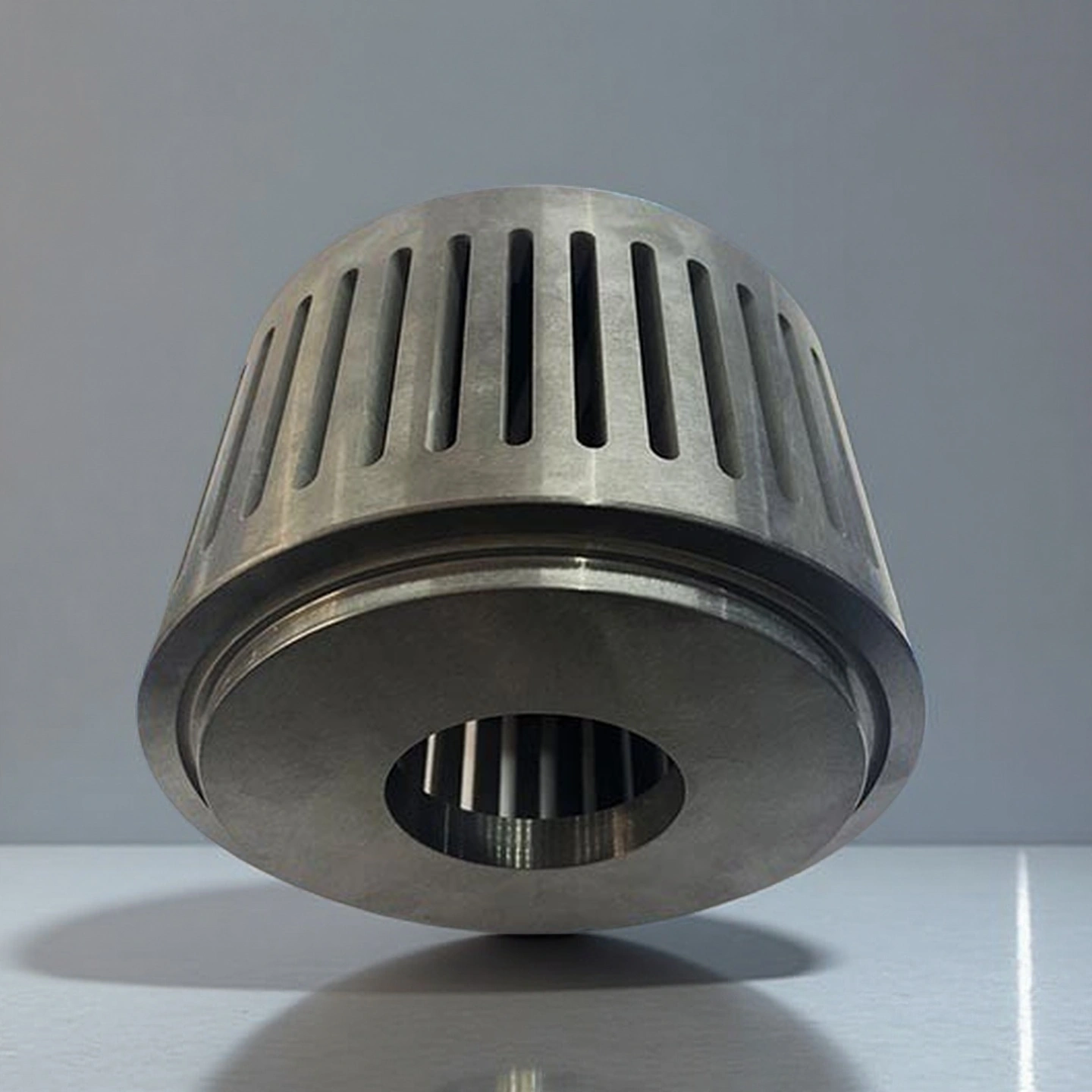

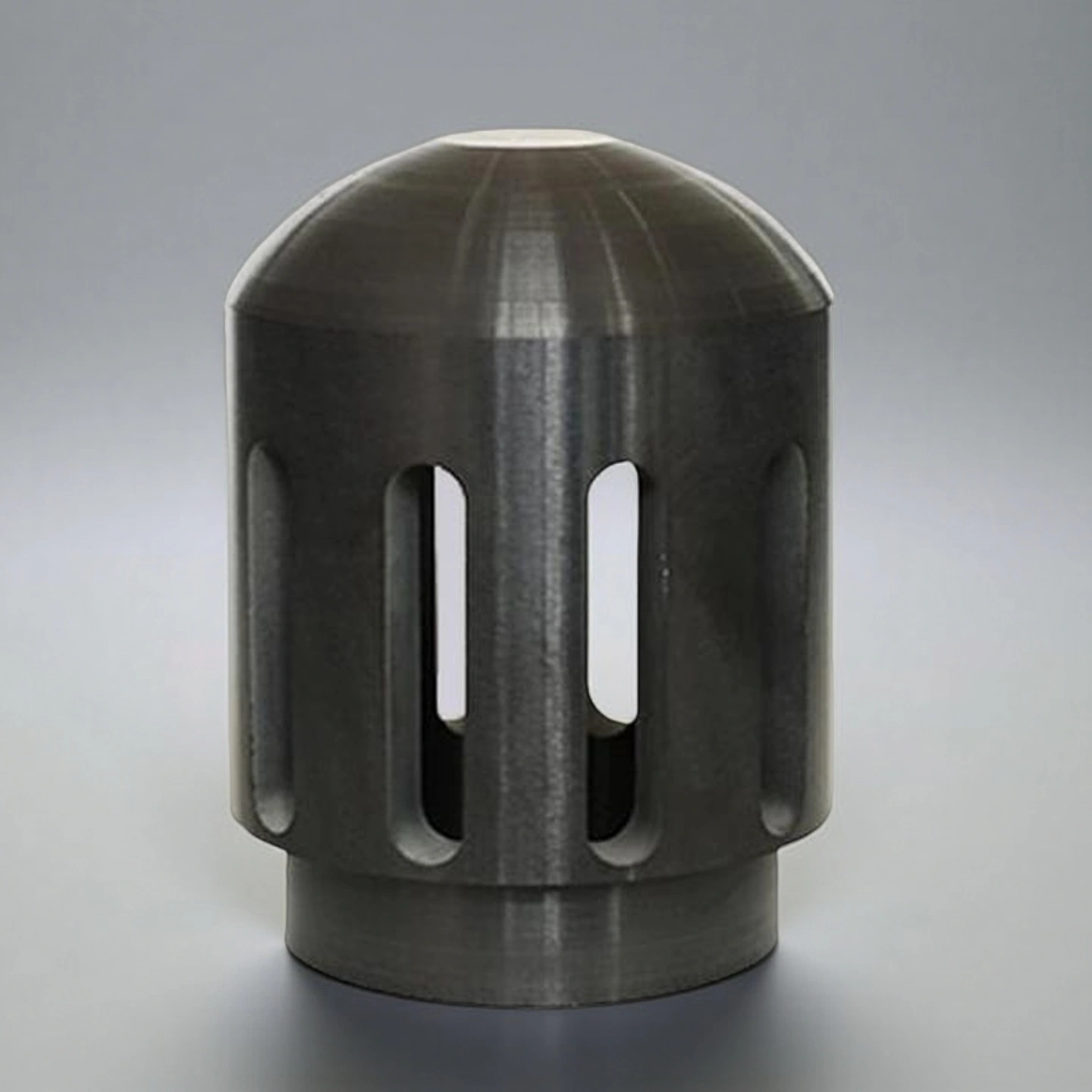

The silicon nitride ceramic grading wheel is a full ceramic classifier wheel designed for air classifiers, jet mills, and ACM mills handling high-value fine powders. It combines the high strength and low density of Si3N4 with a balanced rotor structure to support high rotational speeds and narrow particle size distributions.

Silicon Nitride Ceramic Grading Wheel Benefits

- High wear resistance: Extends service life in abrasive powder environments.

- Non-metallic: Prevents contamination in high-purity powder processing.

- Thermal shock resistance: Suitable for rapid temperature changes in jet milling.

- Dimensional precision: Ensures consistent classification performance.

- Corrosion resistance: Withstands chemical exposure in fine powder systems.

Si3N4 Ceramic Grading Wheel Properties

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

Si3N4 Ceramic Grading Wheel Specifications

| Si3N4 Ceramic Grading Wheel | ||||

| Item No. | Outer Diameter(mm) | Inner Diameter(mm) | Height(mm) | Upper limit of linear speed m/s |

| AT-SIN-FJ001 | 100 | 75 | 80 | 70 |

| AT-SIN-FJ002 | 155 | 135 | 95 | 70 |

| AT-SIN-FJ003 | 250 | 220 | 100 | 70 |

| AT-SIN-FJ004 | 260 | 240 | 120 | 70 |

| AT-SIN-FJ005 | 315 | 265 | 120 | 70 |

Si3N4 Classifier Wheel Packaging

- Each silicon nitride ceramic grading wheel is wrapped with foam or soft cushioning material to protect blades and edges.