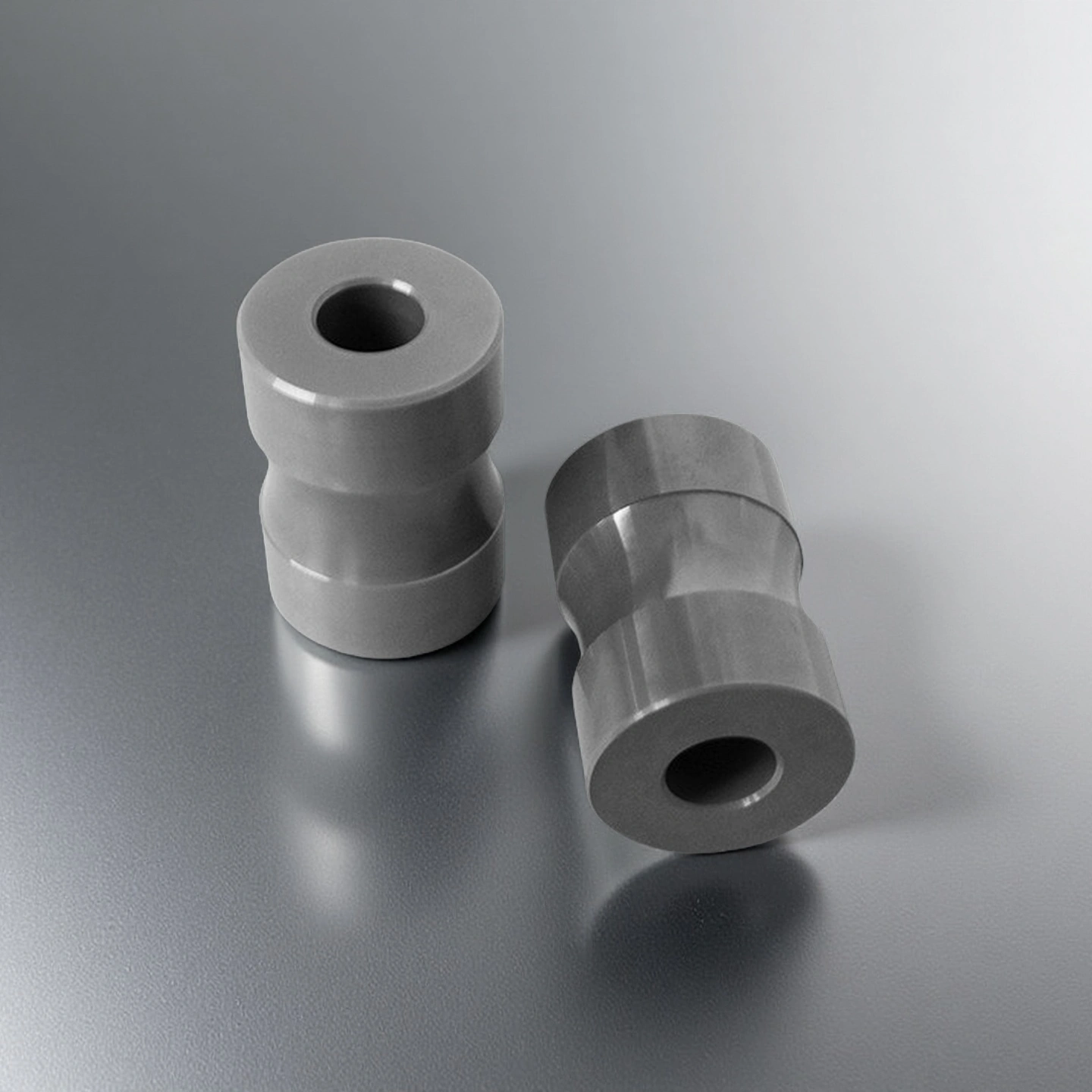

Silicon nitride welding rollers are ceramic rolls used in high-frequency electric resistance welding and forming stands to support, guide, and squeeze the tube during welding. Their low thermal expansion, high strength, and electrical insulation help stabilise the weld seam and extend roll life compared with tool steel rolls.

Silicon Nitride Welding Roller Benefits

-

Service life multiplier

In many HF-ERW lines, silicon nitride welding rollers can reach 10–20 times the service life of tool steel rolls when alignment, cooling, and stand conditions are controlled. -

Lower HF power and cooler operation

Ceramic weld rolls do not carry HF current and can reduce HF weld power demand, which keeps the weld stand cooler and lowers load on bearings and seals. -

Reduced metal build-up and better tube surface

Silicon nitride rolls show less metal pick-up on the groove and help maintain tube surface finish and weld seam stability, which can reduce scrap compared with steel rolls. -

Stable geometry under heat and load

The combination of high flexural strength, high compressive strength, and low thermal expansion keeps the groove shape and run-out stable under line load and temperature changes. -

Non-conductive in HF fields

Silicon nitride is electrically insulating, so the welding roller does not draw HF current and allows more controlled power distribution in the weld zone.

Si₃N₄ Welding Roller Properties

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

Si3N4 Welding Roller Specifications

| Silicon Nitride Welding Roller | ||

| Item No. | Diameter (mm) | Thickness (mm) |

| AT-SN-HG1001 | Customize | |

Silicon Nitride Weld Roll Packaging

- Each roller is individually packed in shock-resistant foam and sealed in moisture-proof bags.

![]()