 83.5 | 1 | 1 | |

| AT-DHG-ZC6211CE | 6211CE | 21 | 1.5 | 63 | 66.5 | 92 | 1.5 | 1.5 | |

| AT-DHG-ZC6311CE | 6311CE | 29 | 2 | 64 | 72.5 | 111 | 2 | 2 | |

| AT-DHG-ZC6411CE | 6411CE | 33 | 2.1 | 66 | / | 129 | 2 | 2 | |

| AT-DHG-ZC6812CE | 6812CE | 60 | 78 | 10 | 0.3 | 62 | 64 | 76 | 0.3 |

| AT-DHG-ZC6912CE | 6912CE | 13 | 1 | 65 | 66 | 80 | 1 | 1 | |

| AT-DHG-ZC16012CE | 16012CE | 11 | 0.6 | 64 | / | 91 | 0.6 | 0.6 | |

| AT-DHG-ZC6012CE | 6012CE | 18 | 1.1 | 66.5 | 69 | 88.5 | 1 | 1 | |

| AT-DHG-ZC6212CE | 6212CE | 22 | 1.5 | 68 | 74.5 | 102 | 1.5 | 1.5 | |

| AT-DHG-ZC6312CE | 6312CE | 31 | 2.1 | 71 | 79 | 119 | 2 | 2 | |

| AT-DHG-ZC6412CE | 6412CE | 35 | 2.1 | 71 | 139 | 2 | 2 | ||

| AT-DHG-ZC6813CE | 6813CE | 65 | 85 | 10 | 0.6 | 69 | 69 | 81 | 0.6 |

| AT-DHG-ZC6913CE | 6913CE | 13 | 1 | 70 | 71.5 | 85 | 1 | 1 | |

| AT-DHG-ZC16013CE | 16013CE | 11 | 0.6 | 69 | / | 96 | 0.6 | 0.6 | |

| AT-DHG-ZC6013CE | 6013CE | 18 | 1.1 | 71.5 | 73 | 93.5 | 1 | 1 | |

| AT-DHG-ZC6213CE | 6213CE | 23 | 1.5 | 73 | 80 | 112 | 1.5 | 1.5 | |

| AT-DHG-ZC6313CE | 6313CE | 140 | 33 | 2.1 | 76 | 85.5 | 129 | 2 | |

| AT-DHG-ZC6814CE | 6814CE | 70 | 90 | 10 | 0.6 | 74 | 74.5 | 86 | 0.6 |

| AT-DHG-ZC6914CE | 6914CE | 16 | 1 | 75 | 77.5 | 95 | 1 | 1 | |

| AT-DHG-ZC16014CE | 16014CE | 13 | 0.6 | 74 | / | 106 | 0.6 | 0.6 | |

| AT-DHG-ZC6014CE | 6014CE | 20 | 1.1 | 76.5 | 80.5 | 103.5 | 1 | 1 | |

| AT-DHG-ZC6214CE | 6214CE | 24 | 1.5 | 78 | 84 | 117 | 1.5 | 1.5 | |

| AT-DHG-ZC6314CE | 6314CE | 35 | 2.1 | 81 | 92 | 139 | 2 | 2 | |

| AT-DHG-ZC6815CE | 6815CE | 75 | 95 | 10 | 0.6 | 79 | 79.5 | 91 | 0.6 |

| AT-DHG-ZC6915CE | 6915CE | 16 | 1 | 80 | 82 | 100 | 1 | 1 | |

| AT-DHG-ZC16015CE | 16015CE | 13 | 0.6 | 79 | / | 111 | 0.6 | 0.6 | |

| AT-DHG-ZC6015CE | 6015CE | 20 | 1.1 | 81.5 | 85.5 | 108.5 | 1 | 1 | |

| AT-DHG-ZC6215CE | 6215CE | 25 | 1.5 | 83 | 90 | 122 | 1.5 | 1.5 | |

| AT-DHG-ZC6816CE | 6816CE | 80 | 100 | 10 | 0.6 | 84 | 84.5 | 96 | 0.6 |

