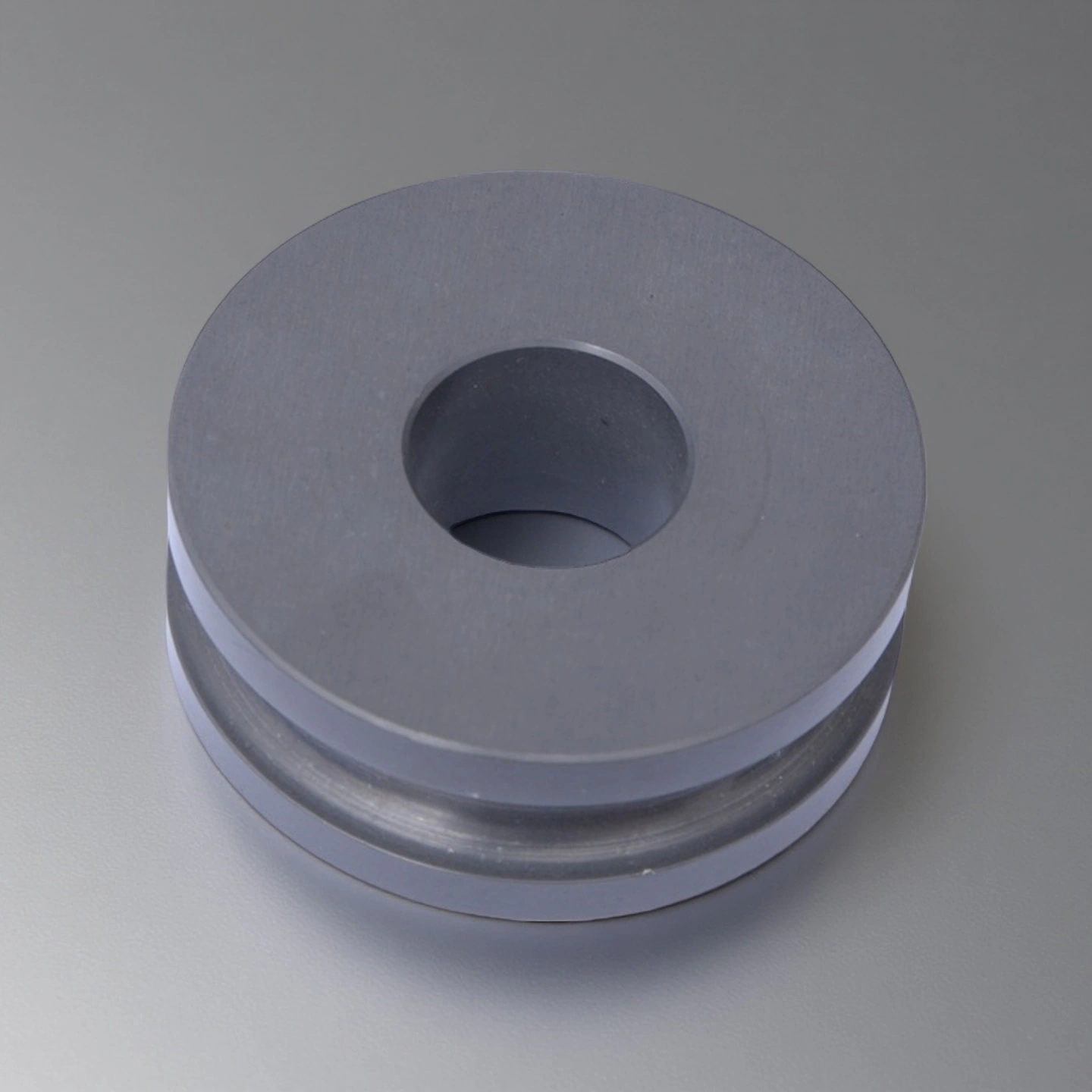

Silicon nitride ceramic wire wheel is a precision-machined Si₃N₄ guide component used to control the path, tension, and surface stability of wire, cable, welding wire, filament, or diamond wire during continuous production. The wheel is made from dense silicon nitride ceramic, a material with high flexural strength, excellent wear resistance, and stable performance at elevated temperatures. This combination allows the wire wheel to maintain groove accuracy and low-friction contact even under high line speed, cyclic loading, or abrasive environments.

Silicon Nitride Ceramic Wire Wheel Benefits

-

Stable geometry at high speed

Silicon nitride maintains flexural strength in the 600–900 MPa range, so the wire wheel resists deformation under high line tension and rotation. -

High wear resistance in the groove area

Si₃N₄ hardness is typically around 15 GPa, which helps reduce groove wear when guiding steel wire, welding wire, and hard alloy wires, extending replacement intervals. -

Low friction, polished wire contact

Polished ceramic grooves can reach sub-micron roughness levels; research on silicon nitride finishing shows nano-scale Ra values are achievable, which supports stable wire surface quality. -

Suitable for elevated temperature zones

Dense silicon nitride can be used continuously around 1000–1200 °C in air so that the same wheel can work near annealing, pre-heating, or drying sections without rapid degradation. -

Tight tolerances for concentricity and run-out

Ceramic wire wheels can be ground to tight bore tolerances and low run-out so that vibration and wire wandering are minimized on high-speed lines.

Si3N4 ceramic wire wheel Properties

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

Silicon Nitride Ceramic Wire Wheel Specifications

| Silicon Nitride Ceramic Wire Wheel | ||

| Item No. | Diameter (mm) | Thickness (mm) |

| AT-SIN-DL1001 | Customize | |

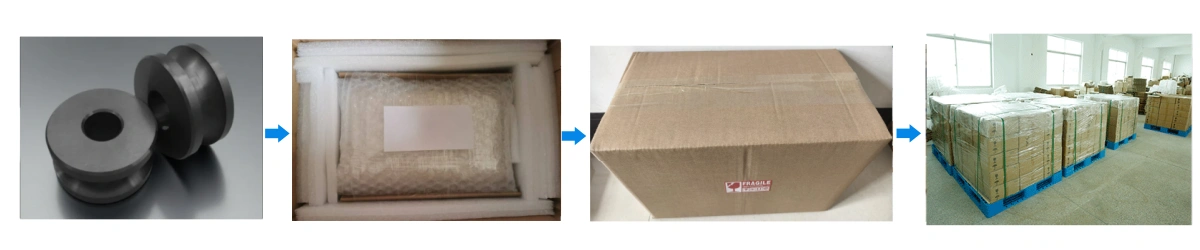

Si3N4 Ceramic Wire Guide Wheel Packaging

- Each silicon nitride ceramic wire wheel is wrapped in soft material to protect the groove and bore from impact.