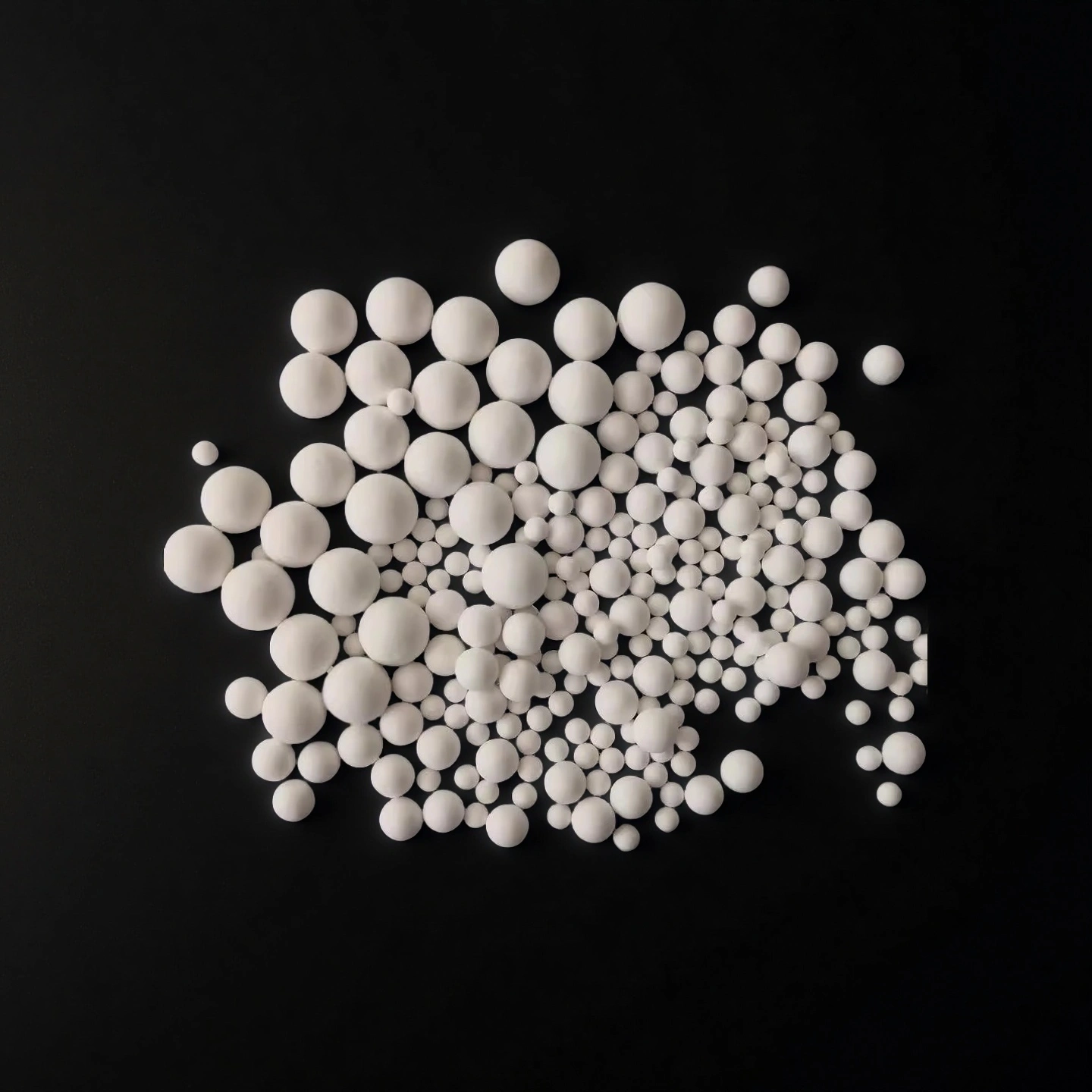

Zirconia Toughened Alumina (ZTA) grinding beads—also called ZTA composite media—are ceramic beads made by dispersing fine zirconia (ZrO₂) within an alumina (Al₂O₃) matrix. The zirconia phase “toughens” the alumina through transformation-toughening and crack-deflection, giving the beads higher fracture resistance than pure alumina while keeping density and contamination lower than fully-stabilized zirconia. The result is a balanced grinding media for wet milling and dispersion where you need narrow PSD, stable throughput, and controlled wear.

ZTA Grinding Beads Benefits

- Balanced efficiency/contamination — composite density delivers throughput without excessive metallic wear.

- Low breakage & fines — toughened microstructure reduces fracture under high shear.

- High roundness surface — smooth circulation, predictable residence time, stable PSD.

- Tight size tolerance — improved screen compatibility and repeatable scale-up.

- Cleanliness managed — controlled extractables for sensitive formulations.

Zirconia Alumina Grinding Beads Properties

| Physical Properties | |||||||

|---|---|---|---|---|---|---|---|

| Specific Gravity | Bulk Density | Mohs Hardness | Vickers Hardness | Compressive Strength | Wear per Ton | Sphericity | Packaging |

| >3.6kg/dm³ | >2.1kg/L | 8 | >1100kg/mm² | 900N (2mm) | ≈0.08kg/T | 96% | 25kg/barrel |

ZTA Grinding Beads Specifications

| ZTA Grading Beads | |

| Item No. | Diameter (mm) |

| AT-NZC8-001 | 1.0-1.3 |

| AT-NZC10-002 | 1.3-1.7 |

| AT-NZC12-003 | 1.5-2.0 |

| AT-NZC20-004 | 2.0-2.5 |

| AT-NZC25-005 | 2.5-3.0 |

| AT-NZC30-006 | 3.0-3.5 |

| AT-NZC35-007 | 3.5-4.0 |

| AT-NZC40-008 | 4.0-4.5 |

| AT-NZC45-009 | 4.5-5.0 |

Zirconia alumina grinding beads Packaging

- Moisture-barrier inner bags in pails or drums with tamper-evident seals.