| AT-DHG-ZC6916CE | 6916CE | 16 | 1 | 85 | 87.5 | 105 | 1 | 1 | |

| AT-DHG-ZC16016CE | 16016CE | 14 | 0.6 | 84 | / | 121 | 0.6 | 0.6 | |

| AT-DHG-ZC6016CE | 6016CE | 22 | 1.1 | 86.5 | 91 | 118.5 | 1 | 1 | |

| AT-DHG-ZC6216CE | 6216CE | 26 | 2 | 89 | 95.5 | 131 | 2 | 2 | |

| AT-DHG-ZC6817CE | 6817CE | 85 | 110 | 13 | 1 | 90 | 90.5 | 105 | 1 |

| AT-DHG-ZC6917CE | 6917CE | 18 | 1.1 | 91.5 | 94.5 | 113.5 | 1 | 1 | |

| AT-DHG-ZC16017CE | 16017CE | 14 | 0.6 | 89 | / | 126 | 0.6 | 0.6 | |

| AT-DHG-ZC6017CE | 6017CE | 22 | 1.1 | 91.5 | 96 | 123.5 | 1 | 1 | |

| AT-DHG-ZC6217CE | 6217CE | 28 | 2 | 94 | 102 | 141 | 2 | 2 | |

| AT-DHG-ZC6818CE | 6818CE | 90 | 115 | 13 | 1 | 95 | 95.5 | 110 | 1 |

| AT-DHG-ZC6918CE | 6918CE | 18 | 1.1 | 96.5 | 98.5 | 118.5 | 1 | 1 | |

| AT-DHG-ZC16018CE | 16018CE | 16 | 1 | 95 | / | 135 | 1 | 1 | |

| AT-DHG-ZC6018CE | 6018CE | 24 | 1.5 | 98 | 103 | 132 | 1.5 | 1.5 | |

| AT-DHG-ZC6819CE | 6819CE | 95 | 120 | 13 | 1 | 100 | 102 | 115 | 1 |

| AT-DHG-ZC6919CE | 6919CE | 18 | 1.1 | 101.5 | 104 | 123.5 | 1 | 1 | |

| AT-DHG-ZC16019CE | 16019CE | 16 | 1 | 100 | / | 140 | 1 | 1 | |

| AT-DHG-ZC6019CE | 6019CE | 24 | 1.5 | 103 | 109 | 137 | 1.5 | 1.5 | |

| AT-DHG-ZC6820CE | 6820CE | 100 | 125 | 13 | 1 | 105 | 106 | 120 | 1 |

| AT-DHG-ZC6920CE | 6920CE | 20 | 1.1 | 106.5 | 111 | 133.5 | 1 | 1 | |

| AT-DHG-ZC16020CE | 16020CE | 16 | 1 | 105 | / | 145 | 1 | 1 | |

| AT-DHG-ZC6020CE | 6020CE | 24 | 1.5 | 108 | 113 | 142 | 1.5 | 1.5 | |

| AT-DHG-ZC6821CE | 6821CE | 105 | 130 | 13 | 1 | 110 | 111 | 125 | 1 |

| AT-DHG-ZC6921CE | 6921CE | 20 | 1.1 | 111.5 | 116 | 138.5 | 1 | 1 | |

| AT-DHG-ZC6822CE | 6822CE | 110 | 140 | 16 | 1 | 115 | 117 | 135 | 1 |

| AT-DHG-ZC6922CE | 6922CE | 20 | 1.1 | 116.5 | 121 | 143.5 | 1 | 1 | |

| AT-DHG-ZC6824CE | 6824CE | 120 | 150 | 16 | 1 | 125 | 127 | 145 | 1 |

Silicon Nitride Ceramic Ball Bearings Packaging

- Anti-static sealed PE bags

- Foam-padded inner box with product label

![]()