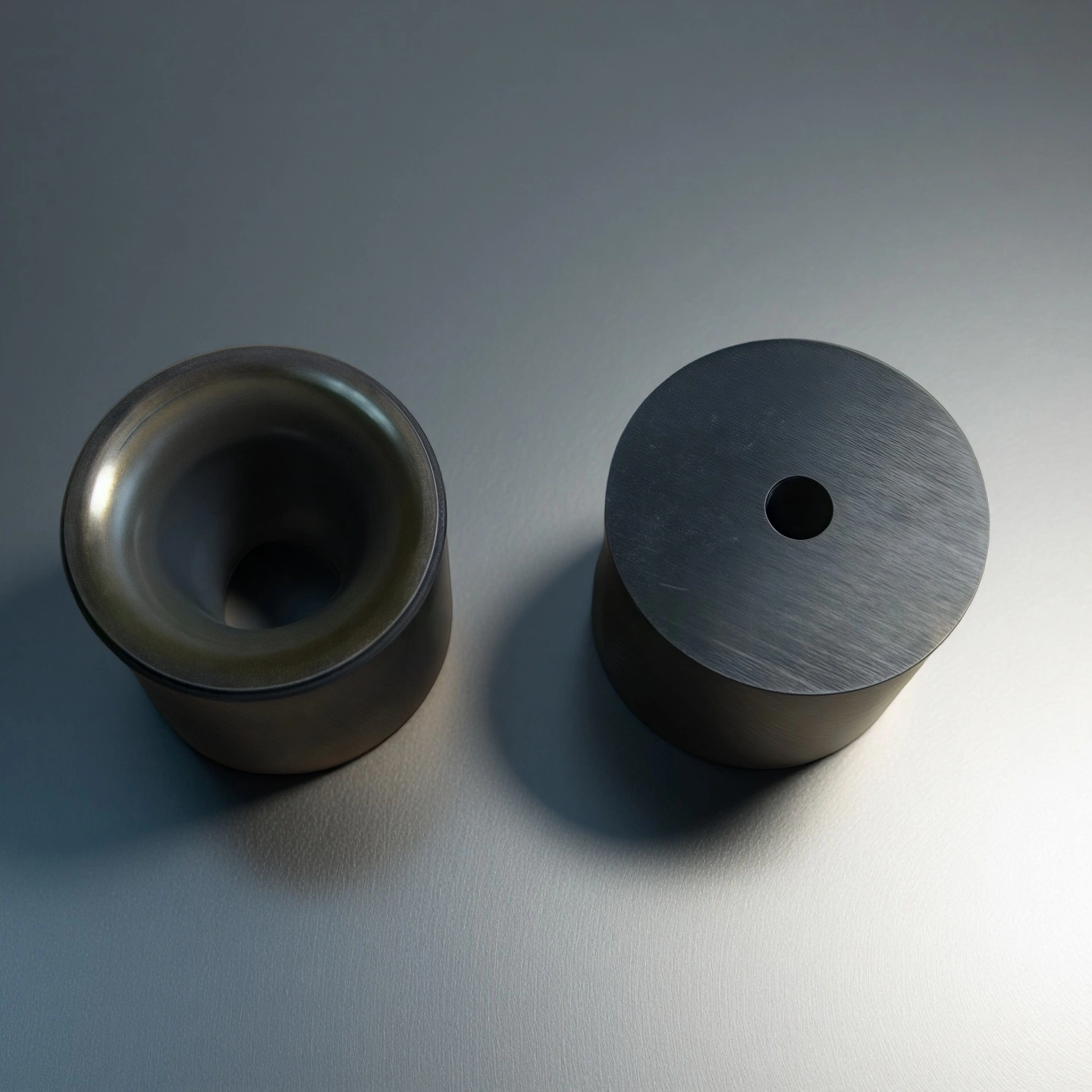

Silicon nitride ceramic wire drawing die is a precision die insert made from Si₃N₄ engineered ceramic, used to reduce the diameter of metal wire and optical fiber during drawing. The die controls wire size through a tapered approach zone, a calibrated bearing section, and an exit profile that shapes and stabilizes the drawn material.

Silicon Nitride Ceramic Wire Drawing Die Benefits

-

Stable Bore Geometry under Load

The high flexural strength of Si3N4 keeps the bore shape stable during drawing, which helps maintain consistent wire diameter over longer production runs. -

Reduced Metal Pickup on Wire Surface

Silicon nitride has no metallic binder phase, which reduces adhesion of copper, brass, or steel to the die and lowers the risk of scoring, scratches, and streaks on the wire surface. -

Extended Service Life versus Steel Dies

In comparable applications, silicon nitride ceramic wire drawing dies can reach several times the life of hardened steel dies, which helps reduce changeover frequency and unplanned stops. -

Suitable for High-Speed Drawing

The combination of high hardness, good thermal shock resistance, and moderate thermal conductivity supports stable performance in high-speed drawing with modern lubricants. -

Dimensional Precision for Downstream Processes

Tight bore tolerances and good roundness help keep wire ovality low, which reduces adjustments in downstream annealing, coating, or spooling operations.

Silicon Nitride Wire Drawing Die Properties

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

Si3N4 Ceramic Wire Drawing Die Specifications

| Si3N4 Ceramic Wire Drawing Die | |

| Item No. | Outer Diameter * Inner Diameter *Height (mm) |

| AT-SN-LX001 | 45*8*40 |

| AT-SN-LX002 | 45*10*40 |

| AT-SN-LX003 | 45*12*40 |

| AT-SN-LX004 | 45*14*40 |

| AT-SN-LX005 | 45*16*40 |

| AT-SN-LX006 | 45*17*40 |

| AT-SN-LX007 | 45*18*40 |

| AT-SN-LX008 | 45*20*40 |

| AT-SN-LX009 | 45*22*40 |

Silicon Nitride Ceramic Wire Drawing Die Packaging

- Each silicon nitride ceramic wire drawing die is packed in a separate cushioned box or foam slot to prevent chipping of the ceramic edges during transport.

![]()